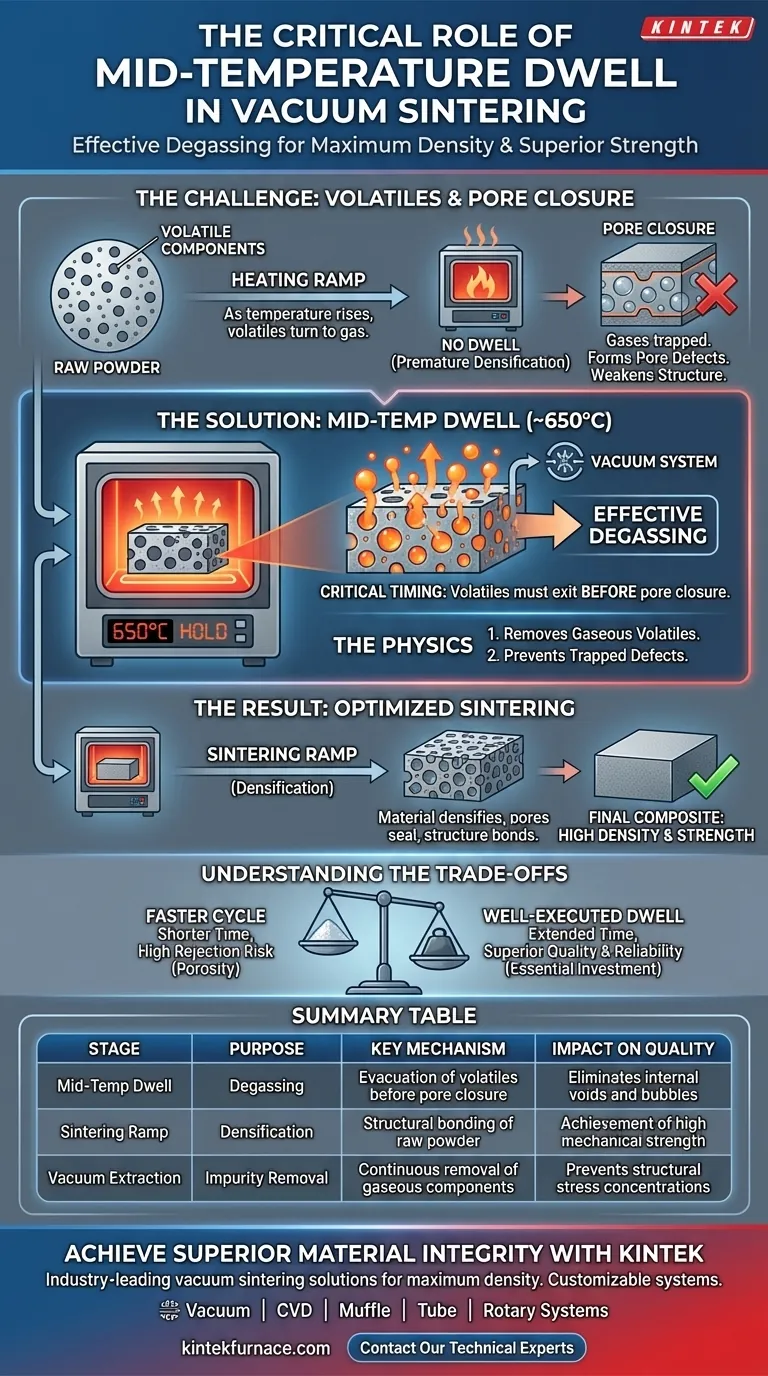

The primary purpose of a mid-temperature dwell stage is effective degassing. By holding the temperature steady—often around 650°C—you allow volatile components within the raw powder to escape before the material begins to densify. This prevents gases from becoming trapped inside the structure, which is essential for avoiding defects.

By pausing the heating process before pores close, you ensure that impurities are evacuated rather than sealed inside the material. This step is the defining factor in achieving maximum density and superior mechanical strength in the final composite.

The Physics of the Dwell Stage

Removing Volatile Components

Raw powder materials inevitably contain volatile components. As the furnace heats up, these components transition into a gaseous state.

The dwell stage provides a specific window of time for these gases to fully exit the material and be removed by the vacuum system.

Timing is Critical

This degassing process must occur before the material reaches the sintering temperature.

If the temperature continues to rise without pausing, the material will begin to densify. Once densification starts, the physical structure of the material begins to change, leading to pore closure.

Why "Pore Closure" Matters

The Trap of Premature Densification

If the material densifies while volatiles are still generating, the escape routes for the gas are cut off.

The outer surface of the material creates a seal, effectively trapping the gas inside the bulk of the material.

Formation of Pore Defects

Trapped gases result in pore defects—voids or bubbles within the final product.

These defects disrupt the internal structure of the material. They act as stress concentrators, significantly reducing the material's reliability.

Impact on Structural Integrity

The ultimate goal of vacuum sintering is to produce a composite with high density and mechanical strength.

Skipping or shortening the mid-temperature dwell compromises this goal. You cannot achieve maximum density if the internal volume is occupied by trapped gas pockets.

Understanding the Trade-offs

Cycle Time vs. Part Quality

Implementing a dwell stage inherently extends the total cycle time of the sintering process.

While this increases the time required per batch, it is a necessary investment. The alternative—a faster cycle with no dwell—risks a high rejection rate due to internal porosity and structural weakness.

Optimizing Your Sintering Profile

To ensure you are getting the most out of your vacuum sintering process, consider your specific performance requirements.

- If your primary focus is Defect Elimination: Ensure your dwell time is sufficiently long to evacuate all volatiles before the temperature ramp resumes.

- If your primary focus is Mechanical Strength: Verify that the dwell temperature is strictly set below the point of pore closure to prevent compromising the material's density.

A well-executed dwell stage is the difference between a porous, weak part and a fully dense, high-performance composite.

Summary Table:

| Stage | Purpose | Key Mechanism | Impact on Quality |

|---|---|---|---|

| Mid-Temp Dwell | Degassing | Evacuation of volatiles before pore closure | Eliminates internal voids and bubbles |

| Sintering Ramp | Densification | Structural bonding of raw powder | Achievement of high mechanical strength |

| Vacuum Extraction | Impurity Removal | Continuous removal of gaseous components | Prevents structural stress concentrations |

Achieve Superior Material Integrity with KINTEK

Don't let trapped gases compromise your production quality. KINTEK provides industry-leading vacuum sintering solutions designed to deliver maximum density and mechanical strength. Backed by expert R&D and precision manufacturing, we offer high-performance Vacuum, CVD, Muffle, Tube, and Rotary systems—all fully customizable to meet your specific temperature profiling and degassing requirements.

Ready to optimize your thermal processing? Contact our technical experts today to discover how our advanced laboratory furnaces can enhance your research and manufacturing outcomes.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What precaution should be taken before vacuum sintering to protect the vacuum system? Ensure Success with Proper De-binding

- What are some industrial applications of vacuum furnaces? Unlock Superior Material Performance

- What is the primary role of a vacuum resistance heating furnace in the TC4 titanium alloy brazing process?

- Why is a vacuum drying oven necessary before the electrochemical testing of sodium-ion battery electrodes? Optimize SIBs

- Why is the atmosphere control in Vacuum Furnaces essential? Unlock Precise High-Temperature Thermodynamic Insights

- What are the different types of crucible furnaces based on how molten metal is removed? A Guide to Lift-Out, Bale-Out, and Tilting Designs

- What are the benefits of vertical vacuum furnaces with gas pressure quenching? Achieve Superior Heat Treatment with Minimal Distortion

- What is the core function of a vertical vacuum furnace in purifying crude magnesium? Master Precision Vacuum Distillation