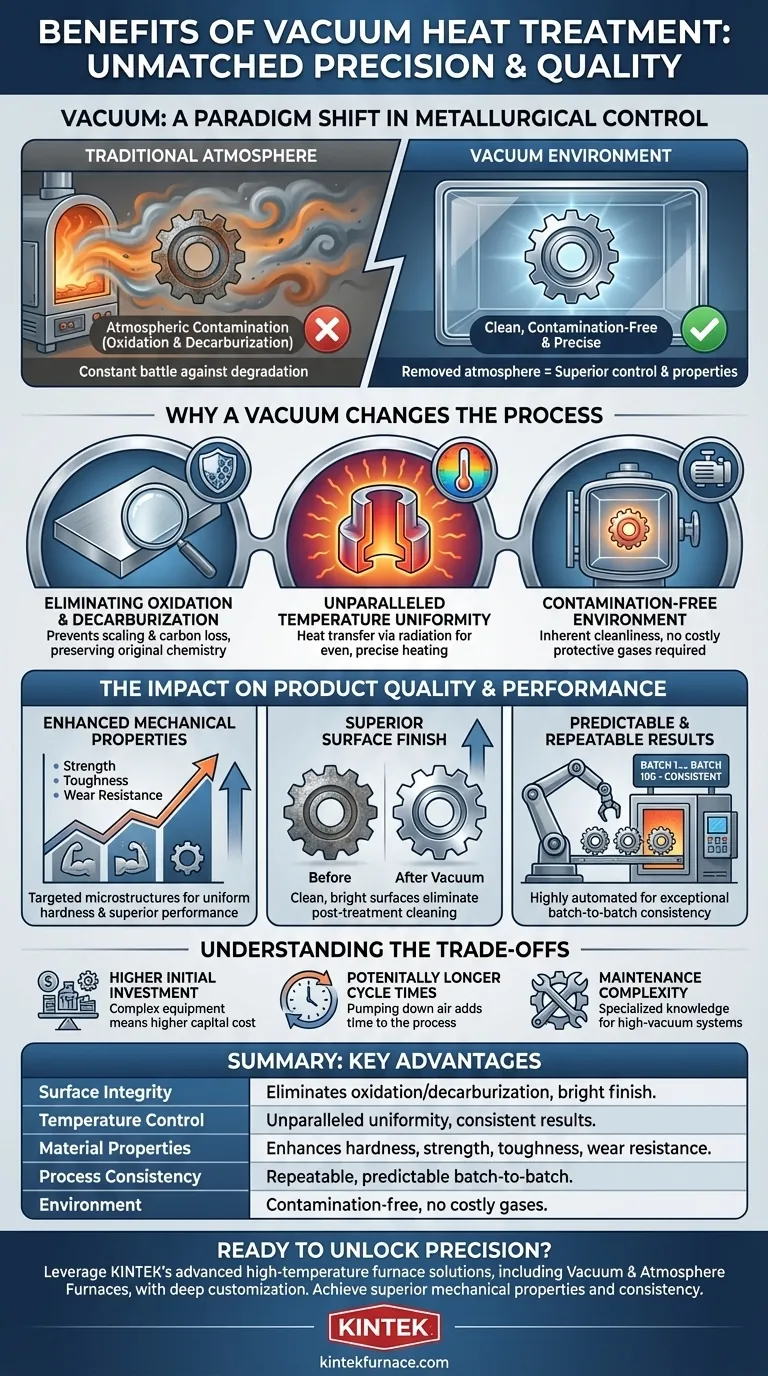

At its core, vacuum heat treatment provides unmatched control over the metallurgical process. By removing the atmosphere from the furnace, this method prevents unwanted chemical reactions like oxidation and decarburization. This results in a clean, bright surface finish and allows for extremely precise temperature control, leading to superior and highly repeatable material properties.

Traditional heat treatment is a constant battle against atmospheric contamination. Vacuum heat treatment fundamentally changes the objective by removing the atmosphere altogether, transforming the process from one of protection to one of precision.

Why a Vacuum Changes the Process

Conducting heat treatment in a vacuum isn't just a minor adjustment; it is a paradigm shift that provides a level of control that is impossible to achieve in a conventional atmosphere.

Eliminating Oxidation and Decarburization

In a traditional furnace, the oxygen and other reactive gases in the air attack the hot surface of a metal part. This causes oxidation (scaling) and decarburization (the loss of carbon from the steel's surface), which degrade both the appearance and the mechanical properties.

A vacuum environment is virtually free of these reactive gases. By removing the air, you remove the cause of these reactions, preserving the part’s original surface chemistry and integrity.

Achieving Unparalleled Temperature Uniformity

In a vacuum, heat transfer occurs primarily through radiation. This allows for exceptionally uniform heating, as all surfaces of the part are heated evenly without interference from convection currents found in atmosphere furnaces.

This precise and uniform temperature control is critical for ensuring that the entire part, including complex geometries, achieves the target temperature and undergoes the desired metallurgical transformation consistently.

Guaranteeing a Contamination-Free Environment

Atmosphere furnaces often require the use of expensive or flammable gases like argon or hydrogen to create a protective environment and prevent oxidation.

Vacuum treatment inherently creates a clean environment without the need for these costly consumables. This not only saves money but also enhances safety by eliminating the handling of flammable gases.

The Impact on Product Quality and Performance

The control offered by vacuum processing translates directly into measurable improvements in the final product.

Enhanced Mechanical Properties

The precise control over heating and, more importantly, cooling (quenching) cycles allows for the targeted development of specific microstructures. This results in more uniform hardness, improved strength, greater toughness, and higher wear resistance.

Superior Surface Finish

Parts emerge from a vacuum furnace with a clean, bright surface, free from scale or discoloration. In many cases, this eliminates the need for post-treatment cleaning or finishing operations like sandblasting or pickling, saving time and cost.

Predictable and Repeatable Results

Modern vacuum furnaces are highly automated systems. The combination of a controlled environment and precise digital programming ensures that every cycle runs exactly the same way. This leads to exceptional batch-to-batch consistency and a dramatic reduction in rejected parts.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not a universal solution. An objective assessment requires understanding its limitations.

Higher Initial Investment

Vacuum furnaces are complex pieces of equipment with high-vacuum pumps and sophisticated control systems. This results in a significantly higher upfront capital cost compared to conventional atmosphere furnaces.

Potentially Longer Cycle Times

The need to pump the air out of the chamber before the heating cycle begins adds time to the overall process. For high-volume, low-margin parts, this can be a critical factor in throughput calculations.

Maintenance Complexity

High-vacuum systems require specialized knowledge for maintenance and repair. Seals, pumps, and sensors must be meticulously maintained to ensure the integrity of the vacuum, which can increase operational complexity.

Making the Right Choice for Your Application

Selecting the correct heat treatment method depends entirely on the technical requirements and economic realities of your project.

- If your primary focus is surface finish and part integrity: Vacuum treatment is the superior choice, as it prevents surface degradation and often eliminates the need for costly post-process cleaning.

- If your primary focus is achieving specific, high-performance mechanical properties: The unparalleled temperature uniformity and process control of vacuum heat treatment provide unmatched consistency for critical components.

- If your primary focus is minimizing upfront capital cost for simple parts: A conventional atmosphere furnace may be a more economical solution, provided you can tolerate some surface oxidation and process variability.

By understanding these core principles, you can confidently determine when vacuum heat treatment is not just an alternative, but a critical manufacturing advantage.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Surface Integrity | Eliminates oxidation and decarburization for a bright, clean finish. |

| Temperature Control | Provides unparalleled heating uniformity for consistent results. |

| Material Properties | Enhances hardness, strength, toughness, and wear resistance. |

| Process Consistency | Delivers highly repeatable, predictable outcomes batch-to-batch. |

| Environment | Creates a contamination-free setting without costly protective gases. |

Ready to unlock the precision of vacuum heat treatment for your critical components?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Whether you need to eliminate surface oxidation, achieve superior mechanical properties, or ensure batch-to-batch consistency, our experts can help you select or customize the ideal vacuum furnace for your application.

Contact our specialists today to discuss how our vacuum heat treatment solutions can enhance your product quality and manufacturing efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion