The primary recommendation for using a vacuum sintering furnace in the final re-sintering stage of magnesium oxide (MgO) preparation is its superior ability to maximize material density. Unlike air sintering, a vacuum environment actively facilitates the removal of trapped gases and volatile impurities, preventing them from becoming locked within the crystal structure.

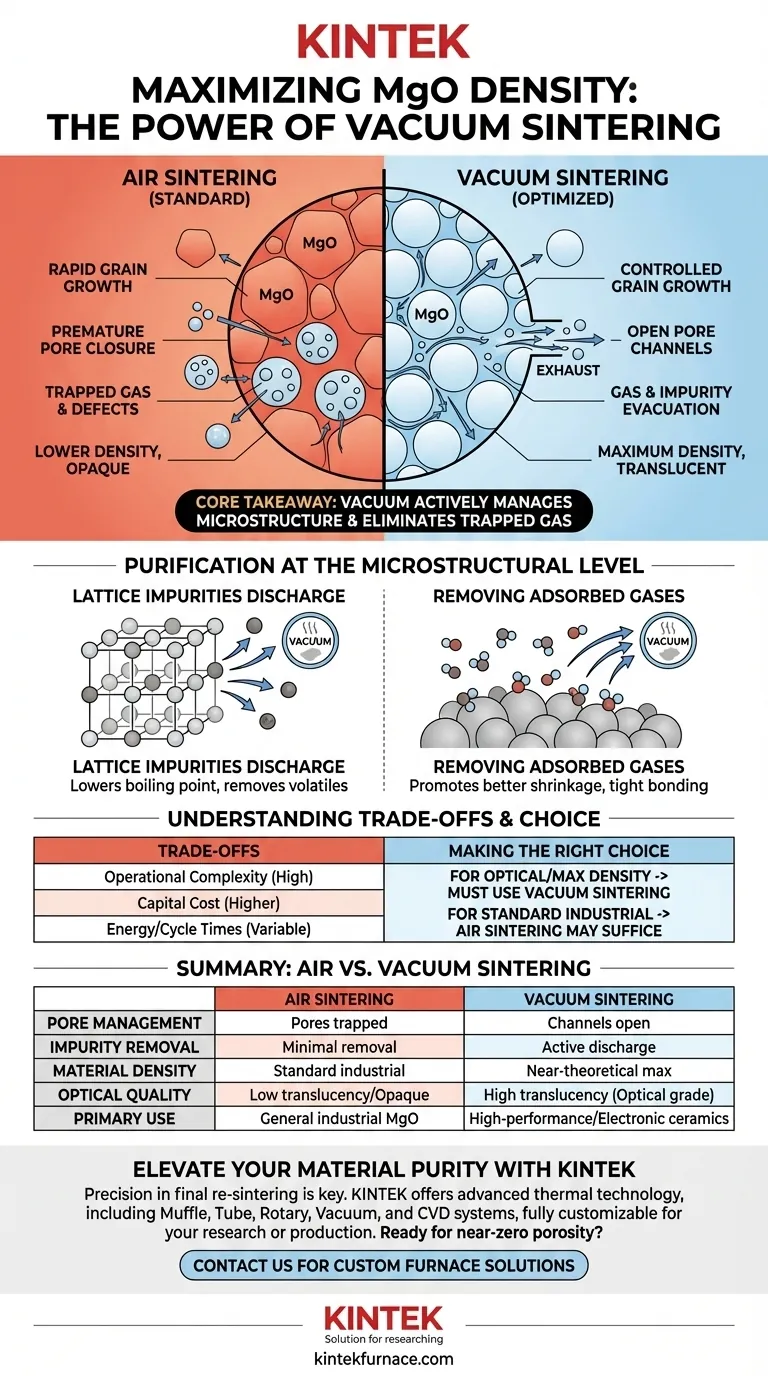

Core Takeaway Achieving high-density MgO requires more than just heat; it requires the active management of the material's microstructure. Vacuum sintering resolves the conflict between grain growth and gas evacuation, ensuring that porosity is eliminated rather than trapped, which is essential for producing high-translucency, high-density ceramics.

The Mechanics of Densification

Inhibiting Pore Closure

In standard air sintering, grains often grow rapidly and unpredictably. This "abnormal" growth can seal off the outer surfaces of the material before the interior has fully densified.

Once these pores are closed off, any remaining gas is trapped inside, creating permanent defects that lower density. Vacuum sintering effectively inhibits this premature pore closure.

Controlling Grain Growth

By maintaining a vacuum, the sintering environment moderates the energy dynamics at the grain boundaries.

This prevents the grains from growing uncontrollably fast. Slower, more controlled grain growth keeps the pore channels open longer, allowing gases to escape effectively before the material structure solidifies.

Purification at the Microstructural Level

Discharging Lattice Impurities

The brine precipitation method can leave residual volatile impurities within the crystal lattice of the magnesium oxide.

A vacuum environment lowers the boiling point of these volatiles. This allows them to be discharged thoroughly from the lattice, purifying the material far more effectively than air sintering could achieve.

Removing Adsorbed Gases

Magnesium oxide powder surfaces often hold adsorbed gases that hinder particle bonding.

The vacuum actively strips these gases away. This removal promotes better shrinkage in the later stages of sintering, allowing the particles to bond tightly and significantly increasing the final relative density.

Understanding the Trade-offs

Operational Complexity vs. Quality

While vacuum sintering yields superior density and translucency, it introduces higher operational complexity.

Maintaining a consistent vacuum requires precise equipment and seal integrity. Any leak can reintroduce oxygen or nitrogen, negating the benefits and potentially contaminating the batch.

Cost Implications

Vacuum sintering furnaces are significantly more capital-intensive than standard air kilns.

The energy consumption and cycle times may also differ. This method is specifically recommended when the end goal is high-performance or optical-grade MgO, where the cost is justified by the necessity for near-zero porosity.

Making the Right Choice for Your Goal

Depending on the final application of your magnesium oxide, the sintering method will dictate the quality of your output.

- If your primary focus is Optical Transparency or Maximum Density: You must use vacuum sintering to ensure the removal of all volatiles and the prevention of trapped pores.

- If your primary focus is Standard Industrial Grade: Air sintering may be sufficient if slight porosity or lower translucency is acceptable for the application.

Vacuum sintering is not just a heating process; it is a purification tool that ensures the structural integrity of high-density ceramics.

Summary Table:

| Feature | Air Sintering | Vacuum Sintering |

|---|---|---|

| Pore Management | Pores often trapped by fast grain growth | Channels kept open for gas evacuation |

| Impurity Removal | Minimal removal of lattice volatiles | Active discharge of volatile impurities |

| Material Density | Standard industrial density | Near-theoretical maximum density |

| Optical Quality | Low translucency/Opaque | High translucency (Optical grade) |

| Primary Use | General industrial MgO | High-performance/Electronic ceramics |

Elevate Your Material Purity with KINTEK

Precision in the final re-sintering stage is the difference between standard industrial grade and high-performance optical ceramics. KINTEK provides the advanced thermal technology required to master these complex processes.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable for your unique research or production needs. Whether you are optimizing brine precipitation or developing next-generation MgO ceramics, our vacuum systems ensure the precise atmosphere control necessary for maximum densification.

Ready to achieve near-zero porosity in your magnesium oxide production? Contact us today to find your custom furnace solution.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a vacuum oven used for drying ionogels? Preserve Structural Integrity for Precise Electron Microscopy

- Why is a vacuum drying oven required for processing ball-milled red mud-alumina powder? Essential Drying Facts

- Why are inert gases necessary in vacuum furnaces? Unlock Precision in Heat Treatment

- What are the main features and advantages of a vacuum heat treatment furnace? Achieve Superior Material Quality & Efficiency

- What are the technical advantages of using a Vacuum oven for drying Mg2Al LDH? Preserve Structural Integrity and Purity

- What are the benefits of using a vacuum drying oven for sensitive ceramic materials? Unlock Unmatched Material Purity

- What industries commonly use vacuum brazing furnaces? Essential for Aerospace, Medical, Automotive, and Electronics

- What are the applications of furnace brazing in the energy and power generation sector? Achieve Superior Joint Integrity for Critical Components