In short, vacuum brazing is considered a clean process because it takes place in a controlled vacuum environment. By removing the atmosphere, specifically oxygen, the process prevents the formation of oxides on the metal surfaces as they are heated. This elimination of oxidation means that chemical cleaning agents, known as fluxes, are not required, resulting in a joint that is free from residue and contamination.

The core reason vacuum brazing is exceptionally clean is that it prevents contamination from ever forming, rather than relying on chemical agents to remove it. This inherent protection results in stronger, purer joints and finished parts that are often ready for use without post-processing.

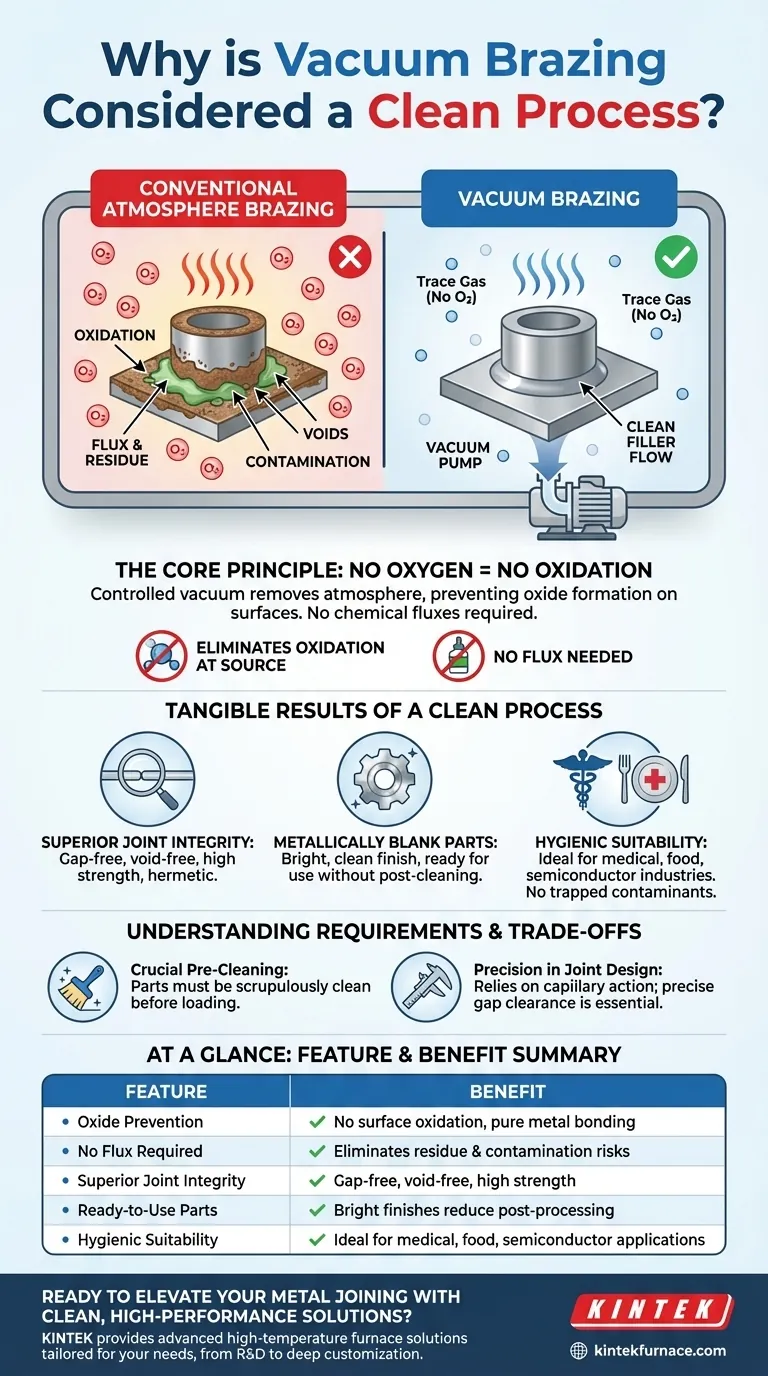

The Core Principle: How Vacuum Creates Cleanliness

To understand why vacuum brazing is so effective, it's essential to look at how the vacuum fundamentally changes the joining environment. At the high temperatures required for brazing, metals are highly reactive.

Eliminating Oxidation at the Source

In a normal atmosphere, heating metal causes it to rapidly react with oxygen, forming a layer of oxides on the surface. These oxide layers act as a barrier, preventing the filler metal from properly wetting and bonding with the parent materials.

A high-vacuum furnace removes the vast majority of atmospheric gases, including oxygen. By creating an environment with exceptionally low pressure, there are simply not enough oxygen molecules present to create oxides, even at temperatures exceeding 1100°C.

Removing the Need for Flux

In conventional brazing methods (like torch or induction brazing in open air), a chemical flux is required. Flux is an aggressive agent applied to the joint to dissolve existing oxides and prevent new ones from forming during heating.

The problem is that flux can become trapped within the joint, causing voids or future corrosion points. It also leaves behind a glassy residue that must be thoroughly cleaned off after brazing. Since a vacuum prevents oxides naturally, flux is completely unnecessary in vacuum brazing, eliminating these risks entirely.

The Tangible Results of a Clean Process

This flux-free, oxide-free environment produces tangible benefits that define the quality of the final product. The cleanliness is not just aesthetic; it is integral to the part's performance.

Superior Joint Integrity

The absence of flux and oxides allows the molten brazing alloy to flow unimpeded into the joint via capillary action. This results in gap-free, void-free joints with exceptional strength and hermetic sealing.

The process also offers excellent temperature uniformity and slow, controlled cooling cycles. This reduces residual stress across the assembly, preserving the metal's structural integrity and preventing distortion or cracking.

Metallically Blank and Ready-to-Use Parts

Parts emerging from a vacuum furnace are bright, shiny, and metallically blank. There is no flux residue to clean or discoloration from oxidation.

In many cases, the components are ready for immediate use or the next stage of assembly, saving significant time and cost associated with post-braze cleaning operations.

Suitability for Hygienic Applications

The combination of a clean finish and gap-free joints makes vacuum brazing the preferred method for components in the medical, food, and semiconductor industries. The smooth, non-porous joints leave no room for bacteria or contaminants to become trapped, ensuring a hygienic and easily sterilizable surface.

Understanding the Trade-offs and Requirements

While the results are pristine, achieving them requires meticulous preparation and process control. The "cleanliness" of the output is directly dependent on the cleanliness of the input.

The Critical Role of Pre-Cleaning

Vacuum brazing maintains cleanliness; it does not create it. The components must be scrupulously cleaned before being assembled and placed in the furnace. Any oils, greases, or other surface contaminants will vaporize in the vacuum and can contaminate the entire furnace and the parts within it.

Precision in Joint Design

The process relies on capillary action to pull the filler metal into the joint. This requires a very precise and consistent gap, or joint clearance, typically between 0.025 mm and 0.125 mm. Deviations from this can lead to incomplete joint fill or a weak bond.

Strict Process Control and Equipment

Successful vacuum brazing requires high-quality furnaces capable of maintaining a deep vacuum at high temperatures. The entire thermal cycle—from heating, to a brief soak at brazing temperature, to slow cooling—must be precisely controlled to ensure the metallurgical properties of the final assembly are met.

Making the Right Choice for Your Goal

Deciding if vacuum brazing is right for your project depends on your primary objective.

- If your primary focus is high-purity or hygienic applications: Vacuum brazing is the ideal choice, as it produces residue-free and gap-free joints required for medical or food-grade standards.

- If your primary focus is maximum joint strength and reliability: The void-free, low-stress joints created in a vacuum are superior for critical applications like aerospace and defense.

- If your primary focus is high-volume production efficiency: Vacuum brazing can be highly efficient, as processes like hardening and age-treating can often be combined into a single furnace cycle.

Ultimately, vacuum brazing provides a level of quality and cleanliness that is integral to the process itself, making it a powerful tool for manufacturing high-performance components.

Summary Table:

| Feature | Benefit |

|---|---|

| Oxide Prevention | No surface oxidation, ensuring pure metal bonding |

| No Flux Required | Eliminates residue and contamination risks |

| Superior Joint Integrity | Gap-free, void-free joints with high strength |

| Ready-to-Use Parts | Bright, shiny finishes reduce post-processing |

| Hygienic Suitability | Ideal for medical, food, and semiconductor applications |

Ready to elevate your metal joining with clean, high-performance solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is enhanced by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in aerospace, medical, or other high-purity industries, our vacuum brazing expertise ensures superior results. Contact us today to discuss how we can help you achieve flawless, efficient brazing processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity