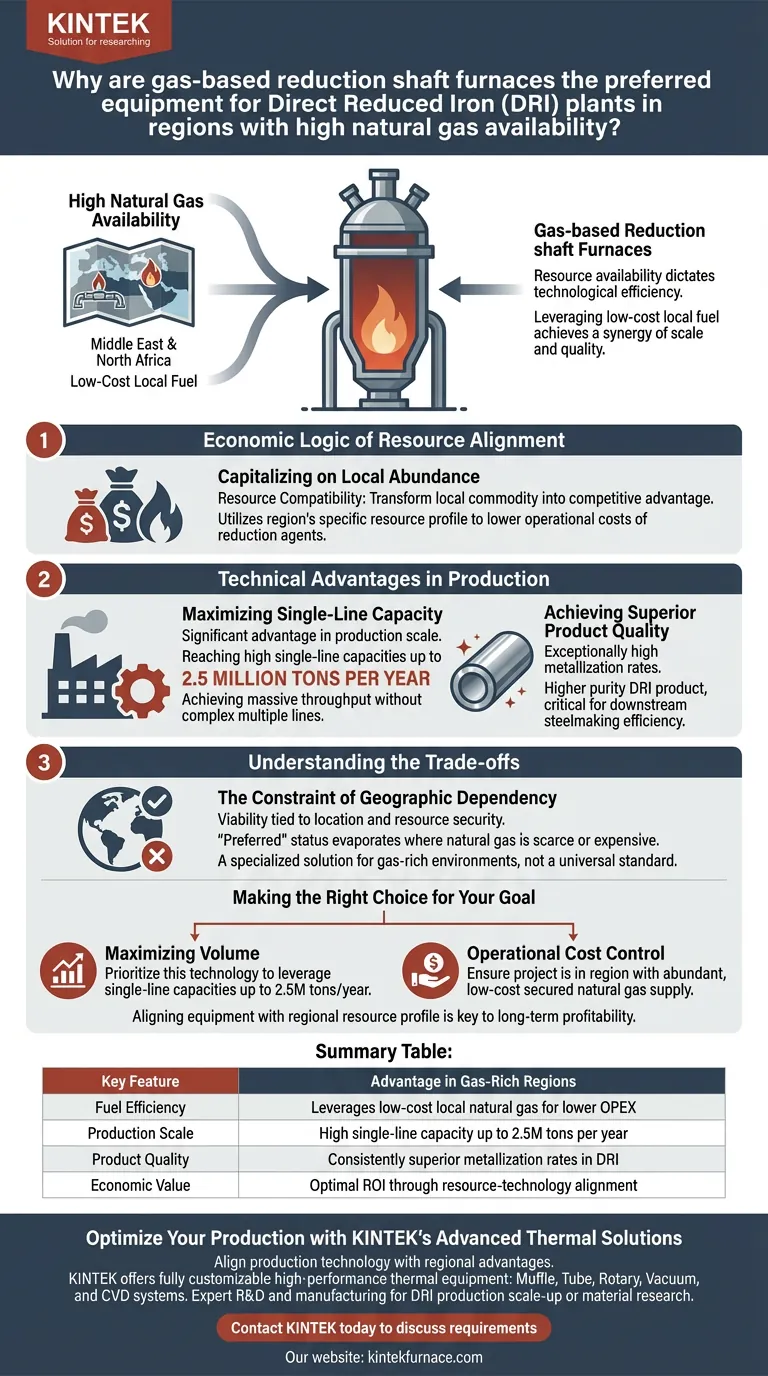

Resource availability dictates technological efficiency. In regions possessing abundant and cost-effective natural gas, such as the Middle East and North Africa, gas-based reduction shaft furnaces are the preferred technology because they align directly with the local resource profile to maximize economic and operational efficiency.

By leveraging low-cost local fuel, these furnaces achieve a synergy of scale and quality, enabling high single-line production capacities while ensuring superior metallization in the final Direct Reduced Iron (DRI) product.

The Economic Logic of Resource Alignment

Capitalizing on Local Abundance

The primary driver for adopting gas-based shaft furnaces is resource compatibility.

In areas where natural gas is plentiful, these systems transform a local commodity into a competitive advantage.

By utilizing the region's specific resource profile, operators can significantly lower the operational costs associated with reduction agents.

Technical Advantages in Production

Maximizing Single-Line Capacity

Beyond fuel costs, these furnaces offer significant advantages in production scale.

They are capable of reaching high single-line capacities, with output reaching up to 2.5 million tons per year.

This allows plants to achieve massive throughput without the complexity of managing multiple smaller processing lines.

Achieving Superior Product Quality

Quantity does not come at the expense of quality in these systems.

Gas-based reduction shaft furnaces are noted for ensuring exceptionally high metallization rates.

This results in a higher purity DRI product, which is critical for downstream steelmaking efficiency.

Understanding the Trade-offs

The Constraint of Geographic Dependency

While highly efficient, the viability of this technology is strictly tied to location and resource security.

The "preferred" status of these furnaces evaporates in regions where natural gas is scarce or expensive.

Investors must recognize that this technology is a specialized solution for gas-rich environments, not a universal standard for all geographies.

Making the Right Choice for Your Goal

To determine if this technology fits your strategic roadmap, consider your primary constraints:

- If your primary focus is maximizing volume: Prioritize this technology to leverage single-line capacities that can reach 2.5 million tons per year.

- If your primary focus is operational cost control: Ensure your project is located in a region where the natural gas supply is both abundant and secured at a low cost.

Aligning your equipment choice with your regional resource profile is the single most important factor in securing long-term plant profitability.

Summary Table:

| Key Feature | Advantage in Gas-Rich Regions |

|---|---|

| Fuel Efficiency | Leverages low-cost local natural gas for lower OPEX |

| Production Scale | High single-line capacity up to 2.5M tons per year |

| Product Quality | Consistently superior metallization rates in DRI |

| Economic Value | Optimal ROI through resource-technology alignment |

Optimize Your Production with KINTEK’s Advanced Thermal Solutions

Are you looking to align your production technology with regional resource advantages? At KINTEK, we understand that precision and efficiency are paramount. Backed by expert R&D and manufacturing, we offer a comprehensive range of high-performance thermal equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to meet your unique industrial or laboratory needs.

Whether you are scaling up DRI production or conducting specialized material research, our engineering team is ready to provide the technical edge you need. Contact KINTEK today to discuss your specific requirements and discover how our tailored high-temperature solutions can drive your project's success.

Visual Guide

References

- Tetiana Golub, Molchanov Lavr. ESTABLISHMENT OF THERMODYNAMICAL AND PHYSICO-CHEMICAL PREREQUISITES FOR DIRECT OBTAINING IRON BY THERMOLISIS OF OXIDES. DOI: 10.31319/2519-2884.47.2025.1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What core function does a furnace perform in pine cone activated carbon production? Master Controlled Pyrolysis

- What is the function of introducing 150 Pa of argon gas into a furnace during the vacuum refining of AM60 magnesium alloy?

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the leak rate for a vacuum furnace? Ensuring Process Integrity and Purity

- Why is a non-consumable vacuum arc furnace typically selected for preparing AlFeCoCrNiCu high-entropy alloy substrates?

- How does dew point monitoring influence the process control of sintering furnaces in MIM? Ensure Peak Material Quality

- What is the primary function of a vacuum drying oven in the synthesis of ZIF-8 precursors? Protect Your MOF Integrity

- What is the working principle of a vacuum furnace? Achieve High-Purity Heat Treatment for Sensitive Materials