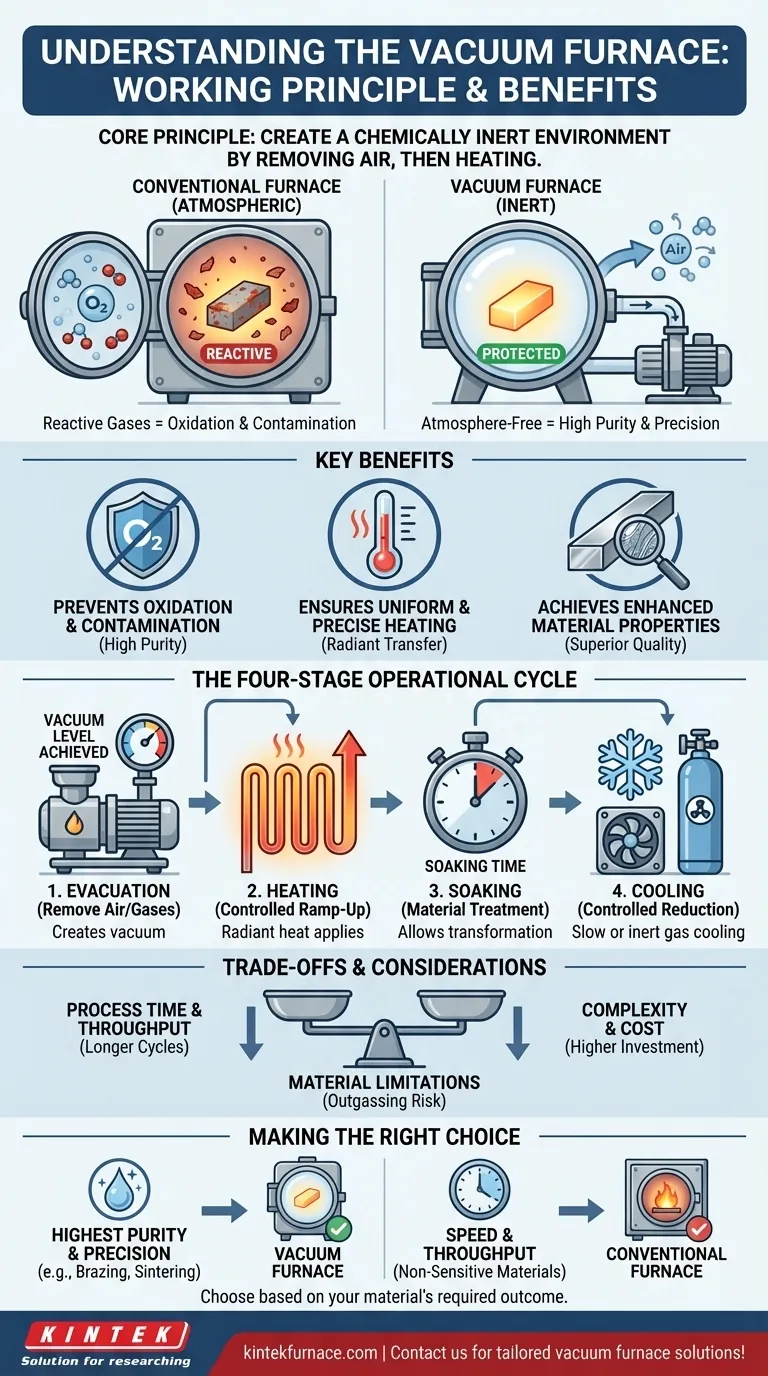

At its core, a vacuum furnace works by first removing the air and other gases from a sealed chamber to create a vacuum. It then heats the material inside that controlled, atmosphere-free environment using powerful heating elements. This simple two-step principle—evacuate then heat—is what allows it to achieve results impossible with a conventional furnace.

The fundamental purpose of a vacuum furnace is not just to generate heat, but to create a chemically inert environment. By removing the atmosphere, it prevents unwanted reactions like oxidation and contamination, enabling the high-purity processing of sensitive materials.

The Core Principle: Heating in an Atmosphere-Free Environment

Understanding a vacuum furnace requires shifting your perspective. The vacuum isn't a side effect; it is the central feature that defines the entire process and its superior outcomes.

Preventing Oxidation and Contamination

At high temperatures, most metals and many ceramics readily react with oxygen and other gases present in the air. This causes oxidation (rusting or scaling) and other chemical reactions that degrade the material's surface and structural integrity.

By pumping out the air, a vacuum furnace eliminates these reactive gases. This allows materials to be heated to extreme temperatures without compromising their surface finish or chemical purity.

Ensuring Uniform and Precise Heating

A vacuum environment primarily relies on radiant heat transfer, where heat radiates directly from the heating elements to the material. This method promotes highly uniform heating across the entire part, minimizing hot spots and internal stresses.

Combined with sophisticated temperature control systems, this allows for extremely precise and repeatable heating cycles, which are critical for processes like brazing and annealing.

Achieving Enhanced Material Properties

The pristine environment inside a vacuum furnace leads to finished products with superior qualities. By preventing contamination and ensuring uniform heat treatment, the process enhances the material's final physical and mechanical properties, such as strength, hardness, and durability.

The Four-Stage Operational Cycle

Every vacuum furnace process follows a distinct, carefully controlled sequence. While specifics vary, the operation can be broken down into four fundamental stages.

Stage 1: Evacuation

The cycle begins by loading the material into the furnace and sealing the chamber door. The vacuum pumping system is then activated to remove air and any other residual gases. This process continues until a specific, predetermined vacuum level is achieved.

Stage 2: Heating

Once the target vacuum is reached, the heating elements are energized. The temperature is raised according to a programmed profile specific to the material and the desired treatment. This ramp-up is carefully controlled to ensure stability.

Stage 3: Soaking (Treatment)

The material is held at the target temperature for a specific duration, a process known as soaking. This allows the heat to fully penetrate the material and for the desired metallurgical transformation, such as sintering or brazing, to occur completely.

Stage 4: Cooling

After the soaking stage is complete, the heating elements are turned off, and the material is cooled. Cooling can be accomplished slowly by letting the furnace radiate heat away, or rapidly by introducing a high-purity inert gas like nitrogen or argon to speed up the process. This cooling phase is often just as critical as the heating cycle.

Understanding the Trade-offs and Considerations

While incredibly powerful, vacuum furnace technology involves clear trade-offs that are important to understand for proper application.

Process Time and Throughput

Vacuum furnace cycles are inherently longer than atmospheric furnace cycles. The time required for evacuation and controlled cooling adds significant duration, which can impact overall throughput.

Equipment Complexity and Cost

These are sophisticated systems involving sealed chambers, high-performance vacuum pumps, and advanced control systems. This complexity results in higher initial investment and maintenance costs compared to conventional furnaces.

Material Limitations (Outgassing)

Some materials can release trapped gases or volatile elements when heated under vacuum, a phenomenon called outgassing. This can compromise the vacuum level and potentially contaminate the furnace interior or the material itself, requiring careful material selection and process design.

Making the Right Choice for Your Goal

Selecting the right heat treatment technology depends entirely on the required outcome for your material.

- If your primary focus is achieving the highest material purity and preventing any surface oxidation: A vacuum furnace is essential, as it eliminates the atmospheric reactants that cause these issues.

- If your primary focus is process speed and high throughput for non-sensitive materials: A conventional atmospheric furnace may be a more cost-effective and faster solution.

- If your primary focus is precise, repeatable control over complex heating and cooling cycles: The sophisticated control systems and stable environment of a vacuum furnace provide unmatched consistency.

Ultimately, mastering the principles of a vacuum furnace empowers you to leverage a perfectly controlled environment to produce materials of exceptional quality.

Summary Table:

| Stage | Description | Key Function |

|---|---|---|

| Evacuation | Remove air and gases from the chamber | Creates a vacuum to eliminate reactive gases |

| Heating | Apply heat using elements in vacuum | Enables precise temperature control via radiant transfer |

| Soaking | Hold at target temperature | Allows complete material transformation (e.g., sintering) |

| Cooling | Reduce temperature slowly or with inert gas | Ensures controlled cooling for enhanced properties |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your material purity and achieve superior results with our tailored vacuum furnace solutions!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control