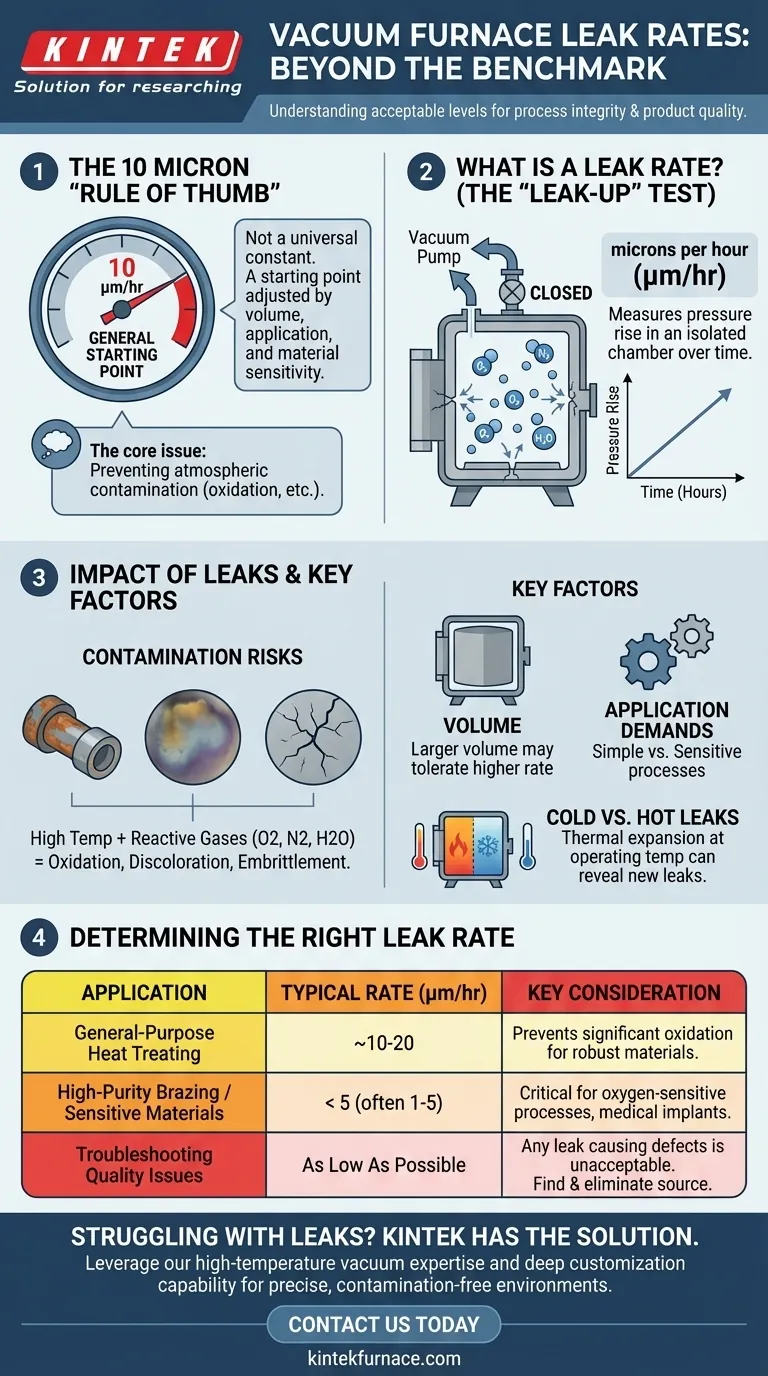

As a general benchmark, an acceptable leak rate for a standard vacuum furnace is often cited as 10 microns per hour. However, this figure is not a universal constant; it is a starting point that must be adjusted based on the furnace's volume, its intended application, and the sensitivity of the materials being processed.

The core issue isn't meeting a generic number, but understanding how atmospheric leaks impact your specific process. A "good" leak rate is one that is low enough to prevent unwanted reactions, like oxidation, ensuring the integrity and quality of your final product.

What is a Leak Rate and Why Does it Matter?

A leak rate quantifies the integrity of your vacuum chamber. It is measured by evacuating the furnace, isolating it from the vacuum pumps, and measuring the rate at which the pressure rises over time due to gas entering the chamber from the outside.

The "Leak-Up" Test Explained

This measurement is formally known as a "leak-up rate" test. The unit, microns per hour (µm/hr), describes how many microns of pressure the chamber gains each hour when sealed. A higher number indicates a larger leak.

The Impact of Leaks on Your Process

Even a small leak allows atmospheric gases—primarily nitrogen, oxygen, and water vapor—to enter the furnace. At the high temperatures of a furnace cycle, these reactive gases can cause significant problems.

This contamination can lead to oxidation, discoloration, and embrittlement of the parts you are treating. For sensitive processes like brazing or medical implant manufacturing, even a minuscule leak can compromise the metallurgical bond or surface quality, leading to product failure.

Factors That Determine an "Acceptable" Leak Rate

The 10 microns/hour rule of thumb is a useful starting point, but a true expert evaluates furnace integrity based on several key factors.

The Role of Chamber Volume

A small leak will cause the pressure to rise much faster in a small-volume chamber than in a very large one. Therefore, larger furnaces can often tolerate a numerically higher leak rate while maintaining the same low partial pressure of contaminants.

The Demands of the Application

The process itself is the most important factor. A simple hardening process for a robust steel tool may be perfectly successful with a leak rate of 10-20 microns/hour.

Conversely, brazing oxygen-sensitive alloys or heat-treating titanium for medical implants requires an extremely pure environment. For these applications, a leak rate of 1-5 microns/hour or even lower may be necessary to prevent any contamination.

Understanding the Trade-offs

Achieving and maintaining a low leak rate is a balancing act. It is crucial to distinguish between what is ideal and what is practical.

The Cost of Chasing Perfection

Finding and fixing leaks can be a time-consuming and expensive maintenance task. Striving for a leak rate far below what your process requires can lead to diminishing returns, increasing downtime and costs for no tangible benefit to your product quality.

Cold vs. Hot Leak Rates

A furnace that shows an acceptable leak rate when cold and at room temperature may develop leaks when hot. Thermal expansion can cause flanges, seals, and other components to shift, opening up new leak paths. A "hot leak-up test," performed at operating temperature, gives a much more realistic assessment of the furnace's performance during an actual cycle.

Determining the Right Leak Rate for Your Furnace

Your goal is not to hit an arbitrary number, but to ensure the vacuum environment is clean enough for your specific work. Use your process requirements as the ultimate guide.

- If your primary focus is general-purpose heat treating: The 10 microns/hour benchmark is a reasonable target to ensure consistent, baseline quality.

- If your primary focus is high-purity brazing or processing sensitive materials: You must aim for a much lower rate, typically below 5 microns/hour, and verify results with destructive testing or surface analysis.

- If you are troubleshooting part discoloration or quality issues: Your current leak rate is too high, regardless of the number. Your immediate goal is to locate and eliminate the source of the contamination.

Ultimately, the best leak rate is the one that consistently produces quality parts for your specific application.

Summary Table:

| Application | Typical Acceptable Leak Rate (µm/hr) | Key Consideration |

|---|---|---|

| General-Purpose Heat Treating | ~10-20 | Prevents significant oxidation for robust materials. |

| High-Purity Brazing / Sensitive Materials | < 5 (often 1-5) | Critical for preventing contamination in oxygen-sensitive processes. |

| Troubleshooting Quality Issues | As low as possible | Any measurable leak rate causing discoloration or failure is unacceptable. |

Struggling with furnace leaks affecting your product quality? KINTEK's expertise in high-temperature vacuum solutions is your key to achieving the precise, contamination-free environment your sensitive processes demand. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced furnaces—including Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures your equipment is tailored to meet your unique leak rate and purity requirements. Contact us today (#ContactForm) to discuss how we can enhance your process integrity and final product quality.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision