At its core, a high-temperature vacuum furnace enhances heat treatment and sintering by creating an ultra-pure, controlled environment. For heat treating metals, this prevents undesirable reactions like oxidation and decarburization, leading to superior mechanical properties. For sintering, the vacuum removes trapped gases and impurities, resulting in purer, denser final products.

The primary benefit of a vacuum furnace is not merely the absence of air, but the absolute control it provides over the material's environment. This control unlocks a level of material purity, structural integrity, and process consistency that is unattainable in conventional atmospheric furnaces.

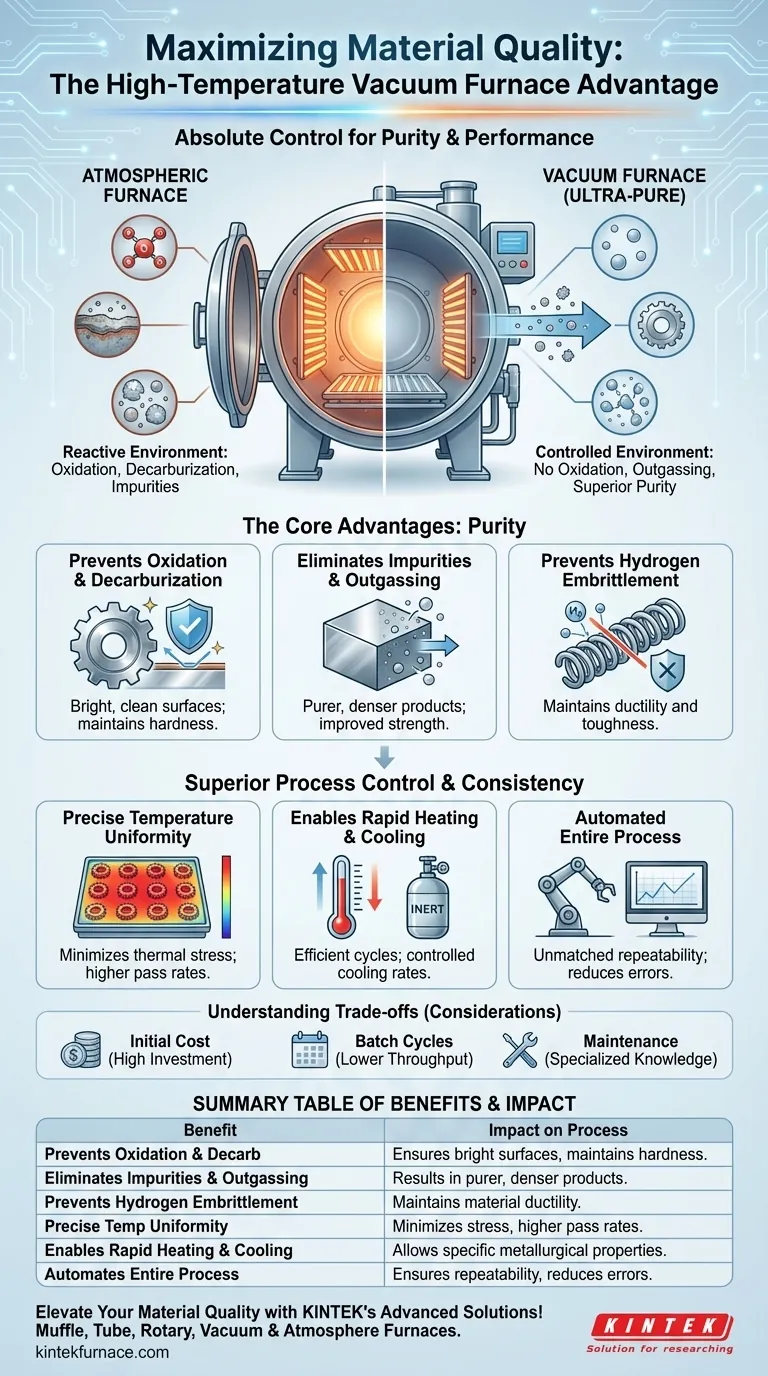

The Fundamental Advantage: Environmental Purity

The defining feature of a vacuum furnace is its ability to remove the atmosphere—and all its reactive elements—from the heating chamber. This has profound implications for the material being processed.

Preventing Oxidation and Decarburization

When heating metals in the presence of oxygen, a layer of oxide scale forms on the surface. A vacuum environment eliminates this, ensuring parts emerge with a bright, clean surface finish that requires no subsequent cleaning or machining.

For steels, the vacuum also prevents decarburization, the loss of carbon from the surface, which is critical for maintaining the material's designed hardness and wear resistance.

Eliminating Impurities and Outgassing

During sintering of powdered metals, ceramics, or carbides, trapped gases can create voids, reducing the final density and strength of the part. The vacuum actively pulls these impurity gases and moisture out of the material before and during heating.

This outgassing and degassing function results in a purer, more compact final product with significantly improved physical properties.

Preventing Hydrogen Embrittlement

Certain materials are susceptible to hydrogen embrittlement, where absorbed hydrogen atoms make the metal brittle and prone to fracture. A vacuum furnace effectively removes hydrogen from the environment, mitigating this risk and ensuring the material's intended ductility and toughness.

Superior Process Control and Consistency

Beyond purity, a vacuum furnace offers an unparalleled level of control over the entire thermal cycle, leading to highly repeatable and reliable outcomes.

Achieving Precise Temperature Uniformity

Modern vacuum furnaces are engineered for exceptional temperature uniformity throughout the chamber. This ensures that every part, regardless of its position, experiences the exact same thermal profile.

This uniform heating minimizes thermal stress and distortion, which is critical for complex or thin-walled components, leading to a much higher pass rate for finished parts.

Enabling Rapid Heating and Cooling

With no air to transfer heat via convection, heating is primarily done through radiation, which can be very fast and efficient at high temperatures.

Furthermore, many vacuum furnaces incorporate systems for rapid cooling or quenching. This is often achieved by backfilling the sealed chamber with a high-purity inert gas like argon or nitrogen, allowing for controlled cooling rates that are essential for achieving specific metallurgical properties.

Automating the Entire Process

Vacuum furnace operations are typically managed by sophisticated computer control systems. The entire cycle—from pump-down and heating to soaking, quenching, and cooling—can be programmed and executed automatically.

This "all-in-one" capability ensures that every batch is processed with unmatched repeatability, eliminating the process variables and operator-induced errors common in older technologies.

Understanding the Trade-offs

While the benefits are significant, a vacuum furnace is not a universal solution. It is essential to understand its limitations to make an informed decision.

Initial Equipment Cost

The primary barrier to adoption is cost. A high-temperature vacuum furnace represents a significant capital investment compared to a conventional atmospheric furnace due to the complexity of the vacuum pumps, chamber construction, and control systems.

Batch Processing Cycles

Most vacuum furnaces operate in batches, meaning a single load is processed from start to finish before the next can begin. This can limit throughput compared to some continuous-belt atmospheric furnaces used in high-volume production.

Maintenance Complexity

The vacuum system, including pumps, seals, and instrumentation, requires specialized knowledge for maintenance and repair. Maintaining a high-quality vacuum is critical for performance and demands a rigorous preventative maintenance schedule.

Making the Right Choice for Your Process

Choosing a vacuum furnace depends on prioritizing specific outcomes for your product and operation.

- If your primary focus is material purity and performance: The vacuum furnace is the definitive choice for eliminating unwanted surface reactions and internal impurities.

- If your primary focus is process repeatability and automation: The precise, computer-controlled environment of a vacuum furnace delivers unmatched consistency from batch to batch.

- If your primary focus is reducing post-processing steps: The clean, scale-free finish from a vacuum furnace can eliminate costly and time-consuming secondary operations like cleaning or grinding.

Ultimately, investing in a vacuum furnace is a strategic move to elevate material quality by gaining complete command over the thermal processing environment.

Summary Table:

| Benefit | Impact on Process |

|---|---|

| Prevents Oxidation & Decarburization | Ensures bright, clean surfaces and maintains material hardness |

| Eliminates Impurities & Outgassing | Results in purer, denser products with improved strength |

| Prevents Hydrogen Embrittlement | Maintains material ductility and toughness |

| Achieves Precise Temperature Uniformity | Minimizes thermal stress and distortion for higher pass rates |

| Enables Rapid Heating & Cooling | Allows controlled cooling for specific metallurgical properties |

| Automates Entire Process | Ensures unmatched repeatability and reduces operator errors |

Elevate your material quality with KINTEK's advanced high-temperature furnace solutions! We specialize in Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization to meet your unique experimental needs. Contact us today to discuss how our expertise in R&D and in-house manufacturing can optimize your heat treatment and sintering processes for superior results.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing