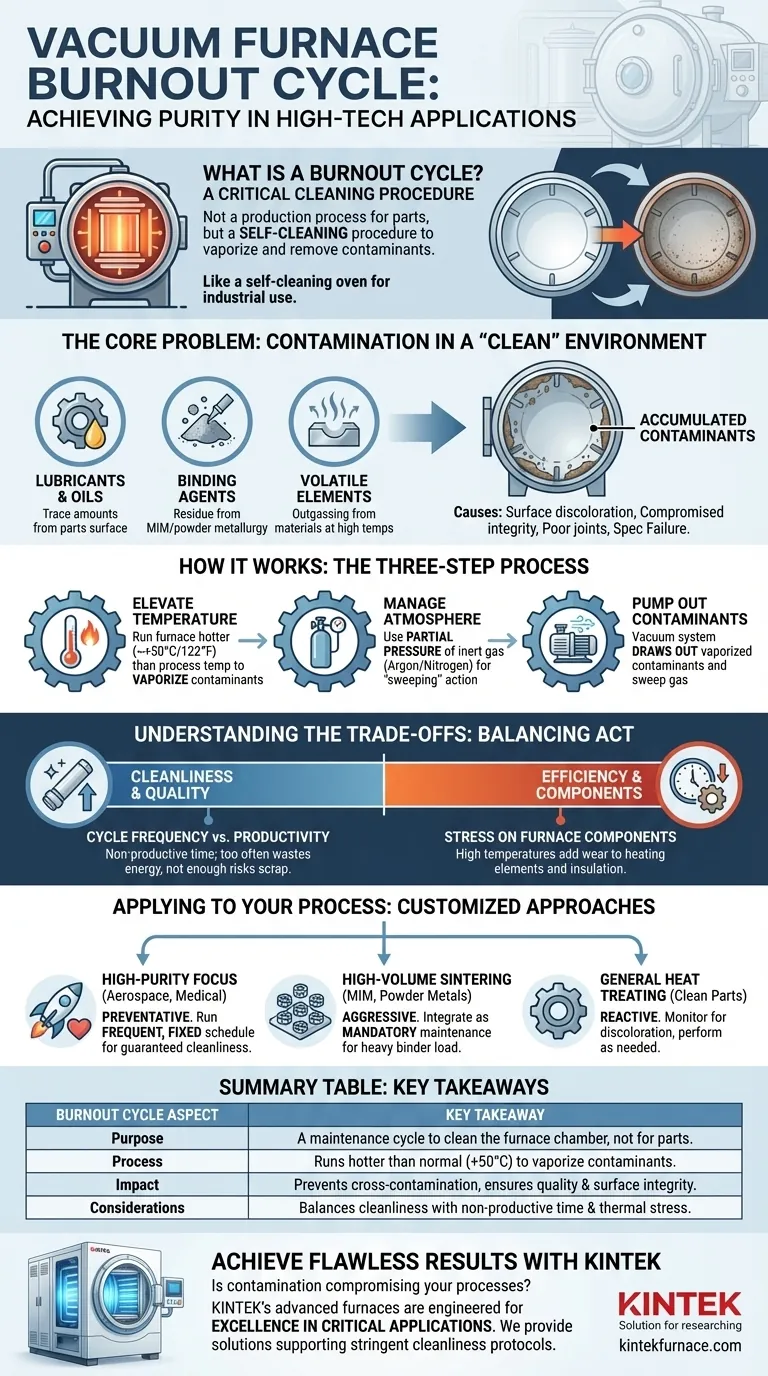

In a vacuum furnace, a burnout cycle is a periodic, high-temperature maintenance run performed without any parts inside. Its purpose is to vaporize and remove contaminants that have accumulated within the furnace chamber from previous processing cycles, ensuring the cleanliness required for future high-quality work.

The burnout cycle is not a production process for treating parts; it is a critical cleaning procedure for the furnace itself. Think of it as a self-cleaning oven cycle, but for a high-tech industrial environment, designed to maintain the integrity of the vacuum atmosphere and prevent cross-contamination between batches.

The Core Problem: Contamination in a "Clean" Environment

A vacuum furnace's primary advantage is its ability to heat materials in a controlled environment, free from the oxygen and other gases that cause oxidation and contamination. However, over time, the "clean" interior of the furnace inevitably becomes dirty.

Where Do Contaminants Come From?

Even with meticulous preparation, contaminants are introduced into the furnace. Common sources include:

- Lubricants and Oils: Trace amounts of cutting fluids or forming oils remaining on the surface of parts.

- Binding Agents: Materials used in powder metallurgy or metal injection molding (MIM) that are designed to burn away during the process, leaving residue.

- Volatile Elements: The materials being processed can release certain elements at high temperatures (a process known as "outgassing"), which then deposit on cooler surfaces inside the furnace.

The Impact of Contamination

If not removed, these accumulated deposits will vaporize during subsequent heating cycles. They can then redeposit onto the new, clean batch of parts.

This can lead to severe quality control issues, such as surface discoloration, compromised structural integrity, poor brazing or welding joints, and a failure to meet strict industry specifications (e.g., in aerospace or medical applications).

How a Burnout Cycle Works

The burnout cycle is a straightforward but essential process designed to reverse this accumulation of contaminants.

Elevating the Temperature

The fundamental principle is to run the furnace hotter than its normal operating temperature. A common guideline is to set the burnout temperature approximately 50°C (122°F) higher than the hottest process you typically run.

This elevated temperature ensures that any contaminants clinging to the furnace walls, insulation, and fixtures are fully vaporized, turning them from a solid deposit into a gas.

Managing the Atmosphere

The cycle can be run under a deep vacuum or, more effectively, with a partial pressure of an inert gas like argon or nitrogen.

Using a partial pressure creates a "sweeping" action. The slow, controlled flow of inert gas helps carry the vaporized contaminants out of the hot zone and towards the vacuum pumps, improving the efficiency of the cleaning process.

Pumping Out Contaminants

The furnace's vacuum pumping system is the final piece of the puzzle. It actively draws the vaporized contaminants and any sweep gas out of the chamber, permanently removing them from the system. This leaves the interior of the furnace clean and ready for the next production run.

Understanding the Trade-offs

While essential, a burnout cycle is not without its costs and considerations. It represents a balancing act between cleanliness and operational efficiency.

Cycle Frequency vs. Productivity

A burnout cycle is non-productive time. The furnace is running, consuming energy, and undergoing thermal stress, but it is not producing parts. The key is to determine the right frequency. Running it too often wastes time and energy; not running it often enough risks scrapping expensive parts due to contamination.

Stress on Furnace Components

Running the furnace at temperatures above its normal processing range places additional thermal stress on heating elements, insulation, and the hot zone structure. This is a necessary part of maintenance, but it does contribute to the wear and tear of these components over their lifespan.

Process-Specific Needs

The "dirtiness" of your process dictates the need for a burnout. A furnace used for sintering parts with heavy binders will require much more frequent and aggressive burnout cycles than a furnace used for simple annealing of very clean parts.

How to Apply This to Your Process

Your approach to burnout cycles should be dictated by your specific parts, processes, and quality requirements.

- If your primary focus is high-purity applications (aerospace, medical): Run preventative burnout cycles on a frequent, fixed schedule to guarantee part cleanliness and eliminate any risk of contamination.

- If your primary focus is high-volume sintering (MIM, powder metals): Integrate aggressive burnout cycles as a mandatory part of your regular maintenance protocol to manage the heavy load of binder residue.

- If your primary focus is general heat treating of clean parts: Monitor parts for the first signs of discoloration or surface contamination and perform a burnout cycle reactively, as needed.

Ultimately, mastering the burnout cycle is key to leveraging the full potential of your vacuum furnace and achieving consistently flawless results.

Summary Table:

| Burnout Cycle Aspect | Key Takeaway |

|---|---|

| Purpose | A maintenance cycle to clean the furnace chamber, not a production process for parts. |

| Process | Runs hotter than normal cycles (typically +50°C) to vaporize and remove accumulated contaminants. |

| Impact | Prevents cross-contamination between batches, ensuring part quality and surface integrity. |

| Considerations | Balances furnace cleanliness with non-productive time and thermal stress on components. |

Achieve Flawless Results with a Furnace Built for Purity

Is contamination compromising your high-value heat treating processes? The right furnace design is the first step to ensuring a clean, reliable environment.

KINTEK's advanced high-temperature furnaces are engineered for excellence in critical applications. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with vacuum and atmosphere furnace solutions that support stringent cleanliness protocols. Our product line, including Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Let us help you eliminate contamination risks and achieve consistent, high-purity results.

Contact KINTEK today to discuss how our solutions can be tailored to your specific needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today