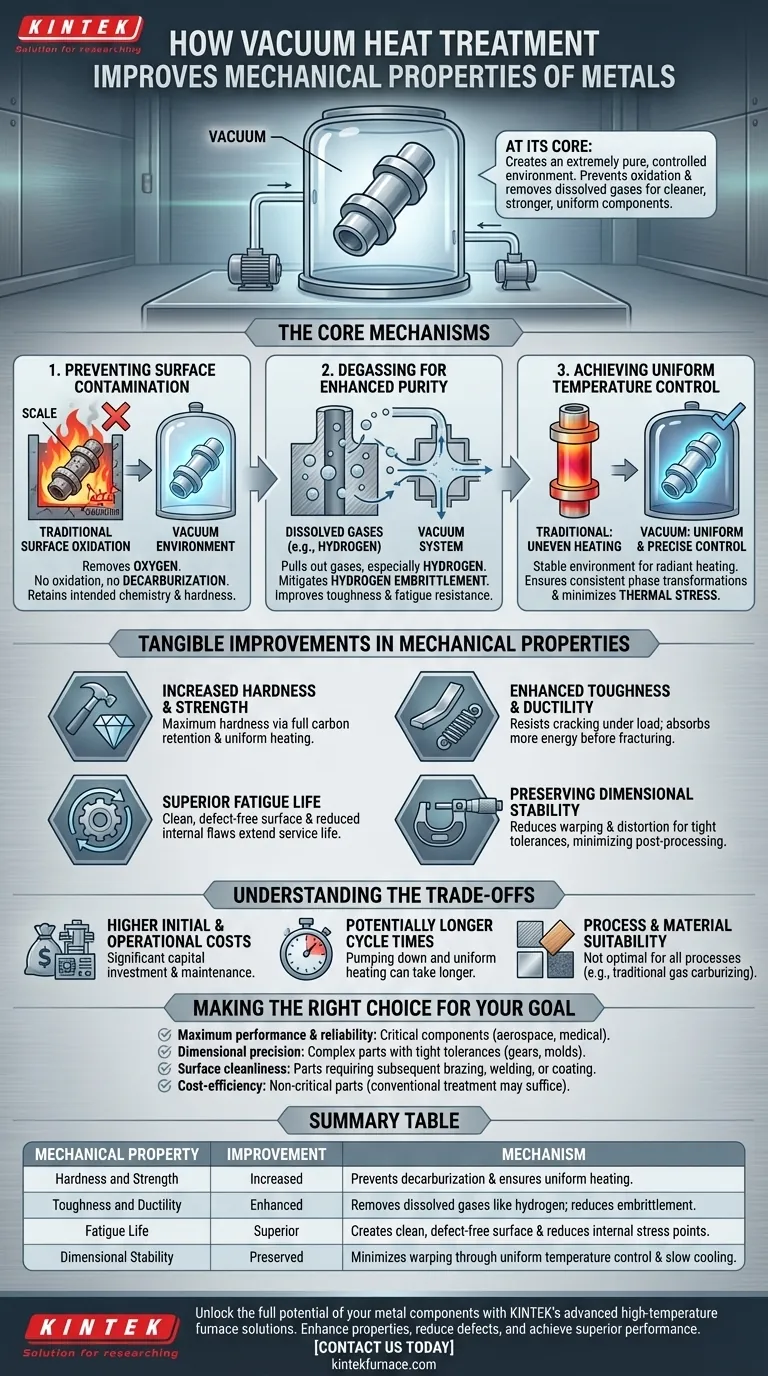

At its core, vacuum heat treatment improves the mechanical properties of metals by creating an extremely pure, controlled environment. This process prevents harmful surface reactions like oxidation and removes detrimental dissolved gases from within the metal, resulting in a cleaner, stronger, and more uniform final component with enhanced toughness, strength, and dimensional stability.

The fundamental advantage of vacuum heat treatment is control. By removing atmospheric contaminants, the process allows for precise thermal manipulation that enhances a metal’s inherent potential without introducing the flaws common in conventional atmospheric treatments.

The Core Mechanisms of Vacuum Heat Treatment

To understand the benefits, we must first look at the underlying mechanisms that make this process so effective. The vacuum itself is not what strengthens the metal; it is the ideal environment it creates for the heat treatment to work perfectly.

Preventing Surface Contamination

In a traditional furnace, the atmosphere's oxygen reacts with the hot metal surface, forming a brittle, flaky layer of oxide known as scale.

This scale can compromise surface finish and hardness. A vacuum environment, by definition, removes the oxygen, completely preventing oxidation and decarburization (the loss of carbon from the surface of steel), ensuring the material's surface retains its intended chemistry and hardness.

Degassing for Enhanced Purity

Metals often contain dissolved gases, with hydrogen being the most harmful. These trapped gases create internal stress and points of weakness.

Vacuum heat treatment effectively pulls these gases out of the metal. This reduction in internal gases, particularly hydrogen, mitigates a phenomenon called hydrogen embrittlement, directly improving the material's toughness and resistance to fatigue.

Achieving Uniform Temperature Control

A vacuum provides a stable environment for radiant heating, allowing for exceptionally uniform and precise temperature control across the entire part.

This uniformity ensures that the entire component undergoes the desired phase transformations at the same time, leading to a consistent microstructure and predictable mechanical properties. It also minimizes thermal stress, which is a primary cause of distortion.

Tangible Improvements in Mechanical Properties

The controlled mechanisms of vacuum treatment translate directly into measurable improvements in the performance and lifespan of metal components.

Increased Hardness and Strength

By preventing surface decarburization, the part retains its full carbon content, allowing it to achieve maximum hardness and strength during quenching. The uniform heating also ensures this hardness is consistent across the entire geometry.

Enhanced Toughness and Ductility

Removing dissolved hydrogen and preventing the formation of a brittle oxide layer makes the metal significantly less prone to cracking under load. This results in superior toughness and plasticity, allowing the part to absorb more energy before fracturing.

Superior Fatigue Life

Mechanical failure often begins at microscopic imperfections on the surface or within the material. Vacuum treatment produces an exceptionally clean and defect-free surface, while degassing reduces internal initiation points for cracks.

This cleanliness dramatically increases the component's fatigue strength, extending its service life under cyclic loading, which is critical for parts like bearings, gears, and shafts.

Preserving Dimensional Stability

The combination of slow, uniform heating and controlled cooling in a vacuum environment drastically reduces warping and distortion. This dimensional stability is critical for high-precision components with tight tolerances, often minimizing or eliminating the need for costly post-treatment grinding or machining.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution. Objectivity requires acknowledging its limitations.

Higher Initial and Operational Costs

Vacuum furnaces are complex machines that represent a significant capital investment. They are more expensive to purchase, operate, and maintain compared to conventional atmospheric furnaces.

Potentially Longer Cycle Times

The process of pumping down the chamber to a deep vacuum and ensuring uniform heating can take longer than simply placing a part in a standard furnace. For high-volume, low-margin parts, this can impact throughput.

Process and Material Suitability

While versatile, vacuum treatment is not optimal for every metallurgical process. Certain case-hardening techniques, like traditional gas carburizing, are more complex to perform in a vacuum and may be better suited to atmospheric methods.

Making the Right Choice for Your Goal

Selecting the right heat treatment method depends entirely on the component's performance requirements and economic constraints.

- If your primary focus is maximum performance and reliability: Vacuum treatment is the superior choice for critical components in aerospace, medical, or high-performance tooling where failure is not an option.

- If your primary focus is dimensional precision: Choose vacuum treatment for complex parts with tight tolerances, such as gears and molds, to minimize distortion and reduce post-processing costs.

- If your primary focus is surface cleanliness: For parts requiring subsequent brazing, welding, or coating, the pristine surface from vacuum treatment ensures superior bonding and finish.

- If your primary focus is cost-efficiency for non-critical parts: Conventional atmospheric treatment often provides sufficient properties for less demanding applications at a lower cost.

By understanding these principles, you can leverage the right thermal process to unlock the full engineering potential of your chosen material.

Summary Table:

| Mechanical Property | Improvement | Mechanism |

|---|---|---|

| Hardness and Strength | Increased | Prevents decarburization and ensures uniform heating for consistent phase transformations. |

| Toughness and Ductility | Enhanced | Removes dissolved gases like hydrogen to reduce embrittlement and improve energy absorption. |

| Fatigue Life | Superior | Creates a clean, defect-free surface and reduces internal stress points for longer service life. |

| Dimensional Stability | Preserved | Minimizes warping and distortion through uniform temperature control and slow cooling. |

Unlock the full potential of your metal components with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Enhance mechanical properties, reduce defects, and achieve superior performance—contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics