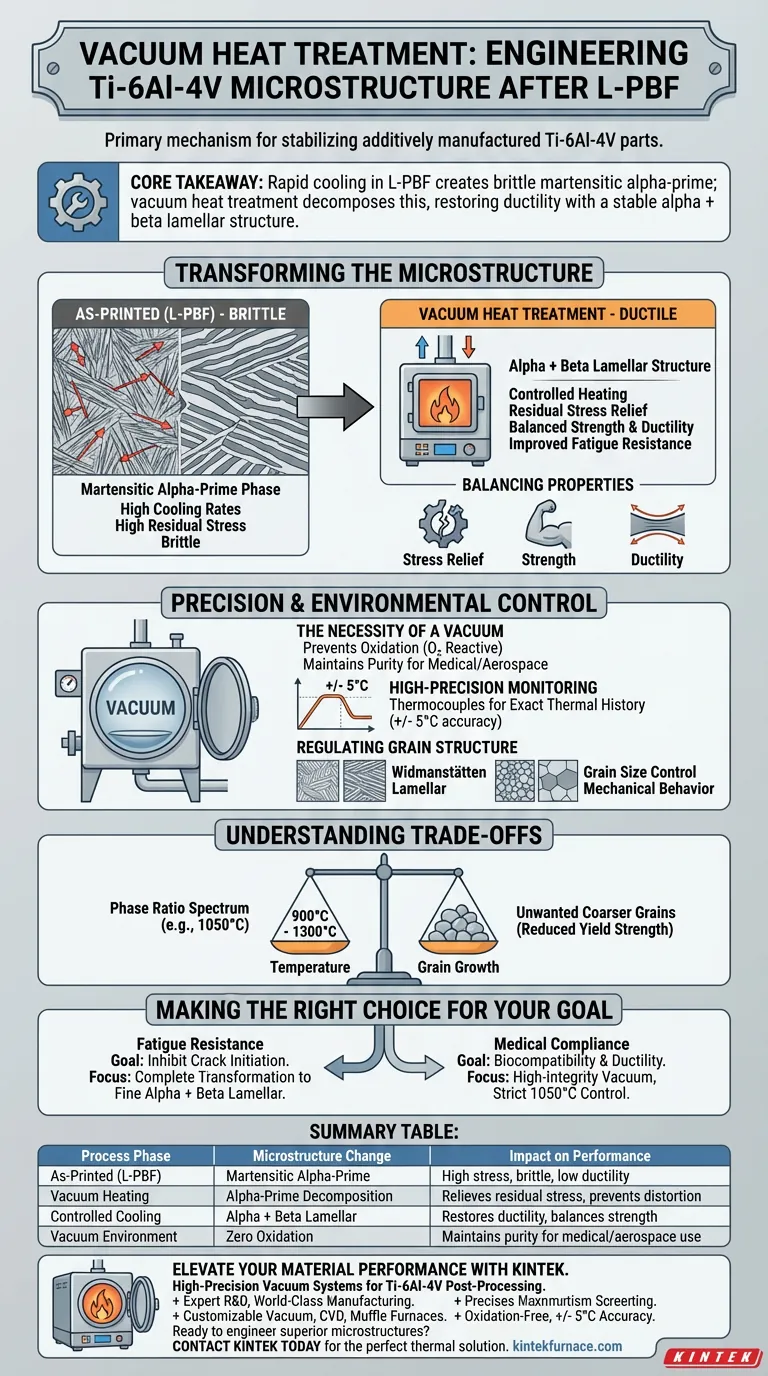

A vacuum heat treatment furnace is the primary mechanism for stabilizing the microstructure of additively manufactured Ti-6Al-4V parts. It functions by subjecting the component to controlled heating cycles in an oxidation-free environment, effectively transforming the brittle, as-printed martensitic alpha-prime phase into a ductile, stable alpha + beta lamellar structure.

Core Takeaway The rapid cooling inherent to Laser Powder Bed Fusion (L-PBF) creates highly stressed, brittle parts; vacuum heat treatment is essential to decompose this unstable microstructure into a balanced alpha + beta phase, thereby restoring ductility and improving fatigue resistance.

Transforming the Microstructure

Eliminating the Brittle Phase

The L-PBF process involves extremely high cooling rates, which naturally results in a brittle martensitic alpha-prime phase.

The primary role of the vacuum furnace is to facilitate the decomposition of this unstable phase. Through controlled heating, the microstructure transforms into a stable alpha + beta lamellar structure.

Relieving Residual Stress

The layer-by-layer nature of 3D printing introduces significant internal tension.

The heat treatment cycles effectively eliminate these residual stresses caused by the manufacturing process. This prevents distortion and premature failure during service.

Balancing Mechanical Properties

Optimizing the microstructure is not just about removing brittleness; it is about tuning performance.

By adjusting the phase component ratios and sizes, the process balances strength and ductility. This structural optimization specifically enhances the material's resistance to fatigue crack initiation.

Precision and Environmental Control

The Necessity of a Vacuum

Titanium alloys are highly reactive to oxygen at elevated temperatures.

A vacuum environment is critical to prevent the oxidation of the titanium alloy during treatment. This ensures the material remains pure and meets rigorous standards, such as those required for medical implants.

Regulating Grain Structure

The specific temperature profile directly influences the final grain morphology.

Precise control determines the formation of specific structures, such as Widmanstätten lamellar structures. It also regulates grain size, which dictates the final mechanical behavior of the part.

High-Precision Monitoring

Achieving the correct microstructure requires adhering to a strict temperature curve.

Advanced furnaces use thermocouples in direct contact with the mold to achieve accuracy up to +/- 5°C. This ensures the part is exposed to the exact thermal history required for the desired phase transformation.

Understanding the Trade-offs

Temperature vs. Grain Growth

While high temperatures are necessary for phase transformation, they must be carefully selected (typically between 900°C and 1300°C).

Excessive temperatures or prolonged exposure can lead to unwanted grain growth. Coarser grains may reduce yield strength, even as ductility improves.

Complexity of Phase Ratios

The transition from alpha-prime to alpha + beta is not binary; it is a spectrum.

The precise temperature chosen (e.g., 1,050°C) directly determines the ratio of alpha to beta phases. A slight deviation in process parameters can result in a ratio that fails to meet specific mechanical requirements.

Making the Right Choice for Your Goal

To maximize the performance of your Ti-6Al-4V parts, align your heat treatment strategy with your specific application requirements.

- If your primary focus is Fatigue Resistance: Prioritize a cycle that ensures the complete transformation of the alpha-prime phase into a fine alpha + beta lamellar structure to inhibit crack initiation.

- If your primary focus is Medical Compliance: Ensure your furnace maintains a high-integrity vacuum to prevent oxidation and strictly controls temperatures (around 1,050°C) to meet biocompatibility and ductility standards.

Ultimately, the vacuum furnace is not just a stress-relief tool, but a precision instrument for engineering the fundamental microstructure of your material.

Summary Table:

| Process Phase | Microstructure Change | Impact on Performance |

|---|---|---|

| As-Printed (L-PBF) | Martensitic Alpha-Prime | High stress, brittle, low ductility |

| Vacuum Heating | Alpha-Prime Decomposition | Relieves residual stress, prevents distortion |

| Controlled Cooling | Alpha + Beta Lamellar | Restores ductility, balances strength |

| Vacuum Environment | Zero Oxidation | Maintains purity for medical/aerospace use |

Elevate Your Material Performance with KINTEK

Maximize the mechanical integrity of your 3D-printed titanium components with KINTEK’s high-precision vacuum systems. Backed by expert R&D and world-class manufacturing, we provide customizable Vacuum, CVD, and Muffle furnaces designed to meet the rigorous demands of Ti-6Al-4V post-processing. Our systems ensure oxidation-free environments and temperature accuracy of +/- 5°C, delivering the exact phase transformation your application requires.

Ready to engineer superior microstructures? Contact KINTEK today to find the perfect thermal solution for your lab.

Visual Guide

References

- Zongchen Li, Christian Affolter. High-Cycle Fatigue Performance of Laser Powder Bed Fusion Ti-6Al-4V Alloy with Inherent Internal Defects: A Critical Literature Review. DOI: 10.3390/met14090972

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is vacuum brazing considered a clean process? Achieve Oxide-Free, Flux-Free Metal Joining

- Why are gas-based reduction shaft furnaces preferred for DRI? Maximize Efficiency with Regional Resources

- What materials are used in vacuum brazing? Join Reactive & Dissimilar Metals for High-Integrity Assemblies

- How does graphite's chemical resistance benefit vacuum furnace processes? Achieve High-Purity, Contamination-Free Results

- What are the disadvantages of graphite furnace? High Cost, Slow Speed, and Complexity

- What is a crucible furnace and what are its main components? Discover Its Key Parts and Uses

- How do multi-chamber designs improve energy efficiency? Cut Costs with Continuous Thermal Processing

- Why is argon preferred over nitrogen in certain applications? Ensure Purity in High-Temp Processes