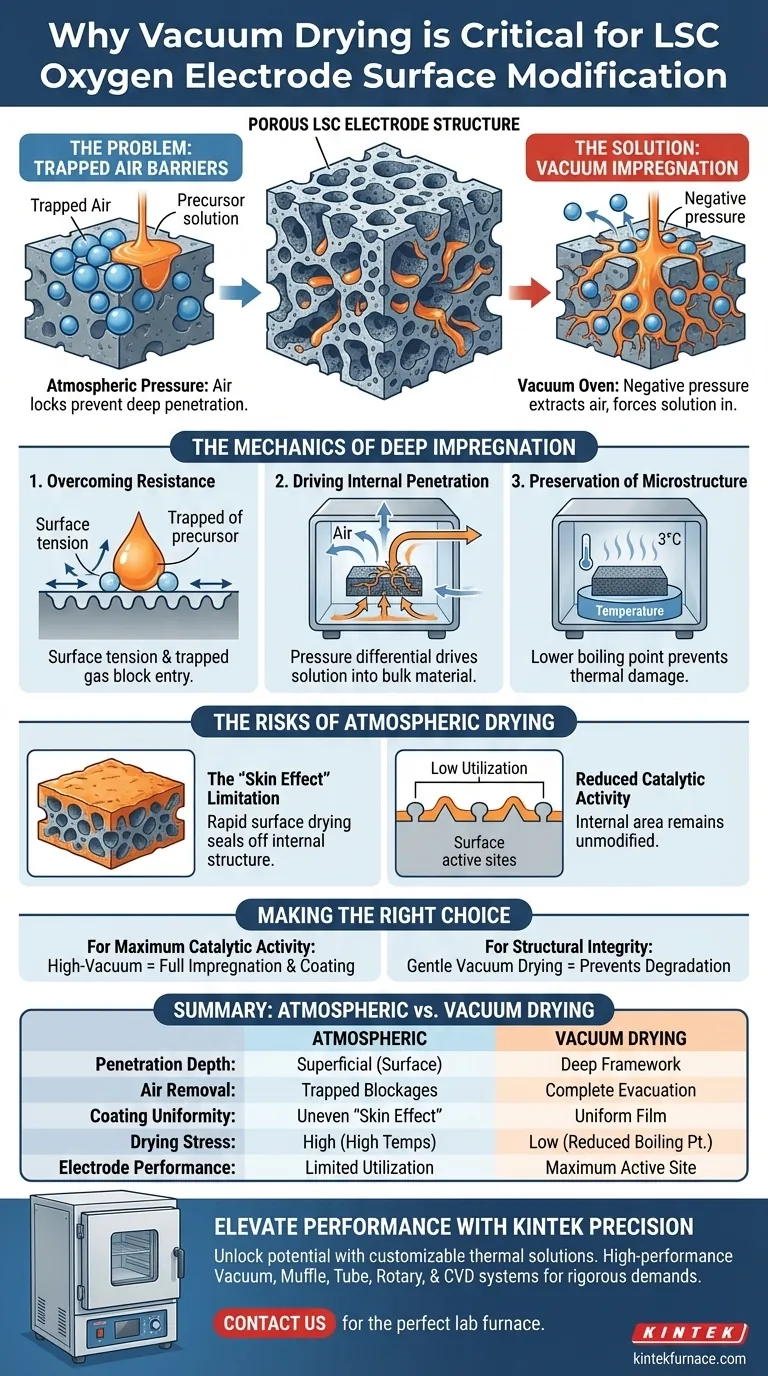

The application of a vacuum drying oven is fundamental to overcoming the physical barriers within porous electrode structures. It utilizes negative pressure to force the precursor solution deep into the complex LSC (Lanthanum Strontium Cobaltite) framework. This process evacuates trapped air that would otherwise block the liquid, ensuring the modification occurs throughout the entire internal volume rather than just on the exterior.

By actively removing air locks within the porous material, vacuum treatment transforms surface modification from a superficial coating process into a deep impregnation method, guaranteeing that nano-catalytic films are distributed uniformly throughout the electrode's active sites.

The Mechanics of Deep Impregnation

Overcoming Hydraulic Resistance

The porous structure of an LSC oxygen electrode is naturally resistant to liquid penetration due to surface tension and trapped gases.

When you apply a precursor solution under normal atmospheric conditions, air pockets remain lodged deep within the micropores.

A vacuum drying oven creates a negative pressure environment that physically extracts this trapped air, creating a void that the liquid precursor must fill.

Driving Internal Penetration

Once the air is evacuated, the pressure differential drives the precursor solution into the deepest layers of the electrode framework.

This ensures that the active material is not merely painted onto the surface but is impregnated into the bulk of the material.

This deep penetration is the mechanism that allows for the formation of a uniform nano-catalytic film across the entire internal surface area.

Preservation of Microstructure

Beyond impregnation, vacuum drying facilitates the removal of solvents at lower temperatures by reducing their boiling points.

This gentle evaporation prevents thermal stress or structural damage that might occur if high heat were used to force-dry the deep pores.

It ensures the electrode maintains its intricate porous architecture, which is vital for gas diffusion during operation.

The Risks of Atmospheric Drying

The "Skin Effect" Limitation

Without vacuum assistance, the precursor solution often dries rapidly on the outermost surface of the electrode.

This creates a "skin" or crust that blocks the underlying pores, effectively sealing off the internal structure from modification.

Reduced Catalytic Activity

If the precursor remains on the surface, the vast majority of the electrode's internal surface area remains unmodified and catalytically inactive.

This results in an electrode that theoretically has high potential but performs poorly in practice due to low utilization of the added catalyst.

Making the Right Choice for Your Goal

To maximize the performance of LSC oxygen electrodes, the drying process must be treated as an active impregnation step, not just a passive removal of liquid.

- If your primary focus is Maximum Catalytic Activity: Prioritize high-vacuum levels to fully evacuate micropores, ensuring every internal surface is coated with the nano-catalyst.

- If your primary focus is Structural Integrity: Use the vacuum to lower the boiling point of solvents, allowing for gentle drying that prevents thermal degradation of the LSC framework.

Vacuum drying is not merely a method of evaporation; it is the primary engine for achieving total structural utilization in porous electrodes.

Summary Table:

| Feature | Atmospheric Drying | Vacuum Drying Oven |

|---|---|---|

| Penetration Depth | Superficial (Surface Only) | Deep Framework Impregnation |

| Air Removal | Trapped gas creates blockages | Complete evacuation of micropores |

| Coating Uniformity | Uneven "Skin Effect" | Uniform nano-catalytic film |

| Drying Stress | High (Requires higher temps) | Low (Reduced solvent boiling point) |

| Electrode Performance | Limited catalytic utilization | Maximum active site utilization |

Elevate Your Electrode Performance with KINTEK Precision

Unlock the full potential of your porous materials with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems—all fully customizable to meet the rigorous demands of your surface modification and impregnation workflows.

Don't let trapped air limit your research. Our vacuum drying technology ensures uniform nano-catalytic distribution and preserves the delicate microstructure of your LSC frameworks. Contact us today to find the perfect customizable furnace for your lab and take the first step toward superior catalytic efficiency.

Visual Guide

References

- Binbin Liu, Tao Li. Pr<sub>2</sub>Ni<sub>0.8</sub>Co<sub>0.2</sub>O<sub>4+<i>δ</i></sub> impregnated La<sub>0.6</sub>Sr<sub>0.4</sub>CoO<sub>3−<i>δ</i></sub> oxygen electrode for efficient CO<sub>2</sub> electroreduction in solid oxide electrolysis cells. DOI: 10.1039/d4ra01848f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does vacuum heat treatment work? Achieve Cleaner, Stronger Materials with Precision

- Why is a vacuum oven utilized for drying NaFePO4 gel? Prevent Oxidation and Ensure Chemical Homogeneity

- What role do laboratory arc furnaces and tungsten electrodes play in TiCo1-xCrxSb synthesis? Expert Material Analysis

- What is the significance of using a vacuum annealing furnace for zirconium sponge? Ensure Purity and Process Stability

- How does a vacuum furnace prevent oxidation of the workpiece? Achieve Purity and Precision in High-Temp Processing

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C

- How does vacuum heat treatment enhance product quality? Achieve Superior Material Integrity and Performance

- How does vacuum brazing work? Achieve Superior Joint Integrity for Critical Applications