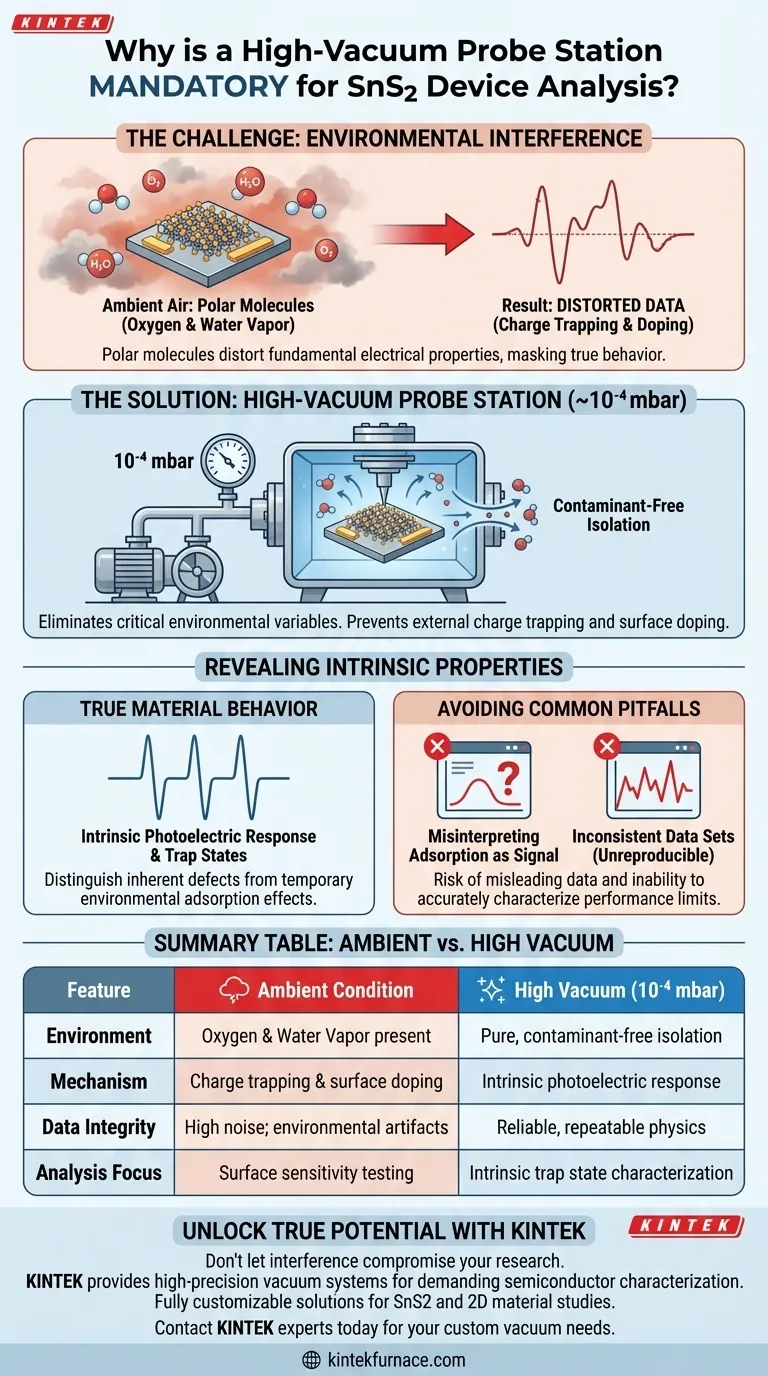

A high-vacuum probe station is a mandatory tool for the accurate electrical analysis of Tin Disulfide (SnS2) devices because it eliminates critical environmental variables. By operating at vacuum levels around 10^-4 mbar, the station removes polar molecules that otherwise distort the material's fundamental electrical properties.

By excluding oxygen and water vapor, high vacuum prevents external charge trapping and surface doping. This isolation enables researchers to distinguish the intrinsic photoelectric response of SnS2 from temporary environmental adsorption effects.

The Impact of Environmental Interference

The Culprits: Polar Molecules

The primary obstacles to accurate SnS2 analysis are environmental polar molecules.

Specifically, oxygen and water vapor present in ambient air are the main sources of interference.

Mechanisms of Distortion: Trapping and Doping

These molecules interact directly with the SnS2 surface.

This interaction leads to charge trapping and unintentional doping, which artificially alter the conductivity and responsiveness of the device.

Why High Vacuum is the Solution

Achieving the Correct Pressure

To effectively exclude these contaminants, the probe station must operate at specific vacuum levels.

The target pressure is approximately 10^-4 mbar, which is sufficient to strip the environment of interfering polar molecules.

Revealing Intrinsic Properties

The ultimate goal of using high vacuum is to observe the intrinsic photoelectric response of the material.

By removing the "noise" of environmental factors, researchers can clearly see the material's true behavior.

Isolating Trap States

Advanced analysis requires understanding the defects within the material itself.

Vacuum conditions allow you to distinguish between intrinsic trap states (inherent to the SnS2) and effects caused by external adsorption.

Common Pitfalls to Avoid

Misinterpreting Adsorption as Intrinsic Signal

If you analyze SnS2 in ambient air, you risk gathering misleading data.

A common error is attributing a specific electrical response to the material when it is actually caused by environmental adsorption.

Inconsistent Data Sets

Without vacuum control, fluctuations in humidity or oxygen levels can cause data inconsistency.

This makes it impossible to reproduce results or accurately characterize the device's performance limits.

Making the Right Choice for Your Goal

To ensure your research yields valid conclusions, align your testing environment with your specific objectives.

- If your primary focus is determining material physics: You must use high vacuum (10^-4 mbar) to measure intrinsic trap states without interference from oxygen or water.

- If your primary focus is characterizing surface sensitivity: You may compare vacuum measurements against ambient measurements to quantify the specific impact of environmental doping.

Using a high-vacuum environment is the only way to validate the true electrical identity of your SnS2 device.

Summary Table:

| Feature | Ambient Condition | High Vacuum (10^-4 mbar) |

|---|---|---|

| Environment | Oxygen & Water Vapor present | Pure, contaminant-free isolation |

| Mechanism | Charge trapping & surface doping | Intrinsic photoelectric response |

| Data Integrity | High noise; environmental artifacts | Reliable, repeatable physics |

| Analysis Focus | Surface sensitivity testing | Intrinsic trap state characterization |

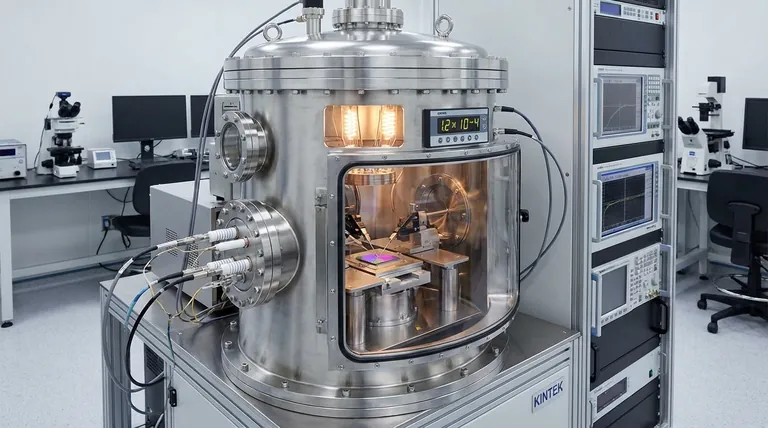

Unlock the True Potential of Your Semiconductor Materials

Don't let environmental interference compromise your research. KINTEK provides high-precision lab solutions, including advanced vacuum systems tailored for the most demanding semiconductor characterization. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique needs of your SnS2 and 2D material studies.

Ready to achieve high-vacuum precision in your lab?

Contact KINTEK experts today to discuss your custom furnace or vacuum needs.

Visual Guide

References

- S. De Stefano, Antonio Di Bartolomeo. Neuromorphic Photoresponse in Ultrathin SnS<sub>2</sub>-Based Field Effect Transistor. DOI: 10.1021/acsami.5c11651

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What applications does a vacuum melting furnace have in research? Unlock High-Purity Material Development

- Why is a vacuum oven essential for photocatalyst preparation? Ensure Nanostructural Integrity and Purity

- Why is a vacuum deposition system required for BL-MoS2 doping? Achieve Nanogram-Level Precision & Purity

- What temperature is vacuum brazing? Achieve Strong, Flux-Free Joints in a Controlled Environment

- What is vacuum heat treatment and why is it important in mechanical manufacturing? Boost Component Performance and Lifespan

- What role does graphite fixturing play in the heat treatment of steel aerospace components? Ensure Precision and Minimize Distortion

- Why is the use of a vacuum drying oven critical during LSC oxygen electrode modification? Achieve Deep Impregnation

- What are the key characteristics of high-temperature vacuum furnaces? Achieve Ultimate Purity and Precision in Material Processing