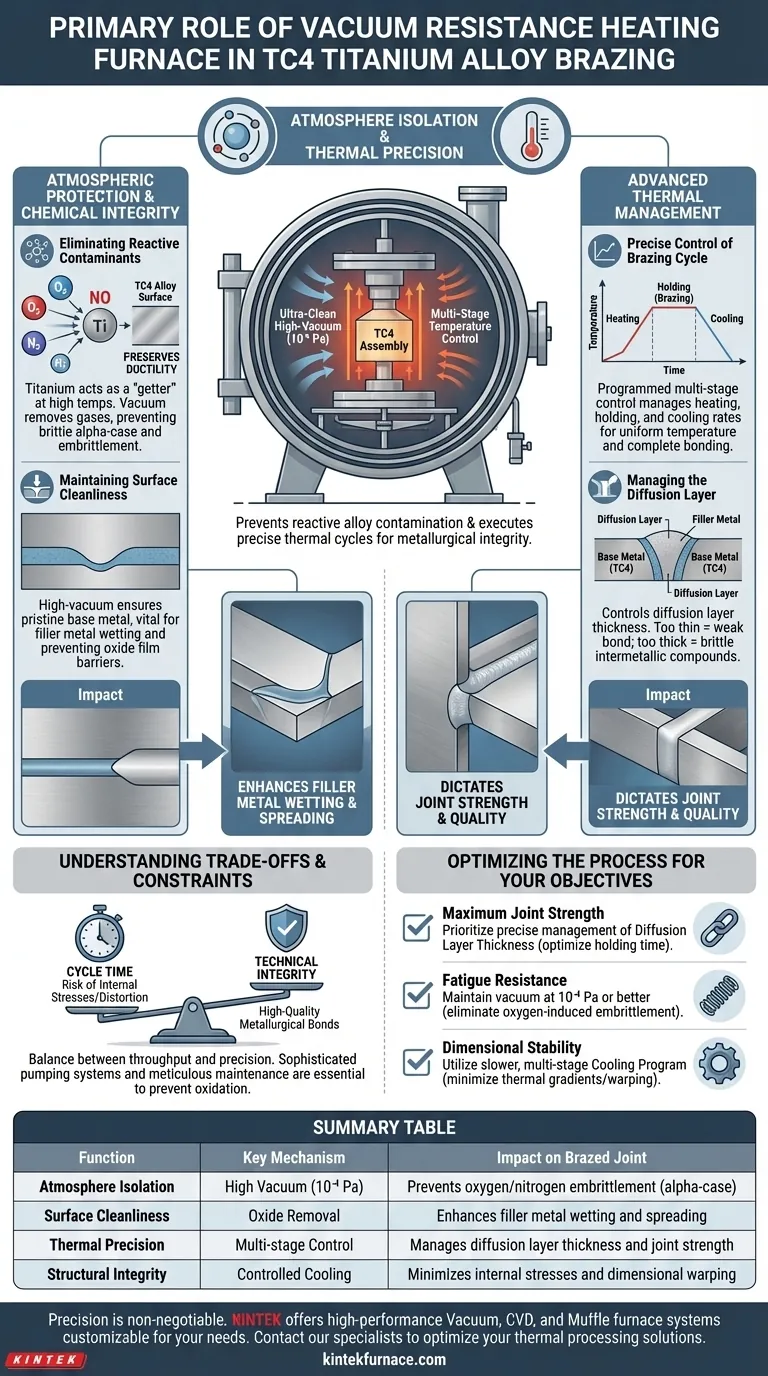

The vacuum resistance heating furnace serves two critical functions in TC4 titanium alloy brazing: atmosphere isolation and thermal precision. It creates an ultra-clean, high-vacuum environment (typically 10⁻⁴ Pa) to prevent titanium from reacting with atmospheric gases while providing the multi-stage temperature control necessary to manage the melting of filler metals and the growth of the diffusion layer.

The primary role of the furnace is to ensure metallurgical integrity by isolating the reactive TC4 alloy from contaminants that cause embrittlement, while simultaneously executing a precise thermal cycle that dictates the strength and quality of the brazed joint.

Atmospheric Protection and Chemical Integrity

Eliminating Reactive Contaminants

Titanium alloys like TC4 are extremely reactive at high temperatures, acting as a "getter" for oxygen, nitrogen, and hydrogen. If these gases are present during brazing, they dissolve into the titanium, creating a brittle surface layer known as an alpha-case. The vacuum furnace eliminates these gases, preventing material embrittlement and preserving the alloy's inherent ductility.

Maintaining Surface Cleanliness

A high-vacuum environment (typically around 10⁻⁴ Pa) ensures that the base metal surface remains pristine. This level of cleanliness is vital for the filler metal to wet and spread across the joint interface effectively. Without a high vacuum, oxide films would form instantly, acting as a barrier that prevents the filler metal from bonding with the TC4 substrate.

Advanced Thermal Management

Precise Control of the Brazing Cycle

Brazing requires heating the assembly to a specific point where the filler metal melts, but the base TC4 alloy remains solid. The furnace uses programmed multi-stage temperature control to manage heating, holding, and cooling rates. This precision ensures that the entire component reaches a uniform temperature, preventing localized overheating or incomplete bonding.

Managing the Diffusion Layer

The strength of a brazed joint depends on the diffusion layer—the zone where the filler and base metal atoms intermingle. The furnace's ability to hold specific temperatures for exact durations allows engineers to control the thickness of this layer. If the layer is too thin, the bond is weak; if it is too thick, brittle intermetallic compounds may form, compromising the joint's toughness.

Understanding the Trade-offs and Constraints

Cycle Time vs. Technical Integrity

Achieving a high-vacuum state and executing a multi-stage thermal cycle is a time-intensive process. While faster cooling might increase throughput, it risks introducing internal stresses or distorting the precision-engineered components. Engineers must balance the need for high-quality metallurgical bonds with the economic realities of long furnace cycles.

Equipment Sensitivity and Cost

Operating at 10⁻⁴ Pa requires sophisticated pumping systems and meticulous maintenance to prevent leaks. Any minor breach in the vacuum integrity during the heating cycle can lead to the oxidation of the entire batch. This high-stakes environment demands rigorous pre-brazing cleaning protocols and constant monitoring of furnace performance.

Optimizing the Process for Your Objectives

To achieve the best results with TC4 brazing, your operational parameters should align with the specific requirements of your end-use application.

- If your primary focus is maximum joint strength: Prioritize the precise management of the diffusion layer thickness by optimizing the holding time at the brazing temperature.

- If your primary focus is fatigue resistance: Ensure the vacuum level is maintained at 10⁻⁴ Pa or better to eliminate any trace of oxygen-induced embrittlement.

- If your primary focus is dimensional stability: Utilize a slower, multi-stage cooling program to minimize thermal gradients and prevent component warping.

The vacuum resistance furnace is not merely a heat source, but a sophisticated chemical and thermal reactor that defines the final mechanical properties of the TC4 assembly.

Summary Table:

| Function | Key Mechanism | Impact on Brazed Joint |

|---|---|---|

| Atmosphere Isolation | High Vacuum (10⁻⁴ Pa) | Prevents oxygen/nitrogen embrittlement (alpha-case) |

| Surface Cleanliness | Oxide Removal | Enhances filler metal wetting and spreading |

| Thermal Precision | Multi-stage Control | Manages diffusion layer thickness and joint strength |

| Structural Integrity | Controlled Cooling | Minimizes internal stresses and dimensional warping |

Precision is non-negotiable when brazing reactive alloys like TC4. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, CVD, and Muffle furnace systems customizable for your unique laboratory and industrial needs. Whether you require superior joint strength or fatigue resistance, our equipment delivers the exact thermal and atmospheric control you need to succeed. Contact our specialists today to optimize your thermal processing solutions.

Visual Guide

References

- Yibin Wu, Kun Liu. Effect of Brazing Temperature and Holding Time on the Interfacial Microstructure and Properties of TC4-Brazed Joints with Ti-Zr-Cu-Ni Amorphous Filler. DOI: 10.3390/ma18112471

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the applications of furnace brazing in the energy and power generation sector? Achieve Superior Joint Integrity for Critical Components

- What is Age Hardening in vacuum heat treating? Unlock Peak Metal Performance with Precision

- What is the core role of a vacuum resistance melting furnace in the vacuum refining process of AM60 magnesium alloy? Mastering Magnesium's Volatile Nature

- What is the difference between vacuum heat treatment and heat treatment? Achieve Superior Material Performance

- How does a vacuum environment help remove impurities from molten metal? Achieve High-Purity Metal for Superior Performance

- Why is a high-vacuum probe station necessary for SnS2 analysis? Ensure Pure Electrical Characterization

- What are the advantages of vacuum heat-treatment technology? Achieve Superior Material Quality and Precision

- What are the advantages of vacuum heat treatment? Achieve Superior Metallurgical Control and Pristine Surfaces