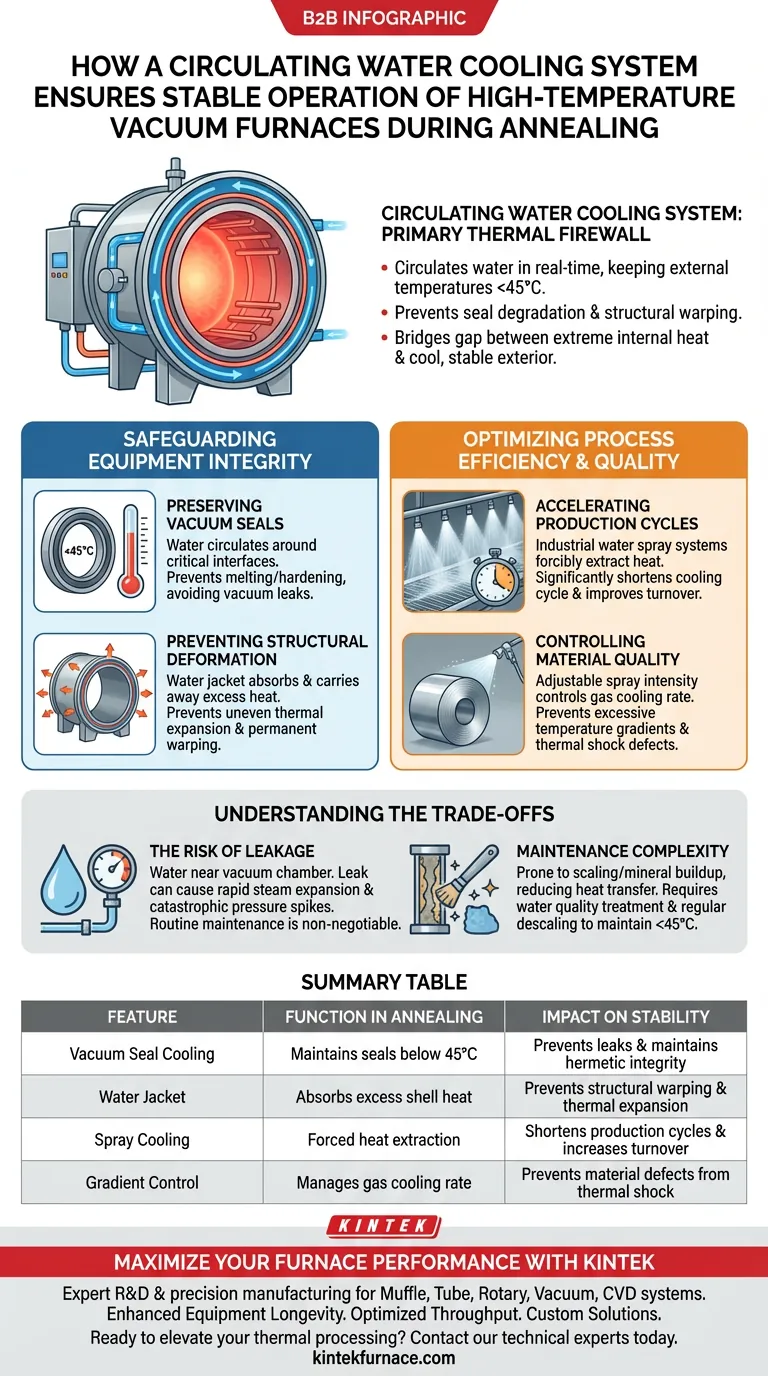

A circulating water cooling system serves as the primary thermal firewall for high-temperature vacuum furnaces. It functions by circulating water through the furnace shell and sealing interfaces in real time, ensuring that external equipment temperatures remain strictly below 45°C to prevent seal degradation and structural warping.

High-temperature annealing requires a delicate balance: generating extreme internal heat while maintaining a cool, stable exterior. The circulating water system bridges this gap, protecting the vessel's vacuum integrity and the physical properties of the treated material.

Safeguarding Equipment Integrity

The primary function of the cooling system is to protect the furnace hardware from the destructive effects of the heat it generates.

Preserving Vacuum Seals

Vacuum furnaces rely on rubber or silicone seals to maintain a hermetic environment. These materials degrade rapidly when exposed to high temperatures.

The cooling system circulates water around these critical interfaces. By keeping the temperature below 45°C, it prevents the seals from melting or hardening, thereby avoiding vacuum leaks that would compromise the entire annealing process.

Preventing Structural Deformation

During long-duration isothermal annealing, the furnace body is subjected to intense thermal stress. Without active cooling, the metal shell would expand unevenly.

The water jacket absorbs and carries away this excess heat. This prevents thermal expansion from causing permanent structural deformation, ensuring the furnace maintains its precise geometry and operational safety standards.

Optimizing Process Efficiency and Quality

Beyond protecting the hardware, advanced cooling methods—such as industrial water-cooling spray systems—actively contribute to the efficiency of the annealing cycle.

Accelerating Production Cycles

Passive air cooling is often too slow for industrial demands. Water spray systems forcibly extract heat from the outer wall of the inner cover.

This significantly increases cooling intensity. The result is a drastically shortened cooling cycle, which improves equipment turnover rates and overall plant productivity.

Controlling Material Quality

Rapid cooling must be managed carefully to avoid damaging the product. Spray intensity can be adjusted to control the cooling rate of the protective gas inside the furnace.

This precise control prevents excessive temperature gradients between the inside and outside of the material (such as steel coils). By managing this gradient, the system prevents mechanical property defects caused by thermal shock.

Understanding the Trade-offs

While essential for stability, water cooling systems introduce specific operational risks that must be managed.

The Risk of Leakage

The most critical trade-off is the introduction of water near a high-temperature vacuum chamber. A leak into the vacuum space can lead to rapid steam expansion, potentially causing catastrophic pressure spikes.

Routine maintenance of the piping and jacket integrity is non-negotiable to prevent this safety hazard.

Maintenance Complexity

Circulating water systems are prone to scaling and mineral buildup over time. This buildup insulates the pipes, reducing heat transfer efficiency.

To maintain the required <45°C shell temperature, operators must treat the water quality and perform regular descaling operations.

Ensuring Operational Success

To maximize the benefits of your cooling system, align your maintenance strategy with your specific operational goals.

- If your primary focus is Equipment Longevity: Prioritize monitoring the outlet water temperature and shell surface spots to ensure they never exceed the 45°C safety threshold.

- If your primary focus is Production Throughput: Invest in adjustable spray cooling controls to maximize heat extraction rates without compromising the metallurgical properties of your load.

The cooling system is not just an accessory; it is the fundamental component that allows extreme thermal processing to occur safely within a confined mechanical structure.

Summary Table:

| Feature | Function in Annealing | Impact on Stability |

|---|---|---|

| Vacuum Seal Cooling | Maintains seals below 45°C | Prevents leaks & maintains hermetic integrity |

| Water Jacket | Absorbs excess shell heat | Prevents structural warping & thermal expansion |

| Spray Cooling | Forced heat extraction | Shortens production cycles & increases turnover |

| Gradient Control | Manages gas cooling rate | Prevents material defects from thermal shock |

Maximize Your Furnace Performance with KINTEK

Don't let thermal stress compromise your production efficiency. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature furnaces are fully customizable to meet your unique laboratory or industrial requirements.

Our value to you:

- Enhanced Equipment Longevity: Protect your investment with advanced cooling designs.

- Optimized Throughput: Reduce cooling cycles with precision-engineered spray systems.

- Custom Solutions: Tailored configurations for specific annealing and heat treatment needs.

Ready to elevate your thermal processing? Contact our technical experts today to find the perfect solution for your lab.

Visual Guide

References

- Feng Guo. Research on the Performance of AlCrSiWN Tool Coatings for Hardened Steel Cutting. DOI: 10.62051/ijmee.v6n2.01

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a high-temperature vacuum furnace benefit vacuum heat treatment and sintering processes? Unlock Superior Material Quality

- What is vacuum sintering and its significance? Achieve Superior Material Performance

- Why is vacuum heat treatment necessary? Achieve Superior Material Purity and Performance

- What is a crucible furnace and what is it used for? A Guide to Clean Metal Melting

- How is furnace brazing used in research and development? Unlock Precision Joining for Material Innovation

- What are the advantages of vacuum furnaces? Achieve Pristine Material Processing and Control

- How does the multi-chamber design solve the heating-cooling conflict? Boost Efficiency and Throughput

- Why is precise pressure control necessary in high-temperature reaction vessels? Optimize Mesophase Pitch Synthesis