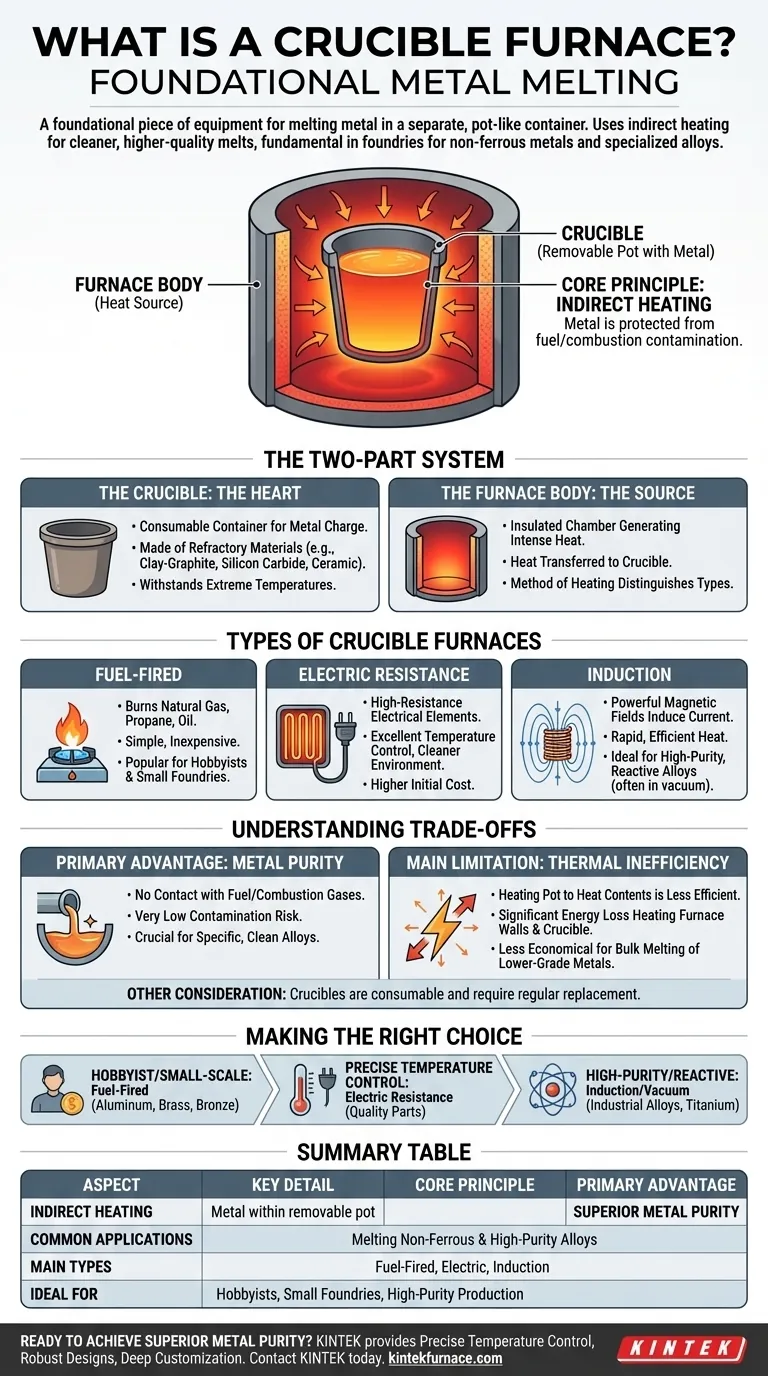

In essence, a crucible furnace is a foundational piece of equipment used for melting metal inside a separate, pot-like container. It is a type of foundry furnace where metal is placed within a high-temperature pot, known as a 'crucible,' which is then heated from the outside. These furnaces are fundamental in workshops and industrial foundries for melting non-ferrous metals like aluminum, brass, and bronze, as well as for specialized applications involving steel and other high-temperature alloys.

The core principle of a crucible furnace is indirect heating. By heating a separate, removable container (the crucible) rather than the metal directly, the molten metal is protected from contamination by fuel or combustion byproducts, ensuring a cleaner, higher-quality melt.

The Core Principle: How It Works

A crucible furnace operates on a simple but effective two-part system: the furnace body provides the heat, and the crucible contains the metal. This separation is its defining characteristic.

The Crucible: The Heart of the Furnace

The crucible is the removable container that holds the metal charge. Think of it as a heavy-duty cooking pot designed to withstand extreme temperatures.

It is made from refractory materials—materials engineered to resist heat and chemical reactions. Common crucible materials include clay-graphite, silicon carbide, and pure ceramic. The choice of material depends on the metal being melted and the furnace's heat source.

The Furnace Body: The Heat Source

The furnace itself is an insulated chamber designed to generate and contain intense heat, which is then transferred to the crucible. The method of heating is what primarily distinguishes different types of crucible furnaces.

This design ensures that the flame or heating elements never touch the metal, which is critical for maintaining the purity of the alloy.

Types of Crucible Furnaces

While the principle is the same, the method of generating heat varies significantly, impacting performance, cost, and application.

Fuel-Fired Furnaces

These are the most traditional and common types, especially in smaller shops. They burn fuel like natural gas, propane, or oil to heat the chamber.

They are relatively simple and inexpensive to build and operate, making them a popular choice for hobbyists and small-scale brass and aluminum foundries.

Electric Resistance Furnaces

These furnaces use high-resistance electrical elements, similar to those in a kiln or electric oven, to generate heat. The elements surround the crucible and radiate heat inward.

This method offers excellent temperature control and a cleaner operating environment compared to fuel-fired furnaces, but at a higher initial equipment cost.

Induction Furnaces

This is the most modern and advanced method. An induction furnace uses powerful magnetic fields to induce an electric current directly within the crucible (if conductive) or a secondary conductive sleeve. This current generates intense, rapid, and highly efficient heat.

Often performed in a vacuum, this is the preferred method for melting high-purity steel, titanium, and other reactive alloys that must be protected from atmospheric gases.

Understanding the Trade-offs

No single tool is perfect for every job. The crucible furnace has distinct advantages and clear limitations.

The Primary Advantage: Metal Purity

Because the metal never comes into contact with the fuel or combustion gases, there is a very low risk of contamination. This is crucial for creating specific alloys where even trace amounts of impurities like hydrogen or sulfur can ruin the final casting.

The Main Limitation: Thermal Inefficiency

Heating a pot in order to heat its contents is inherently less efficient than heating the contents directly. A significant amount of energy is lost in heating the furnace walls and the crucible itself.

For bulk melting of lower-grade metals like scrap iron, other furnace types (like a cupola or electric arc furnace) are far more energy-efficient and economical.

Other Considerations: Cost and Lifespan

Crucibles are consumable items. They degrade over time from thermal shock and chemical attack by molten metal. Their replacement represents a recurring operational cost that must be factored into any foundry's budget.

Making the Right Choice for Your Goal

Selecting a crucible furnace depends entirely on the material you are working with and the quality you need to achieve.

- If your primary focus is hobbyist metal casting or small-scale production: A simple fuel-fired crucible furnace offers the lowest barrier to entry for working with aluminum, brass, and bronze.

- If your primary focus is precise temperature control for quality parts: An electric resistance furnace provides superior consistency and a cleaner melt, ideal for small commercial foundries.

- If your primary focus is producing high-purity industrial alloys or reactive metals: A vacuum induction crucible furnace is the industry standard for preventing contamination and ensuring absolute metallurgical integrity.

Understanding the simple, effective role of the crucible is the key to mastering this fundamental metal-melting technology.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Core Principle | Indirect heating of metal within a removable, high-temperature pot (crucible). |

| Primary Advantage | Superior metal purity by protecting the melt from fuel and combustion contaminants. |

| Common Applications | Melting non-ferrous metals (aluminum, brass, bronze) and high-purity alloys (steel, titanium). |

| Main Types | Fuel-Fired (propane, gas), Electric Resistance, Induction (including vacuum). |

| Ideal For | Hobbyists, small-scale foundries, and high-purity industrial alloy production. |

Ready to Achieve Superior Metal Purity in Your Lab or Foundry?

Whether you are a hobbyist caster or an industrial producer of high-purity alloys, the right furnace is critical to your success. KINTEK's advanced high-temperature furnace solutions, including crucible and vacuum atmosphere furnaces, are engineered for exceptional performance and reliability.

We provide:

- Precise Temperature Control for consistent, high-quality melts.

- Robust Designs that ensure clean operation and protect your metal from contamination.

- Strong Deep Customization Capability to tailor a furnace solution that meets your unique experimental or production requirements.

Leverage our exceptional R&D and in-house manufacturing expertise to find the perfect melting solution for your needs.

Contact KINTEL today to discuss your project and discover how our furnaces can enhance your work!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety