At its core, vacuum heat treatment is the process of heating and cooling metals or alloys within a high-vacuum environment. By removing air and other gases from a sealed furnace chamber, this method prevents unwanted chemical reactions, such as oxidation and decarburization, that would otherwise occur at elevated temperatures. The result is a component with superior surface quality and highly predictable material properties.

The true value of vacuum heat treatment is not simply the absence of air, but the exceptional level of control it provides. This control allows for the precise manipulation of a material's microstructure, yielding clean, bright, and high-performance parts that are unattainable with conventional atmospheric methods.

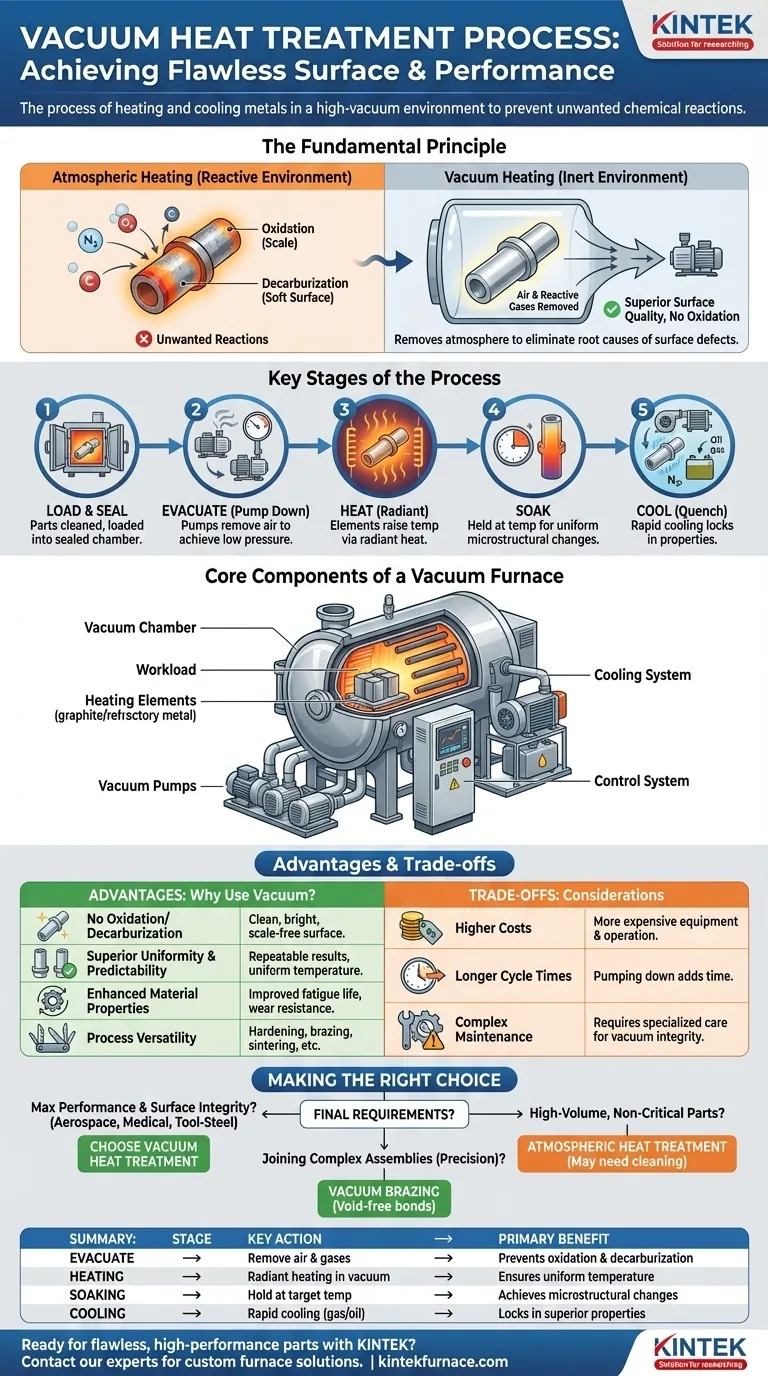

How the Vacuum Process Works

To understand the benefits of vacuum heat treatment, it's essential to first grasp its operational principles and the key stages involved. The entire process is designed around one goal: creating a chemically inert environment.

The Fundamental Principle: Removing the Atmosphere

The air around us contains approximately 78% nitrogen, 21% oxygen, and trace amounts of other gases. At high temperatures, these elements readily react with the surface of hot metal.

Oxygen causes oxidation (scaling), and for steels, carbon in the atmosphere can lead to unintended carburization, while an absence of it can cause decarburization (the loss of carbon from the surface), which softens the material. By pumping these reactive gases out of the furnace, we eliminate the root cause of these surface defects.

The Key Stages of the Process

A typical vacuum heat treatment cycle follows a precise sequence:

- Loading & Sealing: Parts are cleaned and loaded into the furnace, which is then hermetically sealed.

- Evacuation (Pump Down): A series of vacuum pumps removes air from the chamber to achieve the required low pressure.

- Heating: Electrical heating elements raise the temperature of the workload to a specific setpoint. Heat is transferred primarily through radiation in the vacuum.

- Soaking: The material is held at this temperature for a predetermined time to ensure the entire part reaches a uniform temperature and the desired microstructural changes occur.

- Cooling (Quenching): The part is cooled rapidly to lock in the desired properties. This can be done by backfilling the chamber with a high-pressure inert gas (like nitrogen or argon) or, in some furnaces, by quenching in a vacuum-compatible oil.

Core Components of a Vacuum Furnace

Several critical systems work in concert to manage this process with high precision:

- Vacuum Chamber: A robust, sealed vessel that contains the workload and can withstand both high temperatures and extreme pressure differentials.

- Heating Elements: Typically made of graphite or refractory metals, these elements radiate heat to the parts without the need for convection.

- Vacuum Pumps: A multi-stage system, often including a roughing pump and a diffusion or booster pump, is used to efficiently create and maintain the high vacuum.

- Cooling System: A powerful gas blower and heat exchanger for rapid gas quenching or an integrated oil tank for oil quenching.

- Control System: A sophisticated computer system that automates and monitors every stage of the cycle, from pressure levels to temperature ramp rates and cooling profiles.

The Advantages of a Vacuum Environment

Using a vacuum is more complex than heating in open air, but the benefits justify the investment for critical applications.

No Oxidation or Decarburization

This is the primary advantage. Parts emerge from the furnace with a clean, bright, scale-free surface, often eliminating the need for post-treatment cleaning processes like sandblasting or chemical pickling.

Superior Uniformity and Predictability

Radiant heating in a vacuum provides extremely uniform temperature distribution across the entire workload. This, combined with the lack of atmospheric interference, ensures that results are highly repeatable from one batch to the next.

Enhanced Material Properties

The clean processing environment prevents surface contamination, leading to improved fatigue life and wear resistance. Processes like vacuum carburizing can be controlled with extreme precision, creating a hard, wear-resistant case with a tough core.

Process Versatility

A single vacuum furnace can perform a wide range of processes, including hardening, annealing, tempering, brazing, degassing, and sintering, making it a highly flexible asset in a modern heat treatment facility.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution for every application. Objectivity requires acknowledging its limitations.

Higher Equipment and Operational Costs

Vacuum furnaces are significantly more complex and expensive to purchase and operate than their atmospheric counterparts. The need for robust vacuum chambers, pumps, and sophisticated control systems drives up the initial investment.

Longer Cycle Times

The process of pumping the chamber down to a deep vacuum can add considerable time to the overall cycle. For simple, high-volume parts where surface finish is not critical, atmospheric furnaces can offer higher throughput.

Increased Maintenance Complexity

Maintaining vacuum integrity is paramount. Seals, pumps, and internal furnace components require specialized and diligent maintenance to prevent leaks and ensure consistent performance.

Making the Right Choice for Your Goal

The decision to use vacuum heat treatment should be driven by the final requirements of the component.

- If your primary focus is maximum performance and surface integrity: Vacuum treatment is the definitive choice for critical aerospace, medical, or tool-steel components where oxidation or decarburization is unacceptable.

- If your primary focus is joining complex assemblies with precision: Vacuum brazing is an essential process that prevents joint contamination and ensures strong, void-free bonds.

- If your primary focus is high-volume, non-critical parts: Traditional atmospheric heat treatment may be more economical, provided that subsequent surface cleaning operations are acceptable.

By understanding these principles, you can select the precise thermal process that guarantees the required integrity and performance of your final product.

Summary Table:

| Stage | Key Action | Primary Benefit |

|---|---|---|

| Evacuation | Remove air and reactive gases | Prevents oxidation and decarburization |

| Heating | Radiant heating in a vacuum | Ensures uniform temperature distribution |

| Soaking | Hold at target temperature | Achieves desired microstructural changes |

| Cooling/Quenching | Rapid cooling with inert gas or oil | Locks in superior material properties |

Ready to achieve flawless, high-performance parts with precision vacuum heat treatment?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Whether your application requires a Muffle, Tube, Rotary, Vacuum & Atmosphere Furnace, or a specialized CVD/PECVD System, our deep customization capabilities ensure your process delivers unmatched surface integrity and material performance.

Contact our experts today to discuss how our vacuum furnaces can solve your most critical thermal processing challenges.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion