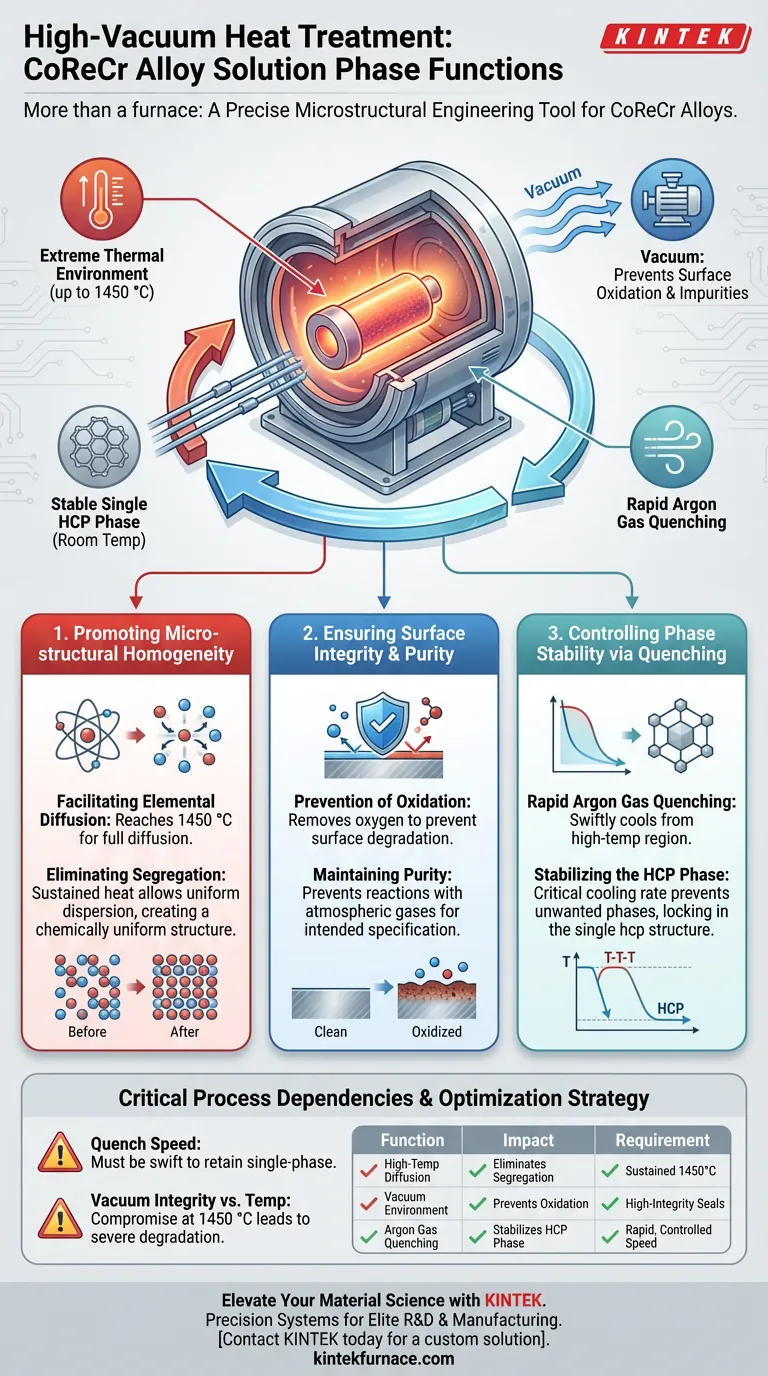

A high-vacuum heat treatment furnace serves as a precise microstructural engineering tool during the solution heat treatment of CoReCr alloys. Its primary functions are to generate extreme thermal environments (up to 1450 °C) to drive elemental diffusion, maintain a vacuum to prevent surface oxidation, and execute rapid argon gas quenching to lock in a specific crystalline structure.

Core Takeaway The furnace functions not merely as a heating element, but as a controlled atmosphere chamber that eliminates compositional segregation. Its ability to transition rapidly from high-vacuum heating to argon quenching is the critical factor in stabilizing the alloy's single hcp phase at room temperature.

Promoting Microstructural Homogeneity

Facilitating Elemental Diffusion

To achieve the desired material properties, the furnace must provide an extreme temperature environment capable of reaching 1450 °C.

At this thermal tier, the furnace provides the energy required for the full diffusion of alloying elements throughout the matrix.

Eliminating Compositional Segregation

As-cast alloys often suffer from uneven distribution of elements. The sustained high heat allows these elements to migrate and disperse evenly.

This function eliminates compositional segregation, transforming the material into a chemically uniform structure.

Ensuring Surface Integrity and Purity

Prevention of Oxidation

The "high-vacuum" aspect of the furnace is functionally critical for CoReCr alloys.

By removing oxygen from the heating chamber, the furnace ensures the alloy surface remains free from oxidation, which is a common risk at elevated temperatures.

Maintaining Material Purity

While the primary goal is oxidation prevention, the vacuum environment inherently supports overall purity.

It prevents the reaction of active elements within the alloy with atmospheric gases, ensuring the final composition matches the intended design specifications.

Controlling Phase Stability via Quenching

Rapid Argon Gas Quenching

Heating is only half the equation; the furnace’s cooling function is equally vital.

The system utilizes an argon gas quenching mechanism to rapidly cool the alloy from the high-temperature single-phase region.

Stabilizing the HCP Phase

The specific cooling rate controls the crystalline structure of the metal as it returns to room temperature.

By cooling rapidly, the furnace prevents the formation of unwanted phases, resulting in a stable single hcp (hexagonal close-packed) phase structure.

Critical Process Dependencies

The Necessity of Quench Speed

The transition from 1450 °C to room temperature must be swift and controlled.

If the furnace's argon quenching system is insufficient, the material may not retain the desired single-phase structure, compromising its stability.

Vacuum Integrity vs. Temperature

Operating at 1450 °C places immense stress on furnace components.

Any compromise in the vacuum seal at these extreme temperatures will lead to immediate and severe surface degradation, negating the benefits of the heat treatment.

Optimizing the Heat Treatment Strategy

To ensure the successful processing of CoReCr alloys, consider the following functional priorities:

- If your primary focus is Structural Homogeneity: Ensure the furnace can sustain 1450 °C long enough to fully eliminate compositional segregation through diffusion.

- If your primary focus is Surface Quality: Verify the vacuum integrity is maintained throughout the entire heating cycle to strictly prevent oxidation.

- If your primary focus is Phase Stability: Calibrate the argon gas quenching system to maximize cooling speed, ensuring the formation of the single hcp phase.

The success of CoReCr solution heat treatment relies entirely on the furnace's ability to balance extreme heat for diffusion with rapid cooling for phase stabilization.

Summary Table:

| Furnace Function | Impact on CoReCr Alloy | Critical Requirement |

|---|---|---|

| High-Temp Diffusion | Eliminates compositional segregation | Sustained heating up to 1450°C |

| Vacuum Environment | Prevents surface oxidation and impurities | High-integrity vacuum seals |

| Argon Gas Quenching | Stabilizes single hcp phase structure | Rapid, controlled cooling speed |

Elevate Your Material Science with KINTEK

Precision in CoReCr alloy processing requires equipment that can handle extreme thermal stress without compromising vacuum integrity. KINTEK provides industry-leading Vacuum, CVD, and high-temperature Muffle systems designed for elite R&D and manufacturing. Our customizable furnaces ensure your materials achieve perfect microstructural homogeneity and phase stability.

Ready to optimize your heat treatment process? Contact KINTEK today for a custom solution.

Visual Guide

References

- Torben Fiedler, Joachim Rösler. Temperature-Dependent Young’s Modulus of TaC- and TiC-Strengthened Co-Re-Based Alloys. DOI: 10.3390/met14030324

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is a high-temperature vacuum furnace required for in situ heating experiments involving Tantalum?

- How do vacuum chambers and heating systems prepare zirconium alloy samples? Achieving Precise Hydrogen Concentration

- Why is a vacuum sintering furnace recommended for high-density MgO? Achieve Near-Zero Porosity & Optical Purity

- What is the function of a vacuum drying oven in MAPbBr3@SiO2/PVDF preparation? Enhance Composite Stability & Density

- Why is a vacuum furnace used for long-term heat exposure experiments on Nb-22.5Cr-5Si alloys? Ensure Data Integrity

- What role does a high-temperature furnace play in CsPbCl3-MSN synthesis? Mastering Thermal Encapsulation

- What conditions does a vacuum furnace provide for Nb3Sn repair? Precision Heat and High Vacuum for Superconductors

- What are the key uses of vacuum annealing furnaces? Achieve Superior Material Integrity and Purity