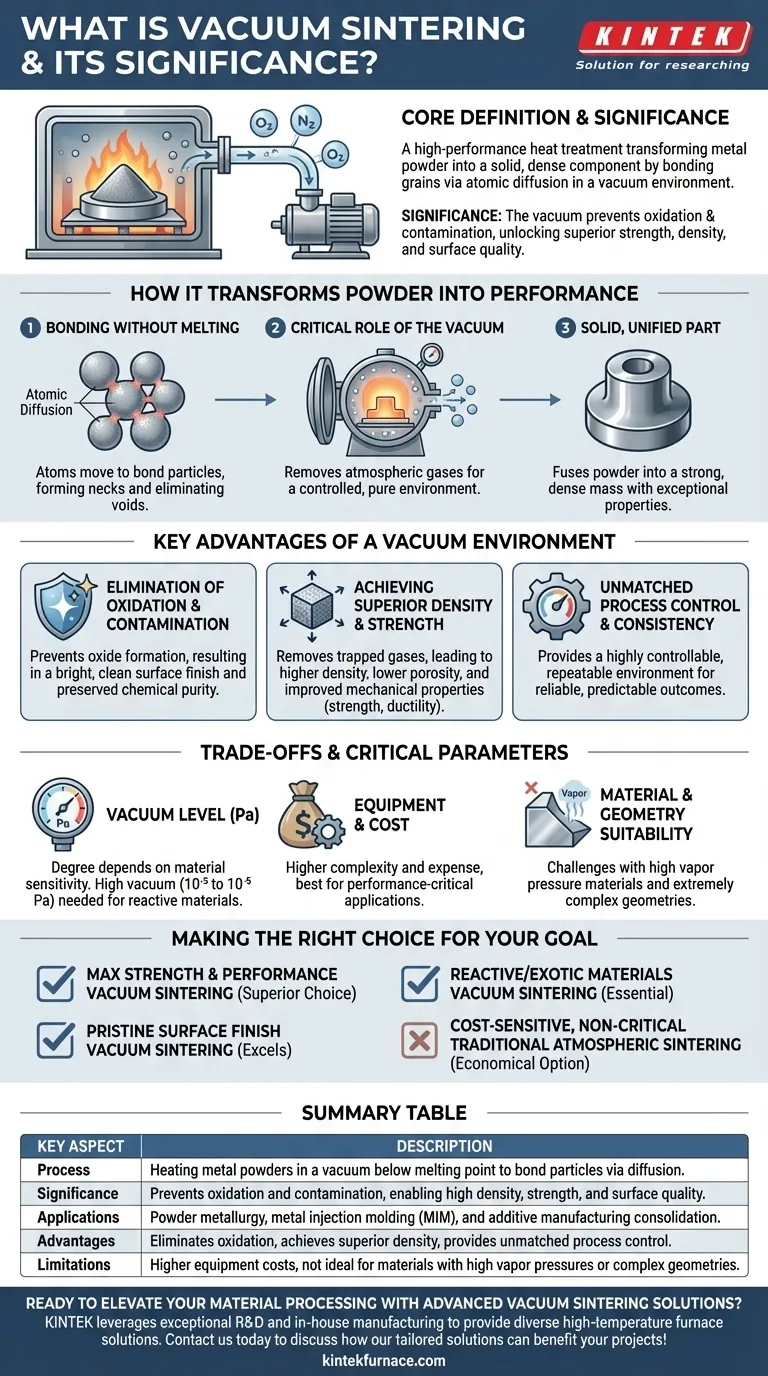

At its core, vacuum sintering is a high-performance heat treatment process used to transform metal powders into a solid, dense component. It works by heating the material in a vacuum chamber to a temperature below its melting point, causing the individual powder grains to bond together through diffusion, creating a strong, unified part with exceptional properties.

The true significance of this process lies not just in the heat, but in the vacuum. By removing atmospheric gases like oxygen, the vacuum environment prevents oxidation and contamination, which is the key to unlocking superior strength, density, and surface quality in the final product.

How Vacuum Sintering Transforms Powder into Performance

Vacuum sintering is a foundational process in powder metallurgy, metal injection molding (MIM), and for consolidating parts made via additive manufacturing. Its effectiveness comes from carefully controlling the environment in which the material is densified.

The Basic Principle: Bonding Without Melting

Sintering works by promoting atomic diffusion. At elevated temperatures, atoms on the surface of the powder particles become more mobile. They move across the contact points between particles, forming "necks" that grow over time, eventually eliminating the voids between them and fusing the powder into a solid mass.

The Critical Role of the Vacuum

The vacuum atmosphere is the defining factor that sets this process apart. Removing air and other gases from the furnace chamber accomplishes several critical goals simultaneously. This controlled environment is what enables the production of high-performance components.

The Key Advantages of a Vacuum Environment

Using a vacuum is a deliberate engineering choice designed to overcome the limitations of sintering in a standard atmosphere. The benefits directly impact the final part's mechanical properties and quality.

Elimination of Oxidation and Contamination

By removing oxygen and other reactive gases, the vacuum prevents the formation of oxides on the metal's surface. This results in a bright, clean surface finish that often requires no secondary mechanical rework, saving time and cost. It also preserves the chemical purity of the material.

Achieving Superior Density and Strength

Atmospheric gases can become trapped within the part during sintering, creating internal voids or porosity. A vacuum helps pull these trapped gases out, allowing the part to consolidate more effectively. This leads to higher density, lower porosity, and significantly improved mechanical properties like strength and ductility.

Unmatched Process Control and Consistency

A vacuum provides a pure and highly controllable environment. This ensures that the process is repeatable and consistent from one batch to the next. It eliminates variables introduced by atmospheric fluctuations, leading to more reliable and predictable outcomes, which is crucial for high-specification applications.

Understanding the Trade-offs and Critical Parameters

While powerful, vacuum sintering is not a universal solution. Understanding its operational parameters and limitations is key to using it effectively.

The Importance of Vacuum Level

Not all vacuums are equal. The required vacuum degree (measured in Pascals, Pa) depends on the material's sensitivity to oxidation. While a low vacuum (e.g., 10⁻¹ Pa) may be sufficient for some metals, highly reactive materials may require a high vacuum (10⁻³ to 10⁻⁵ Pa) for optimal protection.

Equipment and Cost Considerations

Vacuum furnaces are inherently more complex and expensive than their atmospheric counterparts. The initial capital investment and ongoing maintenance costs are higher. This makes the process best suited for applications where the performance and quality benefits justify the added expense.

Material and Geometry Suitability

The process is ideal for a wide range of metals but may not be suitable for materials with high vapor pressures, which can outgas and contaminate the vacuum system. Extremely complex part geometries can also pose a challenge for ensuring uniform heat distribution and complete gas removal.

Making the Right Choice for Your Goal

Selecting the right manufacturing process requires aligning the technique's capabilities with your project's non-negotiable requirements.

- If your primary focus is maximum strength and performance: Vacuum sintering is the superior choice for creating dense, pure parts with optimized mechanical properties for critical applications.

- If your primary focus is pristine surface finish: The process excels at producing bright, clean components that require minimal to no post-processing, reducing downstream costs.

- If your primary focus is on reactive or exotic materials: The protective nature of the vacuum is essential for processing metals that would be damaged by exposure to air at high temperatures.

- If your primary focus is cost-sensitive, non-critical components: Traditional atmospheric sintering may be a more economical choice if the risks of oxidation and slightly lower density are acceptable for the application.

By understanding that the vacuum is an active tool for material purification and densification, you can leverage this process to achieve a level of quality unattainable through conventional methods.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Heating metal powders in a vacuum below melting point to bond particles via diffusion. |

| Significance | Prevents oxidation and contamination, enabling high density, strength, and surface quality. |

| Applications | Powder metallurgy, metal injection molding (MIM), and additive manufacturing consolidation. |

| Advantages | Eliminates oxidation, achieves superior density, provides unmatched process control. |

| Limitations | Higher equipment costs, not ideal for materials with high vapor pressures or complex geometries. |

Ready to elevate your material processing with advanced vacuum sintering solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you achieve superior strength, density, and surface quality for critical applications. Contact us today to discuss how our tailored solutions can benefit your projects!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement