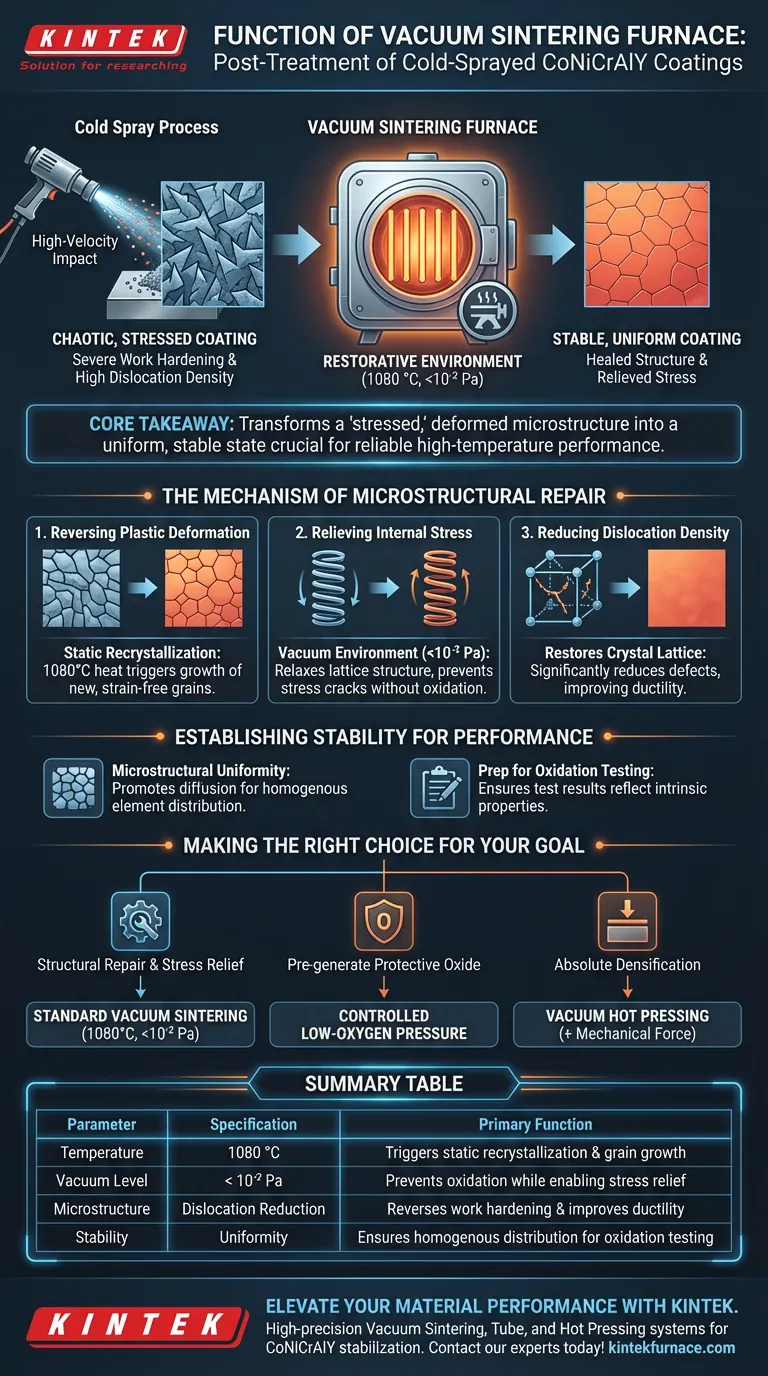

The primary function of a vacuum sintering furnace in this context is to act as a restorative environment that heals the structural damage caused by the cold spray process. By maintaining a specific temperature of 1080 °C and a vacuum pressure lower than 10⁻² Pa, the furnace induces static recrystallization to repair zones of intense plastic deformation and relieve internal stresses within the CoNiCrAlY coating.

Core Takeaway: Cold spraying relies on high-velocity impact, which inherently creates a "stressed" coating characterized by severe work hardening and high dislocation density. The vacuum sintering furnace reverses these effects, transforming a deformed microstructure into a uniform, stable state required for reliable high-temperature performance.

The Mechanism of Microstructural Repair

Reversing Plastic Deformation

The cold spray process builds coatings through kinetic energy, resulting in particles that are heavily deformed upon impact. The vacuum sintering furnace addresses this by exposing the coating to high heat (1080 °C).

This thermal energy triggers static recrystallization. The deformed grains nucleate and grow into new, strain-free grains, effectively repairing the plastic deformation zones.

Relieving Internal Stress

High-velocity impact creates significant residual stress within the material. If left untreated, this stress can lead to premature coating failure or delamination.

The vacuum environment (<10⁻² Pa) allows the material to undergo stress relief without the interference of atmospheric gases. This relaxes the lattice structure and prevents the formation of stress-induced cracks.

Reducing Dislocation Density

The mechanical impact of spraying causes work hardening, which results in a high density of dislocations (defects) in the crystal structure.

Post-treatment in the furnace significantly reduces this dislocation density. This restoration of the crystal lattice improves the ductility and overall mechanical integrity of the coating.

Establishing Stability for Performance

Achieving Microstructural Uniformity

A raw cold-sprayed coating often exhibits a chaotic, heterogeneous structure. The sintering process promotes diffusion, leading to a more homogenous distribution of elements.

This improved microstructural uniformity ensures that the coating responds predictably to thermal and mechanical loads during service.

Preparing for Oxidation Testing

The ultimate goal of this post-treatment is to establish a stable organizational foundation.

By stabilizing the microstructure and removing defects, the furnace prepares the CoNiCrAlY coating for high-temperature oxidation testing. This ensures that test results reflect the material's intrinsic properties rather than artifacts of the spraying process.

Operational Criticalities and Trade-offs

The Necessity of High Vacuum

Maintaining a vacuum pressure lower than 10⁻² Pa is critical. If the pressure rises or oxygen is introduced unintentionally, the coating may undergo uncontrolled oxidation rather than repair.

Thermal Precision

The temperature of 1080 °C is specifically tuned for CoNiCrAlY recrystallization.

Operating below this threshold may fail to induce necessary grain growth. Operating significantly above it risks altering the phase composition or damaging the substrate interface.

Sintering vs. Hot Pressing

It is important to distinguish standard vacuum sintering from vacuum hot pressing.

While standard sintering relies on heat and time, hot pressing adds axial pressure to mechanically force densification. Standard sintering is generally sufficient for stress relief, but hot pressing may be required if the primary goal is maximizing density and eliminating porosity.

Making the Right Choice for Your Goal

To select the correct post-treatment protocol, you must identify your specific coating requirements:

- If your primary focus is structural repair and stress relief: Adhere strictly to the primary reference standards of 1080 °C and <10⁻² Pa to drive static recrystallization and reduce work hardening.

- If your primary focus is pre-generating a protective oxide layer: You may need to deviate from high vacuum to a controlled low-oxygen partial pressure environment to induce selective aluminum oxidation (α-Al2O3).

- If your primary focus is absolute densification: Consider using a vacuum hot pressing furnace, which utilizes the synergistic effect of heat and mechanical force to eliminate pores.

By precisely controlling the thermal and vacuum environment, you transform a kinetically deposited layer into a metallurgically stable component ready for service.

Summary Table:

| Process Parameter | Required Specification | Primary Function |

|---|---|---|

| Temperature | 1080 °C | Triggers static recrystallization and grain growth |

| Vacuum Level | < 10⁻² Pa | Prevents oxidation while enabling stress relief |

| Microstructure | Dislocation Reduction | Reverses work hardening and improves ductility |

| Stability | Uniformity | Ensures homogenous distribution for oxidation testing |

Elevate Your Material Performance with KINTEK

Don't let residual stress and work hardening compromise your cold-sprayed coatings. Backed by expert R&D and world-class manufacturing, KINTEK provides high-precision Vacuum Sintering, Tube, and Vacuum Hot Pressing systems specifically designed to stabilize CoNiCrAlY and other high-temp alloys.

Whether you require standard thermal repair or advanced densification, our customizable lab furnaces offer the thermal precision and vacuum integrity your research demands.

Ready to optimize your post-treatment process? Contact our technical experts today to find the perfect furnace solution for your unique coating needs!

Visual Guide

References

- Xudong Sun, Zhigang Zheng. Microstructure and High-Temperature Oxidation Behavior of Cold-Sprayed CoNiCrAlY Coatings Deposited by Different Propellent Gases. DOI: 10.3390/coatings15020123

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum sublimation furnace with rheological movement benefit high-moisture coal? Optimize Production Speed

- What types of heat treatment processes are performed in vacuum furnaces? Achieve Superior Metallurgical Control and Quality

- What is vacuum brazing and what materials does it primarily join? Discover High-Purity Joining for Superior Bonds

- What are the key uses of vacuum annealing furnaces? Achieve Superior Material Integrity and Purity

- What is the temperature range of laboratory vacuum furnaces and what factors influence it? Find the Perfect Fit for Your Lab

- How does a vacuum impregnation device facilitate PCMs into biomimetic composites? Boost Filling Rates to 96%

- What is the specific function of the high vacuum in SiC/Cu-Al2O3 sintering? Achieve 1.5x10^-2 Pa for Peak Density

- Why use vacuum and argon in pulse solidification? Protect your Aluminum-Silicon alloys from oxidation and contamination