A vacuum sublimation furnace equipped with rheological movement capabilities transforms the processing of coal adsorbents by enabling the direct treatment of materials with moisture contents as high as 20%. By utilizing inclined surface columns and vibration feeding, this design forces bulk materials to move through the high-temperature zone in a fluid-like state under gravity, completely eliminating the need for a separate, time-consuming pre-drying stage.

The integration of gravity-induced rheological flow increases the specific surface area of the material exposed to heat, allowing for the efficient, direct processing of high-moisture adsorbents and significantly streamlining production lines.

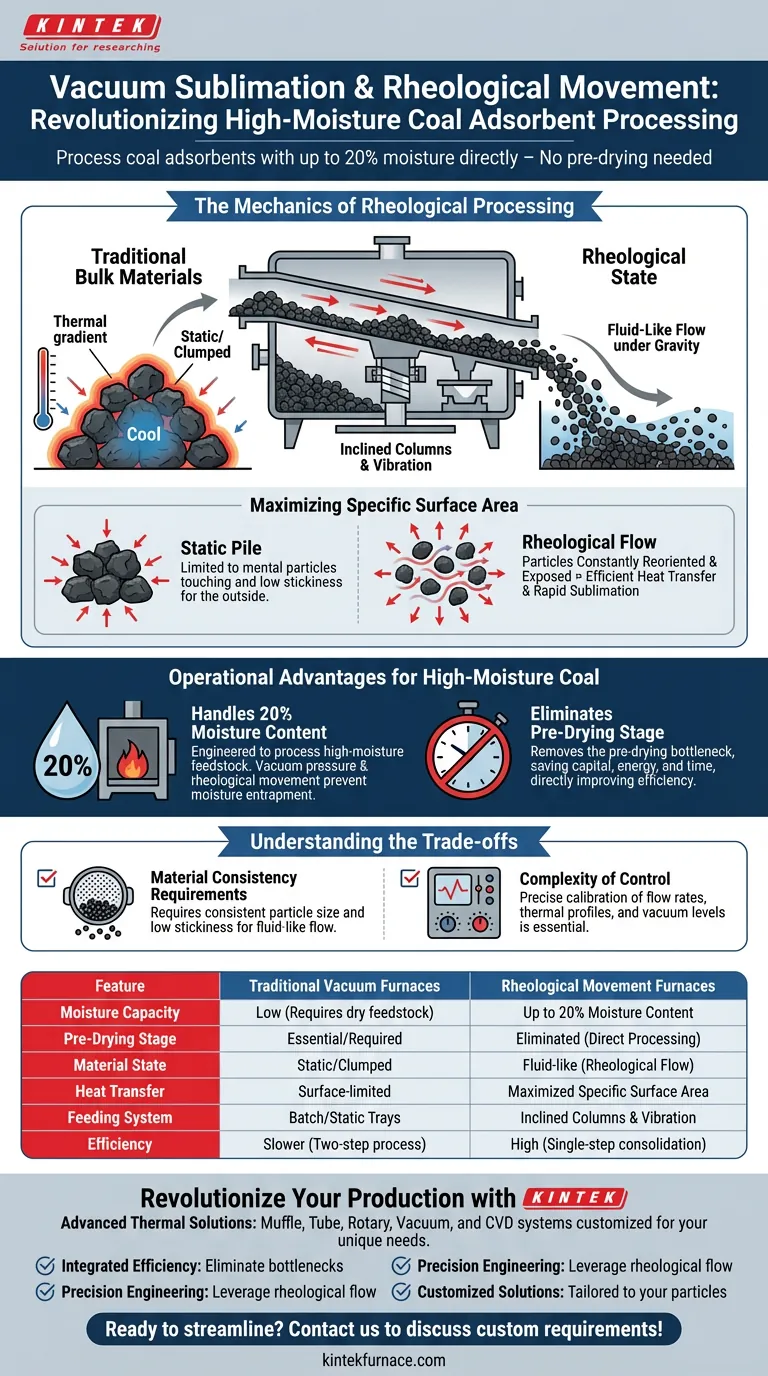

The Mechanics of Rheological Processing

To understand why this furnace design is superior for high-moisture applications, one must look at how it manipulates the physical state of the material.

Inducing a Fluid-Like State

Standard bulk materials often clump or stack, creating thermal gradients where the outside is hot and the inside remains cool.

This furnace uses inclined surface columns combined with vibration feeding systems.

This combination allows solid bulk materials to move through the furnace in a rheological state. Essentially, the solid particles flow like a fluid under the influence of gravity.

Maximizing Specific Surface Area

The primary technical advantage of this flow state is the maximization of surface area.

As the material flows rheologically, particles are constantly reoriented and exposed.

This increases the specific surface area available for heat transfer and sublimation, ensuring that moisture is released rapidly and evenly, rather than being trapped inside a static pile.

Operational Advantages for High-Moisture Coal

The defining feature of this technology is its ability to handle wet feedstock that would stall traditional systems.

Handling 20% Moisture Content

Standard vacuum furnaces often require materials to be relatively dry to maintain vacuum integrity and process speed.

This specific design is engineered to process coal adsorbents with moisture levels up to 20%.

The combination of vacuum pressure (which lowers the boiling point of water) and the rheological movement (which prevents moisture entrapment) allows the furnace to handle this significant water load effectively.

Eliminating the Pre-Drying Stage

In conventional workflows, high-moisture coal requires a dedicated pre-drying phase before it enters the sublimation furnace.

This adds capital expense, energy costs, and time to the manufacturing cycle.

By handling the moisture directly within the sublimation zone, this furnace removes the pre-drying bottleneck, directly improving overall production efficiency.

Understanding the Trade-offs

While this technology offers significant efficiency gains, it is essential to consider the operational constraints inherent in rheological processing.

Material Consistency Requirements

Rheological flow relies heavily on the physical characteristics of the feedstock.

If the coal adsorbent is inconsistent in particle size or excessively sticky, it may resist the fluid-like flow despite the vibration.

Operators must ensure the feedstock falls within a specific physical range to maintain the benefits of the inclined gravity feed.

Complexity of Control

Introducing vibration and flow mechanics adds variables to the process control equation.

Unlike a static batch furnace, you must manage flow rates in tandem with thermal profiles and vacuum levels.

Precise calibration is required to ensure the material spends the exact amount of time in the hot zone to achieve sublimation without under-processing.

Making the Right Choice for Your Goal

When evaluating this furnace technology for your production line, consider your specific processing bottlenecks.

- If your primary focus is Production Speed: This system is ideal because it consolidates drying and sublimation into a single step, removing the pre-drying stage entirely.

- If your primary focus is Feedstock Versatility: Ensure your material characteristics (particle size and stickiness) are compatible with gravity-fed vibration systems to guarantee consistent rheological flow.

By leveraging rheological movement, you turn the physical challenge of high-moisture content into a manageable variable, streamlining your path to a finished adsorbent product.

Summary Table:

| Feature | Traditional Vacuum Furnaces | Rheological Movement Furnaces |

|---|---|---|

| Moisture Capacity | Low (Requires dry feedstock) | Up to 20% Moisture Content |

| Pre-Drying Stage | Essential/Required | Eliminated (Direct Processing) |

| Material State | Static/Clumped | Fluid-like (Rheological Flow) |

| Heat Transfer | Surface-limited | Maximized Specific Surface Area |

| Feeding System | Batch/Static Trays | Inclined Columns & Vibration |

| Efficiency | Slower (Two-step process) | High (Single-step consolidation) |

Revolutionize Your Adsorbent Production with KINTEK

Is your production line stalled by time-consuming pre-drying stages? KINTEK specializes in advanced thermal solutions designed to handle your toughest material challenges. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to your unique processing needs.

By choosing KINTEK, you gain:

- Integrated Efficiency: Eliminate bottlenecks with furnaces capable of handling high-moisture feedstock directly.

- Precision Engineering: Leverage gravity-induced rheological flow for superior heat transfer and material consistency.

- Customized Solutions: Our high-temp systems are tailored to your specific particle size and sublimation requirements.

Ready to streamline your lab or industrial workflow? Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Bagdaulet Kenzhaliyev, Xeniya Linnik. Preliminary Removal of Mercury from Depleted Coal Sorbents by Thermal Vacuum Method with Associated Extraction of Precious Metal Composite. DOI: 10.3390/jcs8090367

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why must NaF and KF raw materials be processed in a vacuum oven for FUNaK synthesis? Ensure Purity and Safety

- What advantages does vacuum carburizing offer in terms of part quality and consistency? Achieve Superior Heat Treatment with Minimal Distortion

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- Why is a high-precision vacuum oven necessary for RGO/PI composite films? Ensure Defect-Free Graded Heat Treatment

- What are the safety precautions related to the temperature of a vacuum furnace? Ensure Operator and Equipment Protection

- How does a vertical vacuum furnace handle long or large loads? Optimize Stability and Uniformity for Heavy Components

- What are the primary process functions of a vacuum oven in Fe3O4/C@PM synthesis? Ensure Material Integrity.

- What conditions does a vacuum furnace provide for Nb3Sn repair? Precision Heat and High Vacuum for Superconductors