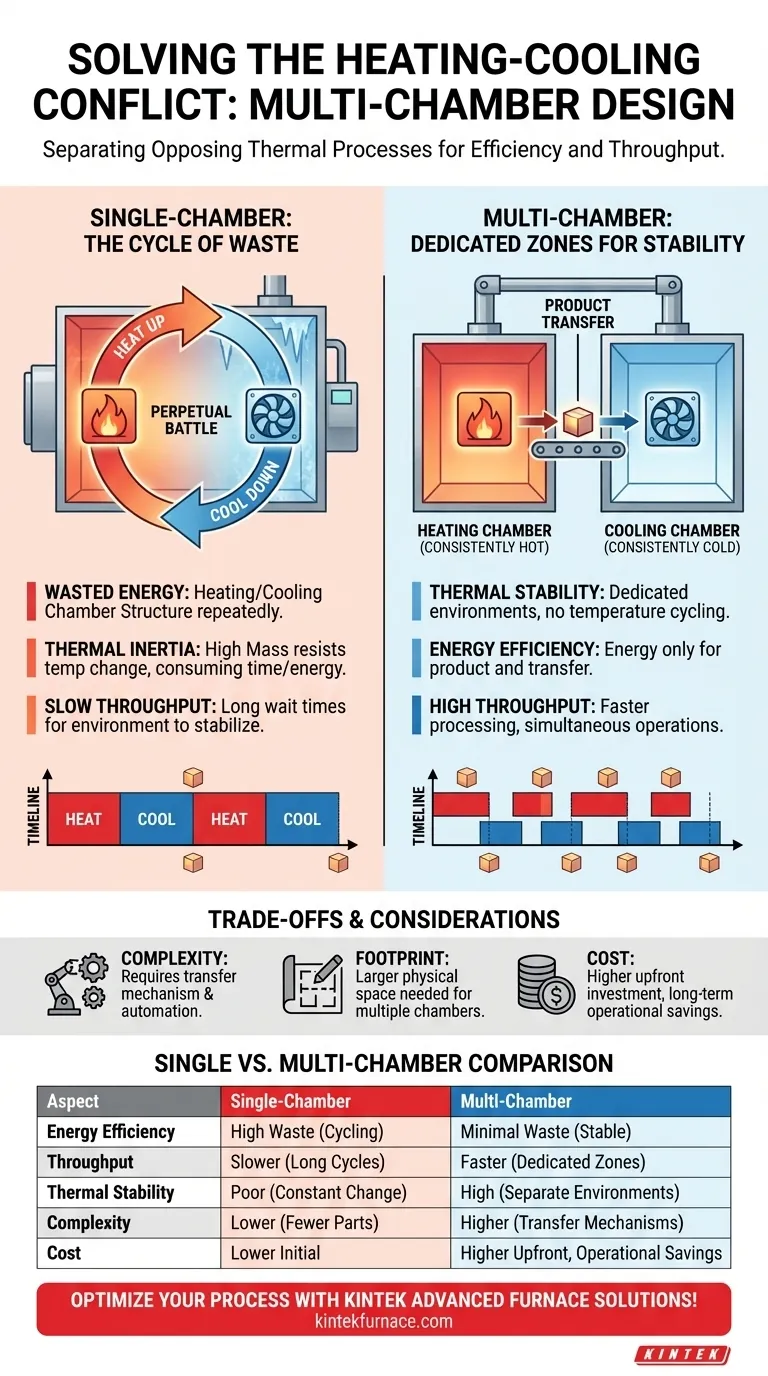

At its core, the multi-chamber design resolves the heating-cooling conflict by physically separating these opposing thermal processes into dedicated zones. This allows the heating chamber to remain consistently hot and the cooling chamber to remain consistently cold, eliminating the massive energy and time waste inherent in cycling a single space between temperature extremes.

The fundamental advantage of a multi-chamber system is that it stops fighting against thermal inertia. Instead of repeatedly forcing one chamber's mass up and down the temperature scale, it maintains thermal stability in separate zones, directing energy only where it's needed: into the product itself.

The Inefficiency of Single-Chamber Designs

To understand the solution, we must first appreciate the problem. Single-chamber systems, where an object is heated and then cooled in the same enclosure, are fundamentally inefficient for processes requiring rapid cycling.

The Cycle of Wasted Energy

In a single chamber, the process requires heating the chamber and the product. Then, to cool the product, you must also expend energy to cool the very chamber you just spent energy heating. This creates a perpetual, energy-intensive battle.

Thermal Inertia as an Obstacle

Every material has thermal inertia, a resistance to changes in temperature. The walls, racks, and atmosphere of a large chamber possess significant thermal mass. Overcoming this inertia during every heating and cooling phase consumes the majority of the energy and time.

Impact on Throughput

This constant battle against the chamber's own thermal mass leads directly to longer cycle times. The system must wait for the entire environment to heat up and then wait again for it to cool down, severely limiting process throughput.

How Multi-Chamber Architecture Solves the Conflict

A multi-chamber design circumvents these issues by assigning a dedicated, stable environment for each thermal state.

Dedicated Chambers for Thermal Stability

The heating chamber is designed and insulated to stay hot. The cooling chamber is engineered to stay cold. The object being processed is simply moved from one stable environment to the other.

Think of it like a professional kitchen. You don't use a single oven to bake a pizza, then flash-freeze ice cream, then bake another pizza. You have a hot oven and a cold freezer, and you move items between them.

Eliminating Redundant Energy Input

Because the heating chamber remains at its target temperature, energy is only required to heat the next product, not the entire chamber from a cooled state. The energy "invested" in heating the chamber's structure is retained, not discarded every cycle.

Shifting Focus from Environment to Product

This design shifts the operational focus from temperature-cycling a massive chamber to simply transferring the product. The energy and time are spent on the value-added process itself, not on fighting the physics of the surrounding equipment.

Understanding the Trade-offs

While thermally efficient, the multi-chamber approach is not a universal solution. It introduces its own set of engineering considerations that must be weighed.

Increased Mechanical Complexity

Moving a product between sealed, thermally-isolated chambers requires a reliable transfer mechanism. This adds moving parts, seals, and automation logic, which can increase maintenance requirements compared to a static single chamber.

Larger Physical Footprint

Two or more chambers will inherently occupy more floor space than one. In facilities where space is at a premium, this can be a significant limiting factor.

Higher Initial Capital Cost

The added complexity and materials associated with a multi-chamber system typically result in a higher upfront investment. The justification for this cost lies in the long-term operational savings from increased throughput and energy efficiency.

Making the Right Choice for Your Process

The decision between a single-chamber and a multi-chamber system depends entirely on your operational priorities.

- If your primary focus is high throughput and energy efficiency: The operational savings and speed of a multi-chamber design will almost certainly provide the best return on investment.

- If your primary focus is minimizing initial cost or facility footprint: A single-chamber system is superior for low-volume production, prototyping, or space-constrained applications.

- If your primary focus is process consistency at scale: The thermal stability of dedicated chambers in a multi-chamber system offers unparalleled repeatability for demanding industrial processes.

Ultimately, choosing the right thermal architecture is about matching the tool to the specific demands of the task.

Summary Table:

| Aspect | Single-Chamber Design | Multi-Chamber Design |

|---|---|---|

| Energy Efficiency | High waste from cycling temperatures | Minimal waste with stable zones |

| Throughput | Slower due to long cycle times | Faster with dedicated heating/cooling |

| Thermal Stability | Poor, constant temperature changes | High, maintains separate stable environments |

| Complexity | Lower, fewer moving parts | Higher, requires transfer mechanisms |

| Cost | Lower initial investment | Higher upfront, but operational savings |

Optimize your thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our multi-chamber designs can enhance your efficiency and throughput!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control