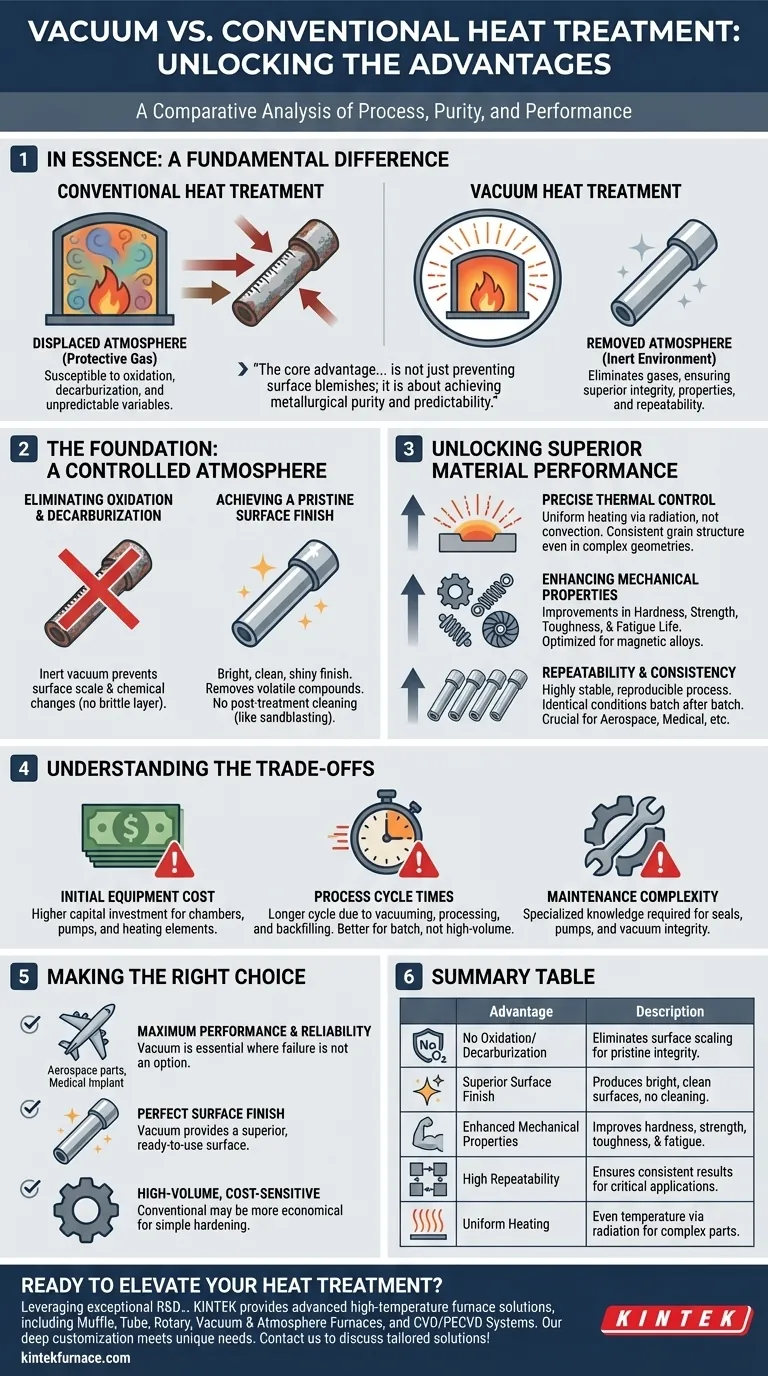

In essence, vacuum heat treatment provides a fundamentally more controlled environment than conventional methods, leading to superior surface integrity, enhanced material properties, and unmatched process repeatability. By removing atmospheric gases, the process eliminates unpredictable variables like oxidation and contamination, allowing for a level of precision that is often unachievable with traditional furnace atmospheres.

The core advantage of vacuum heat treatment is not just preventing surface blemishes; it is about achieving metallurgical purity and predictability. By operating in a near-perfect vacuum, you gain absolute control over the thermal process, ensuring the final component's properties meet design specifications without compromise.

The Foundation: A Controlled Atmosphere

Conventional heat treatment works by displacing the atmosphere with a protective gas. Vacuum heat treatment works by removing the atmosphere entirely. This fundamental difference is the source of its primary advantages.

Eliminating Oxidation and Decarburization

In a conventional furnace, the presence of oxygen, even in trace amounts, will cause oxidation (scaling) on the surface of the part. Similarly, carbon in the atmosphere can react with the steel, leading to unwanted carburization or decarburization, which alters the surface hardness and fatigue life.

A vacuum environment is inert. With no oxygen or reactive gases present, the part's surface chemistry remains unchanged, preserving its integrity and preventing the formation of a brittle, scaled layer.

Achieving a Pristine Surface Finish

Because there is no surface oxidation, parts emerge from a vacuum furnace with a bright, clean, and often shiny finish. This process also includes degassing and degreasing effects, as volatile compounds on the part's surface are vaporized and removed by the vacuum pump.

This eliminates the need for post-treatment cleaning operations like sandblasting or chemical pickling, saving time and reducing operational complexity.

Unlocking Superior Material Performance

The benefits of a vacuum environment extend beyond the surface, directly influencing the internal structure and final properties of the material.

The Power of Precise Thermal Control

Heating in a vacuum occurs primarily through radiation, eliminating the unpredictable nature of convection currents found in gas-filled furnaces. This allows for exceptionally uniform heating, ensuring the entire part, including complex geometries, reaches the target temperature at the same time.

This precise thermal management is critical for achieving a consistent and homogenous grain structure throughout the material, which is the key to predictable performance.

Enhancing Mechanical Properties

The combination of uniform heating and controlled cooling rates allows metallurgists to fine-tune the final properties with remarkable accuracy. This results in measurable improvements in hardness, strength, toughness, and fatigue life.

For specialized materials, such as magnetic alloys, the purity of the vacuum environment is essential for optimizing their magnetic properties.

Repeatability and Consistency

A vacuum furnace provides a highly stable and repeatable process. By removing atmospheric variables, every batch is processed under nearly identical conditions. This ensures that the first part produced has the same metallurgical properties as the thousandth.

This level of consistency is non-negotiable in critical industries like aerospace, medical, and high-performance manufacturing.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution. Objectivity requires acknowledging its limitations.

Initial Equipment Cost

Vacuum furnaces represent a significantly higher capital investment compared to most conventional atmospheric furnaces. The cost of the chamber, high-power heating elements, and sophisticated vacuum pump systems is substantial.

Process Cycle Times

Pulling a vacuum, processing the batch, and backfilling the chamber with a quenching gas can result in longer overall cycle times compared to some continuous, conventional heat treatment lines. This makes it better suited for batch production rather than high-volume, low-mix manufacturing.

Maintenance Complexity

Vacuum systems require specialized knowledge for maintenance. Seals, pumps, and internal fixtures must be meticulously maintained to ensure the integrity of the vacuum, which can lead to higher maintenance overhead compared to simpler atmospheric equipment.

Making the Right Choice for Your Application

The decision between vacuum and conventional heat treatment depends entirely on your final goal and the specific requirements of the component.

- If your primary focus is maximum performance and reliability: For aerospace components, medical implants, or high-performance tool steels where failure is not an option, the control and purity of vacuum treatment are essential.

- If your primary focus is a perfect surface finish: For parts where aesthetics are critical or where post-processing cleaning is undesirable, vacuum treatment provides a superior, ready-to-use surface.

- If your primary focus is high-volume, cost-sensitive production: For simple hardening of low-alloy steel components where minor scaling is acceptable, conventional heat treatment often remains the more economical choice.

Ultimately, choosing the right thermal process is about matching the tool to the specific metallurgical outcome you need to achieve.

Summary Table:

| Advantage | Description |

|---|---|

| No Oxidation/Decarburization | Eliminates surface scaling and chemical changes for pristine part integrity. |

| Superior Surface Finish | Produces bright, clean surfaces without post-treatment cleaning. |

| Enhanced Mechanical Properties | Improves hardness, strength, toughness, and fatigue life through precise control. |

| High Repeatability | Ensures consistent results batch after batch, ideal for aerospace and medical applications. |

| Uniform Heating | Uses radiation for even temperature distribution, perfect for complex geometries. |

Ready to elevate your heat treatment processes with precision and reliability? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, medical, or high-performance manufacturing, our expertise ensures superior metallurgical outcomes. Contact us today to discuss how our tailored solutions can benefit your specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision