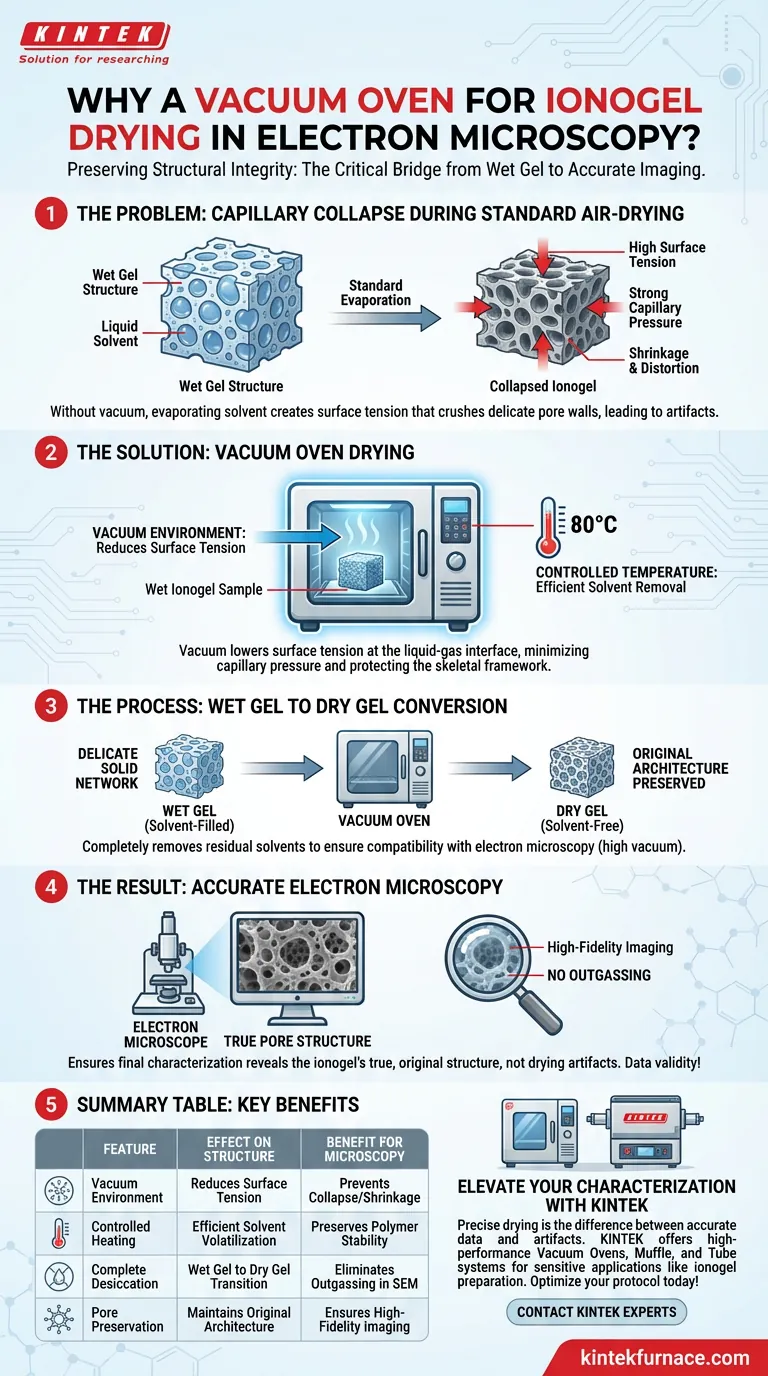

A vacuum oven serves as the critical bridge between a wet ionogel and a sample suitable for accurate electron microscopy. It is employed to completely remove residual solvents from the gel pores at controlled temperatures (e.g., 80°C), effectively converting wet gels into dry gels without destroying their internal architecture. This specific drying method is vital for preserving the material's integrity prior to imaging.

By lowering surface tension at the liquid-gas interface, vacuum drying minimizes the capillary pressure that causes structural collapse. This ensures that the final characterization reveals the ionogel's true, original pore structure rather than artifacts created by the drying process.

Preserving Structural Integrity

The Threat of Capillary Collapse

Ionogels typically consist of a delicate solid network filled with liquid solvent. During standard evaporation, the retreating liquid creates surface tension at the liquid-gas interface.

This tension generates significant capillary pressure. In a standard air-drying context, this pressure is often strong enough to crush the pore walls, leading to shrinkage and a distorted structure.

Reducing Surface Tension

The vacuum oven addresses this physical challenge by altering the environment in which evaporation occurs. Drying in a vacuum significantly reduces the surface tension exerted on the pore walls.

By mitigating these forces, the process protects the skeletal framework of the ionogel. This allows the solvent to escape without dragging the solid structure inward.

Converting Wet Gels to Dry Gels

The ultimate goal of this treatment is to transition the sample from a "wet gel" state to a "dry gel" state.

This must be done completely to ensure compatibility with electron microscopy, which typically operates under high vacuum. Any residual solvent could outgas inside the microscope, obscuring the image or damaging the equipment.

Understanding the Constraints

The Necessity of Controlled Temperature

While the vacuum aids in solvent removal, thermal energy is still required to drive the process efficiently.

The reference notes a controlled temperature of 80°C. This specific control is essential; the heat must be sufficient to volatilize the solvent but regulated to prevent thermal degradation of the polymer network.

The Standard for Accuracy

If a sample is not dried using this method, the resulting images will be scientifically misleading.

Without vacuum drying, you are likely observing a collapsed material rather than the original ionogel. Therefore, this step is not merely about preparation, but about data validity.

Making the Right Choice for Your Goal

To ensure your electron microscopy results are reliable, consider the following regarding your drying protocol:

- If your primary focus is accurate characterization: You must use vacuum drying to minimize structural collapse, ensuring the observed pores reflect the true nature of the material.

- If your primary focus is process consistency: strictly monitor the temperature (e.g., 80°C) to balance efficient solvent removal with the preservation of the gel's chemical stability.

Precise vacuum drying effectively freezes the ionogel's original architecture in place, allowing you to see the material as it truly exists.

Summary Table:

| Feature | Effect on Ionogel Structure | Benefit for Microscopy |

|---|---|---|

| Vacuum Environment | Reduces surface tension & capillary pressure | Prevents structural collapse/shrinkage |

| Controlled Heating | Efficient solvent volatilization | Preserves polymer network stability |

| Complete Desiccation | Transition from wet gel to dry gel | Eliminates outgassing in the SEM chamber |

| Pore Preservation | Maintains original internal architecture | Ensures high-fidelity, accurate imaging |

Elevate Your Materials Characterization with KINTEK

Precise drying is the difference between accurate data and structural artifacts. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Ovens, Muffle, Tube, and CVD systems tailored for sensitive laboratory applications like ionogel preparation. Whether you need customizable temperature control or superior vacuum stability, our equipment ensures your samples remain intact from the lab to the microscope.

Ready to optimize your drying protocol? Contact our experts today to find the perfect thermal solution for your research needs.

Visual Guide

References

- Yutong Shen, Simon R. Hall. Comparison of acid- and base-catalysed sol–gel synthesis for the <i>in situ</i> crystallisation of a perovskite. DOI: 10.1039/d5sm00608b

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How does the pressure environment affect the metallic thermal reduction for titanium? Master Precision Control

- How does a circulating water cooling system contribute to the stable operation of high-temp vacuum furnaces? | KINTEK

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What are the primary differences in sintering strategies for ceramic membranes? Optimize Your Thermal Processing

- What are the main components of a vacuum annealing furnace? Essential Systems for Precision Heat Treatment

- Why is a vacuum drying oven essential for the processing of battery electrode sheets? Ensure Battery Safety & Longevity

- How does a diffusion annealing furnace enhance magnet coercivity? Boost Performance with Grain Boundary Diffusion

- How do industrial-grade vacuum furnaces refine grain and relieve stress in Inconel 718? Achieve Peak Superalloy Strength