The fundamental safety precautions for a vacuum furnace's temperature involve never exceeding its maximum rated temperature, constantly monitoring its operation, and never opening the chamber door while the internal temperature is high (e.g., above 600°C). If any abnormalities are detected, the power must be disconnected immediately.

Managing a vacuum furnace is not just about following a checklist; it's about understanding the unique risks created by extreme heat in a controlled atmosphere. Your vigilance is the most critical safety component.

The Core Principles of Temperature Safety

Operating a vacuum furnace involves managing immense thermal energy. The safety protocols are designed to protect not only the operator but also the equipment and the material being processed.

Adhering to Maximum Temperature Limits

A vacuum furnace has a specified maximum operating temperature, which can be as high as 2600°C. Exceeding this limit, even for a short time, can cause permanent damage to the heating elements, insulation, and the structural integrity of the furnace chamber.

The Danger of Prolonged High-Heat Operation

Running the furnace at its maximum rated temperature for extended periods accelerates wear and tear on all components. This can lead to premature failure, costly repairs, and potential safety hazards.

The Critical Role of Active Monitoring

A vacuum furnace must never be left unattended during operation. An operator's constant presence is required to monitor temperature changes and other system parameters. Subtle fluctuations can be the first sign of a developing issue that requires immediate intervention.

Managing Thermal Hazards During Operation

The most dangerous phases of operation are often during the heat-up and cool-down cycles, where the potential for thermal shock and operator injury is highest.

Why the Furnace Door Stays Closed

You must not open the furnace door when the internal temperature is above 600°C. Opening the door introduces oxygen, which can cause immediate, and often destructive, oxidation of the hot material inside. It also creates a severe risk of thermal shock to the furnace components and a significant burn hazard for the operator.

The Importance of Natural Cooling

Allowing the furnace chamber to cool down naturally is a critical safety step. A controlled, gradual temperature decrease prevents thermal shock, which can crack or warp both the material inside and the furnace's internal components.

Responding to System Abnormalities

If you observe any abnormal behavior—such as unexpected temperature spikes, fluctuating vacuum levels, or strange noises—the immediate and correct response is to disconnect the power. This action stops the process and prevents a minor issue from escalating into a catastrophic failure. The unit must then be inspected by a professional.

Understanding the System and Its Limitations

Your safety depends on understanding how the furnace's systems work together and recognizing their inherent trade-offs.

The Link Between Control Systems and Safety

The temperature control system, whether it's a PID, touch screen, or PLC controller, is a primary safety feature. It relies on thermocouples for accurate temperature measurement. A malfunctioning thermocouple can provide false readings, leading the controller to overheat the furnace dangerously.

The Impact of Sensor Accuracy

Accurate temperature measurement is non-negotiable for safe operation. As seen in vertical furnace designs, proper thermocouple placement is key to getting a true reading of the workload. If you cannot trust your temperature data, you cannot safely or effectively run your process.

Material and Process Compatibility

Before starting any process, you must ensure the furnace's capabilities—its temperature range, vacuum level, and cooling system—are appropriate for the materials being treated. Heating incompatible materials can lead to outgassing or reactions that compromise the vacuum and create unforeseen hazards.

Making the Right Choice for Your Goal

Your operational focus will determine which safety protocols are most critical to emphasize in your procedures.

- If your primary focus is operator safety: Enforce the non-negotiable rules of never leaving the furnace unattended and never opening the door above the specified safe temperature.

- If your primary focus is equipment longevity: Stress the importance of operating below the absolute maximum temperature and avoiding unnecessarily prolonged cycles at peak heat.

- If your primary focus is process quality: Emphasize the need for precise temperature control and the discipline of allowing for a full, natural cooldown cycle to ensure material integrity.

Ultimately, a deep respect for the furnace's power and a commitment to vigilant operation are the cornerstones of a safe and successful outcome.

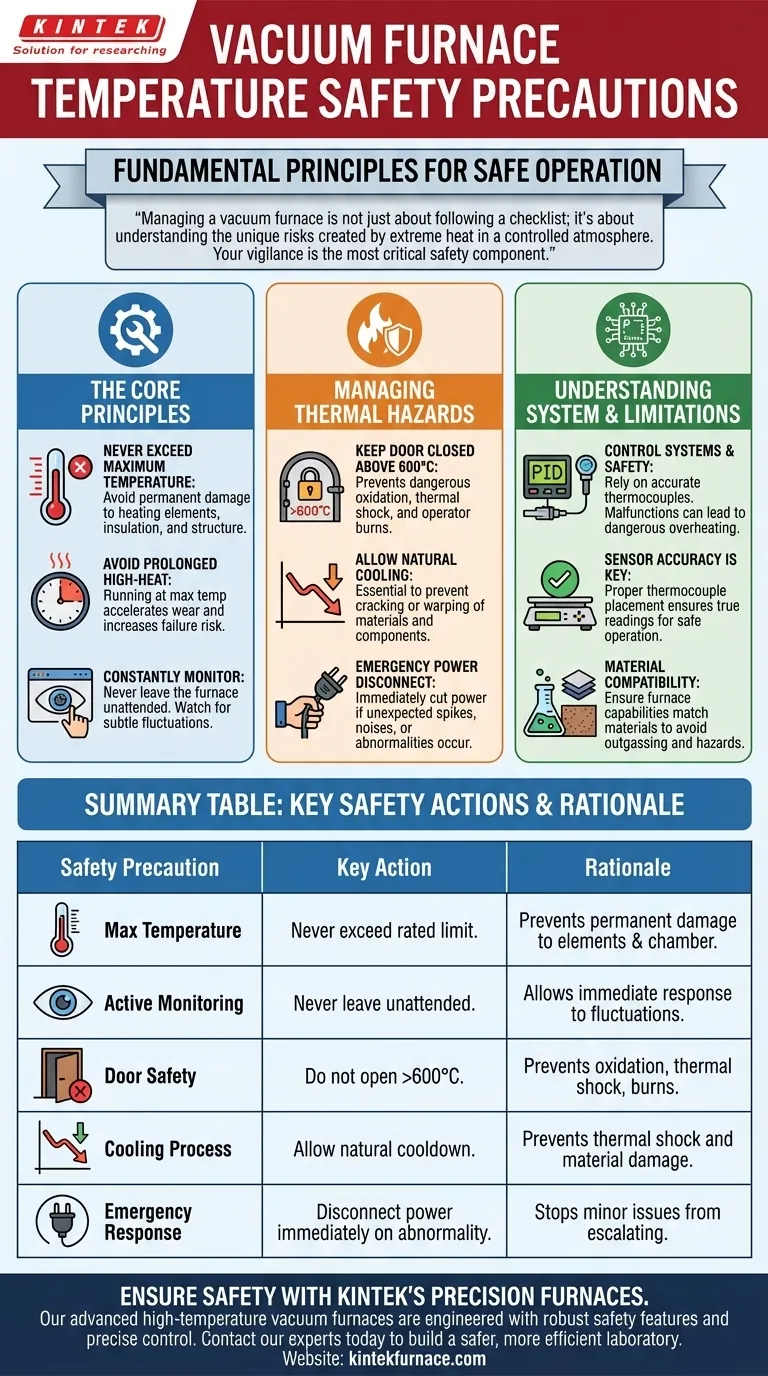

Summary Table:

| Safety Precaution | Key Action | Rationale |

|---|---|---|

| Max Temperature | Never exceed the furnace's rated limit. | Prevents permanent damage to heating elements and chamber structure. |

| Active Monitoring | Never leave the furnace unattended during operation. | Allows for immediate response to temperature fluctuations or abnormalities. |

| Door Safety | Do not open the door when temperature is >600°C. | Prevents oxidation, thermal shock, and severe operator burns. |

| Cooling Process | Allow for a full, natural cooldown cycle. | Prevents thermal shock that can crack or warp materials and components. |

| Emergency Response | Disconnect power immediately if abnormalities are detected. | Stops a minor issue from escalating into a catastrophic failure. |

Ensure your laboratory's safety and process integrity with a furnace built for precision and reliability.

At KINTEK, we understand that safety is paramount when working with extreme temperatures. Our advanced high-temperature vacuum furnaces are engineered with robust safety features and precise control systems to mitigate risks. Leveraging our exceptional in-house R&D and manufacturing capabilities, we provide solutions like our Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, complemented by deep customization to meet your unique experimental requirements.

Let us help you build a safer, more efficient laboratory. Contact our experts today to discuss your specific needs and how our reliable furnace solutions can protect your operators, your equipment, and your research outcomes.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity