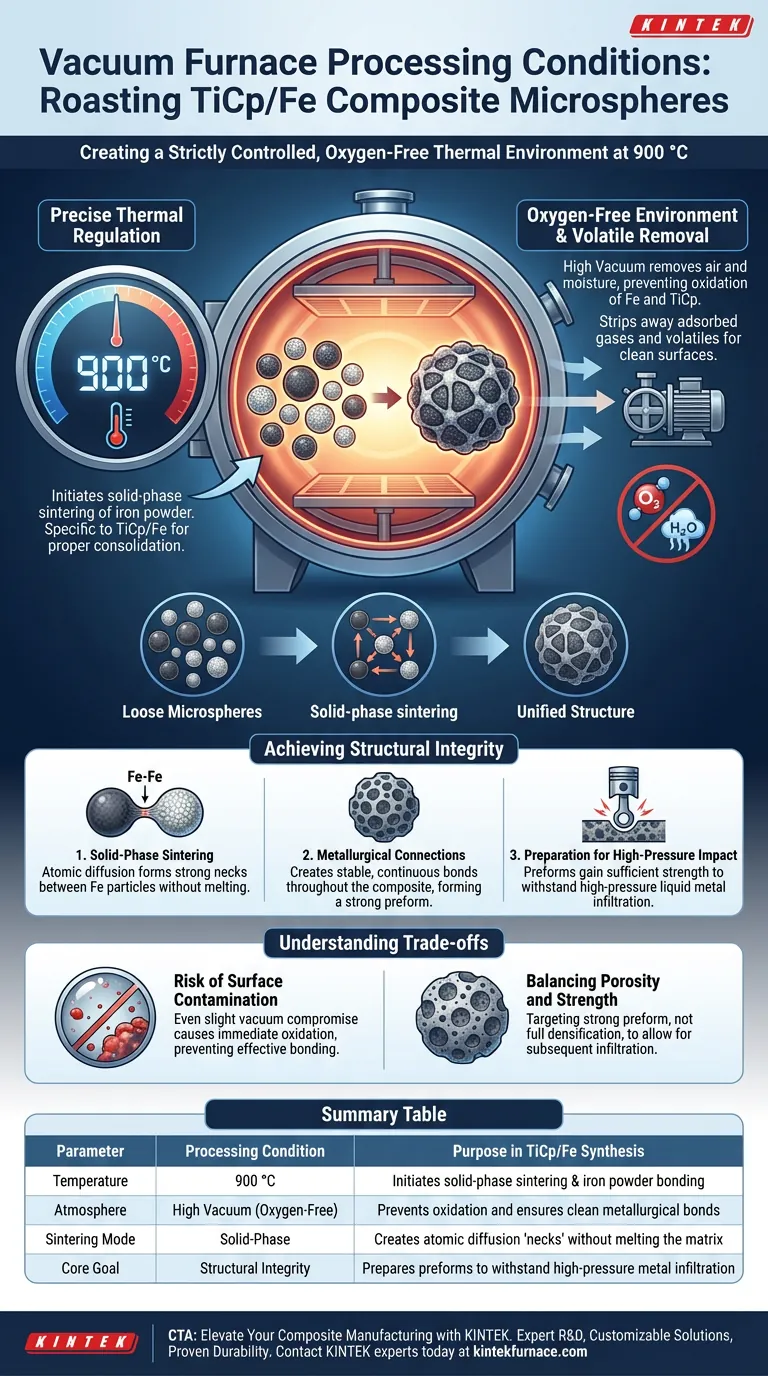

During the roasting of TiCp/Fe composite microspheres, a vacuum furnace provides a strictly controlled, oxygen-free thermal environment maintained at 900 °C. This specific condition is critical for facilitating the solid-phase sintering of iron powder without the detrimental effects of oxidation. The process converts loose microspheres into a unified structure with stable metallurgical connections.

Core Takeaway: The vacuum furnace does not simply heat the material; it creates a pristine environment that enables solid-phase sintering at 900 °C. This strengthens the preforms significantly, allowing them to withstand the intense impact of subsequent high-pressure liquid metal infiltration.

The Critical Processing Conditions

Precise Thermal Regulation

The primary function of the furnace during this phase is to maintain a roasting temperature of 900 °C.

At this temperature, the iron powder within the composite reaches the necessary energy state to initiate bonding. This thermal treatment is specific to the requirements of the TiCp/Fe materials to ensure proper consolidation.

Oxygen-Free Environment

The vacuum aspect of the furnace creates an oxygen-free atmosphere.

By evacuating air and moisture, the furnace prevents the iron (Fe) and titanium carbide (TiCp) components from oxidizing. Removing oxygen is essential because oxide layers act as barriers that inhibit atomic diffusion and weaken particle bonding.

Removal of Volatiles

While the primary goal is preventing oxidation, the vacuum environment also actively cleans the material surfaces.

Drawing on general vacuum processing principles, this low-pressure environment helps strip away adsorbed gases and volatiles from the powder surfaces. This ensures that the contact points between microspheres are chemically clean, further promoting effective sintering.

Achieving Structural Integrity

Solid-Phase Sintering

The 900 °C vacuum environment facilitates solid-phase sintering of the iron powder.

Unlike liquid-phase sintering where melting occurs, this process relies on atomic diffusion between particles in a solid state. The iron particles bond together at their contact points, creating "necks" that connect the microspheres.

Formation of Metallurgical Connections

The ultimate goal of this thermal treatment is the formation of stable metallurgical connections.

The clean, high-temperature environment ensures that these bonds are strong and continuous throughout the composite. This transforms the individual microspheres into a cohesive, porous preform.

Preparation for High-Pressure Impact

The mechanical strength gained during this roasting phase is not an end in itself, but a preparation for the next manufacturing step.

The preforms must attain sufficient strength to withstand the impact force of high-pressure liquid metal infiltration. Without the robust sintering provided by the vacuum roast, the preform would likely collapse or deform during the infiltration process.

Understanding the Trade-offs

The Risk of Surface Contamination

If the vacuum integrity is compromised even slightly, oxidation will occur immediately at 900 °C.

Oxides are generally brittle and prevent the iron matrix from wetting and bonding effectively with the reinforcement phases. The trade-off for high-performance sintering is the absolute necessity of maintaining a high-quality vacuum; a poor vacuum is often worse than no vacuum in high-temperature metallurgy.

Balancing Porosity and Strength

The process aims to sinter the particles for strength, but not to fully densify them into a solid block yet.

The goal is to create a strong preform, which implies that interconnected porosity must remain to allow for the subsequent liquid metal infiltration. Over-sintering (too high temperature or too long) could close off pores, while under-sintering leads to structural failure during infiltration.

Making the Right Choice for Your Goal

To maximize the quality of TiCp/Fe composite microspheres, align your process controls with your specific manufacturing stage:

- If your primary focus is Structural Integrity: Ensure the furnace consistently maintains 900 °C to guarantee complete solid-phase sintering of the iron powder.

- If your primary focus is Process Reliability: Prioritize the vacuum quality to prevent oxide formation, which is the leading cause of weak metallurgical connections.

- If your primary focus is Subsequent Processing: Verify that the roasted preforms have achieved enough mechanical strength to survive high-pressure infiltration without collapsing.

The vacuum furnace acts as the foundational tool that transforms raw powder into a robust preform capable of enduring aggressive downstream processing.

Summary Table:

| Parameter | Processing Condition | Purpose in TiCp/Fe Synthesis |

|---|---|---|

| Temperature | 900 °C | Initiates solid-phase sintering & iron powder bonding |

| Atmosphere | High Vacuum (Oxygen-Free) | Prevents oxidation and ensures clean metallurgical bonds |

| Sintering Mode | Solid-Phase | Creates atomic diffusion 'necks' without melting the matrix |

| Core Goal | Structural Integrity | Prepares preforms to withstand high-pressure metal infiltration |

Elevate Your Composite Manufacturing with KINTEK

Precision at 900 °C requires more than just heat—it requires a contamination-free environment. KINTEK provides industry-leading Vacuum, Tube, and CVD systems designed to meet the rigorous demands of TiCp/Fe composite roasting and solid-phase sintering.

Our Value to You:

- Expert R&D: Systems engineered for stable metallurgical connections and uniform thermal regulation.

- Customizable Solutions: Tailored furnace configurations to balance porosity and structural strength for your specific preform needs.

- Proven Durability: Robust manufacturing ensures consistent vacuum integrity to eliminate oxidation risks.

Ready to optimize your lab's high-temperature processing? Contact KINTEK experts today to find the perfect customizable furnace for your unique research goals.

Visual Guide

References

- Shengnian Zhao, Yehua Jiang. Microstructure and Properties of TiCp/Fe Hierarchical Composites Prepared by a New Pressure Infiltration Method. DOI: 10.3390/ma17061325

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- What is the role of the heat exchanger in vacuum gas quenching? Optimize Cooling Intensity & Metal Hardness

- What are the advantages of vacuum heat treatment? Achieve Superior Cleanliness and Performance for Critical Parts

- What are the key components of a vacuum pressure sintering furnace? Essential Systems for High-Performance Materials

- How does the heating mechanism of an SPS furnace benefit CNT copper composites? Preserve Nanostructures with Rapid Heat

- Why is the precise control of H2 and C2H2 flow rates essential in plasma carburizing of AISI 316L? Master the S-Phase

- What materials are compatible with high vacuum furnaces? Essential Guide for Aerospace, Medical, and Electronics

- How does a high-temperature vacuum contact angle system study Al 7075 alloys? Mastering Surface Tension & Oxidation