At its core, a multi-chamber furnace improves energy efficiency by eliminating the massive energy waste of reheating the entire system for each new batch. Instead of a single chamber cycling through heating and cooling, a multi-chamber design maintains separate, dedicated zones at stable operating temperatures, allowing workpieces to move sequentially through the process. This transforms the operation from a stop-and-start batch model to a continuous or semi-continuous flow, using energy to treat the product, not to repeatedly heat the furnace itself.

The fundamental advantage of a multi-chamber design is thermal stability. By dedicating chambers to specific temperature stages, the system avoids the immense energy loss inherent in the full heating and cooling cycles of a single-chamber furnace, drastically lowering energy consumption per part produced.

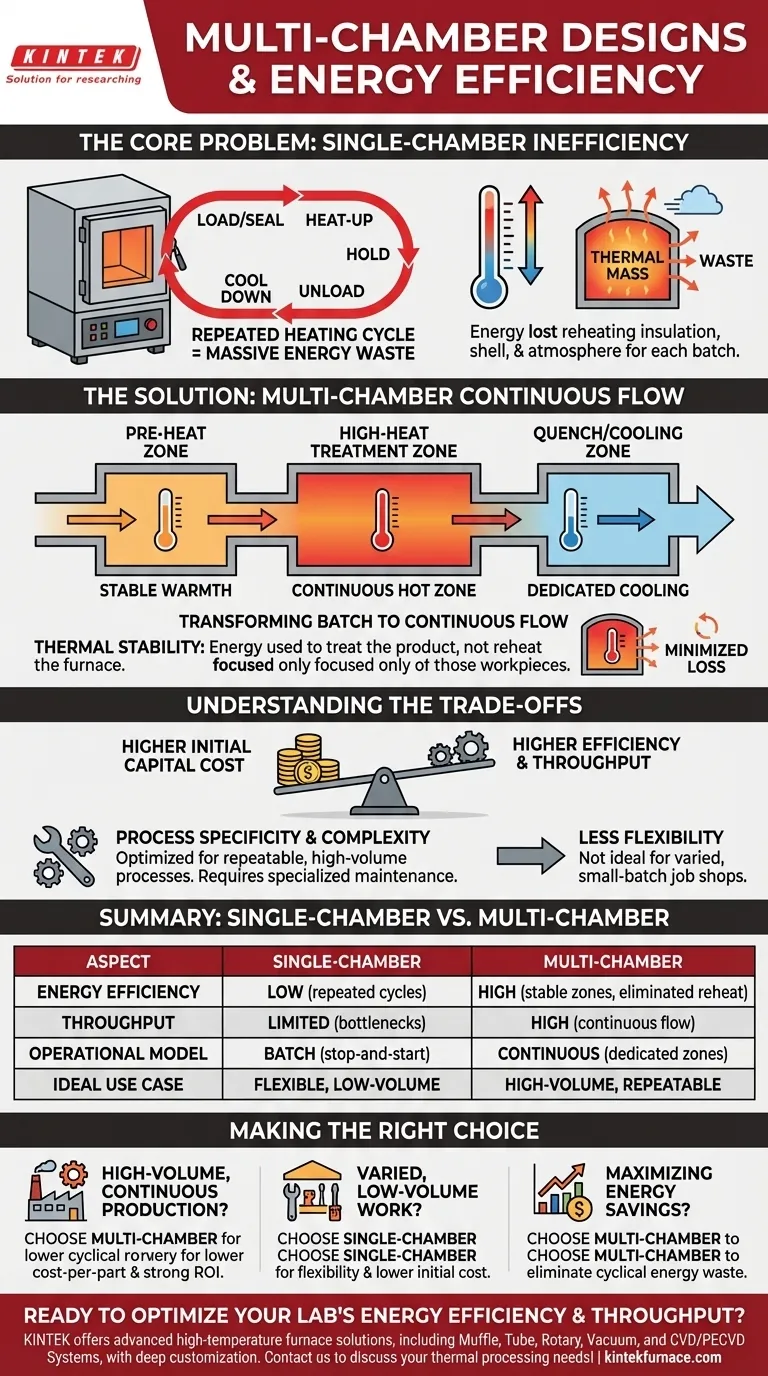

The Core Problem: Energy Waste in Single-Chamber Furnaces

To understand the efficiency of a multi-chamber system, we must first analyze the inefficiency of its single-chamber counterpart.

The Batch Processing Cycle

A traditional single-chamber furnace operates in a distinct cycle: load parts, seal the door, heat to temperature, hold (soak), and then cool down before unloading. For the next batch, this entire reheating cycle must begin again from a significantly lower temperature.

Thermal Mass and Wasted Energy

The energy consumed during heat-up does not just go into the workpiece. A massive amount is absorbed by the furnace's insulation, steel shell, and internal atmosphere—its thermal mass. In a single-chamber design, much of this stored thermal energy is lost to the surrounding environment as the furnace cools between batches, representing a significant and recurring waste.

Impact on Throughput

This constant cycling of heating and cooling dictates the furnace's total processing time. The non-productive time spent waiting for the furnace to reach temperature or cool down for safe unloading directly limits the number of batches you can run, creating a bottleneck for overall throughput.

How Multi-Chamber Designs Solve the Problem

A multi-chamber furnace is not just a bigger box; it's a fundamentally different approach to thermal processing that directly targets the inefficiencies of batch cycling.

The Principle of Continuous Flow

Think of a single-chamber furnace as an oven you preheat for every single dish you cook. A multi-chamber furnace is more like a manufacturing assembly line, where each station is always on and ready for its specific task. Workpieces move from one dedicated thermal zone to the next.

Dedicated, Thermally Stable Zones

A typical multi-chamber system might have a pre-heat chamber, a high-heat treatment chamber, and an integrated quench or cooling chamber. Each of these zones is kept at or near its operational temperature continuously. The high-heat chamber stays hot, and the quench chamber stays cool.

Minimizing Reheating Losses

Because the primary heating chamber remains at temperature, energy is only needed to heat the new workpiece and to compensate for minor heat loss when doors open briefly to transfer parts. This avoids the enormous energy expenditure of reheating the furnace's entire thermal mass from a low temperature for every cycle. This is the primary source of energy savings.

Understanding the Trade-offs and Considerations

While highly efficient, a multi-chamber design is not universally superior. The choice depends entirely on your operational needs.

Higher Initial Capital Cost

Multi-chamber systems are more complex, involving internal transfer mechanisms, multiple doors, and sophisticated control systems. This results in a significantly higher initial capital cost compared to a simpler single-chamber furnace.

Process Specificity vs. Flexibility

These furnaces are typically optimized for a specific, repeatable, high-volume process. They offer less flexibility for a job shop that handles a wide variety of part sizes, processes, and small, one-off batches.

Maintenance and Complexity

More chambers, doors, and automation mean more components that require maintenance. The mechanical transfer systems, seals between chambers, and complex control logic add layers of complexity that must be managed.

Making the Right Choice for Your Operation

Choosing between a single and multi-chamber furnace is a strategic decision that must align with your production goals and operational realities.

- If your primary focus is high-volume, continuous production: The superior energy efficiency and throughput of a multi-chamber furnace will deliver a lower cost-per-part and a strong return on investment.

- If your primary focus is process flexibility for varied, low-volume work: The lower initial cost and operational simplicity of a single-chamber furnace make it the more practical and economical choice.

- If your primary focus is maximizing energy savings for a consistent workload: The multi-chamber design is the undisputed winner, as its entire architecture is built to eliminate the cyclical energy waste found in batch processing.

Ultimately, the most energy-efficient furnace is the one that is correctly matched to your specific production demands.

Summary Table:

| Aspect | Single-Chamber Furnace | Multi-Chamber Furnace |

|---|---|---|

| Energy Efficiency | Low due to repeated heating/cooling cycles | High by eliminating reheating of thermal mass |

| Throughput | Limited by non-productive cooling/heating times | High with continuous or semi-continuous flow |

| Operational Model | Batch processing with stop-and-start cycles | Continuous flow with dedicated thermal zones |

| Ideal Use Case | Flexible, low-volume, varied processes | High-volume, consistent, repeatable processes |

| Initial Cost | Lower capital investment | Higher due to complexity and automation |

Ready to optimize your lab's energy efficiency and throughput? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on high-volume production or specialized processes, our multi-chamber designs can drastically reduce energy waste and boost productivity. Contact us today to discuss how we can enhance your thermal processing operations!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials