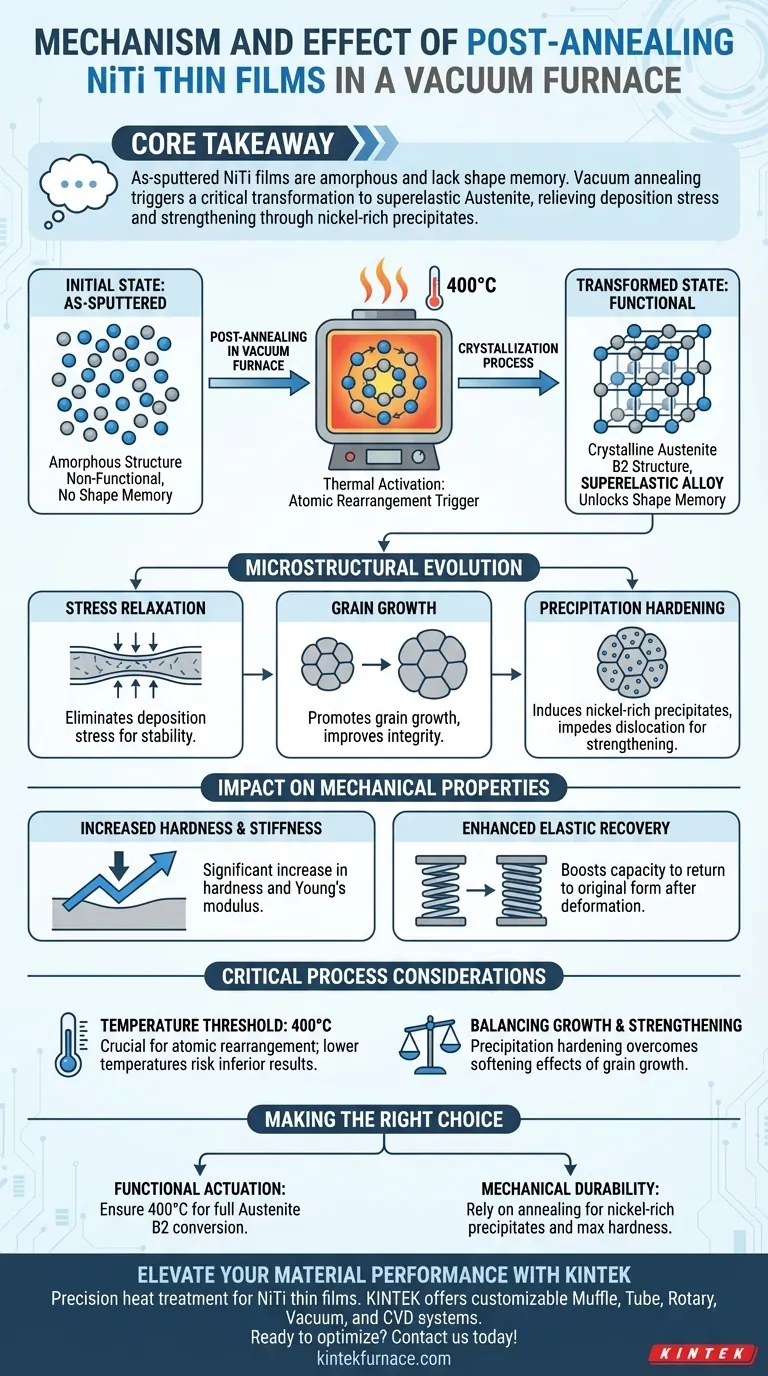

Post-annealing NiTi (Nickel-Titanium) thin films in a vacuum furnace is the mandatory activation step required to transform the material from a non-functional state into a superelastic alloy. Initially deposited films are amorphous; annealing at 400 °C provides the thermal energy necessary to rearrange atoms into a crystalline Austenite B2 structure, which unlocks the shape memory effect and enhances mechanical strength.

Core Takeaway As-sputtered NiTi films are amorphous and lack shape memory properties. Vacuum annealing triggers a critical phase transformation to superelastic Austenite, simultaneously relieving deposition stress and strengthening the material through the formation of nickel-rich precipitates.

The Mechanism of Crystallization

Overcoming the Amorphous State

When NiTi thin films are initially deposited via sputtering, their atomic structure is amorphous. In this disordered state, the material does not exhibit the shape memory effect or superelasticity.

Thermal Activation

Post-annealing acts as a thermal trigger. By subjecting the film to high-temperature heat treatment—specifically at 400 °C—you provide the system with sufficient energy to induce atomic rearrangement.

Formation of the Austenite B2 Phase

This energy input allows the atoms to snap into an ordered crystalline lattice. This process transforms the amorphous structure into the superelastic Austenite B2 phase, which is the prerequisite for the functional properties of Nitinol.

Microstructural Evolution

Stress Relaxation

The deposition process naturally introduces internal stresses within the film. Vacuum furnace annealing effectively eliminates this deposition stress, resulting in a more stable material.

Grain Growth

The heat treatment promotes grain growth. As the crystalline grains enlarge and stabilize, the overall structural integrity of the film improves.

Precipitation Hardening

A critical microstructural change during this process is the induction of nickel-rich precipitates. These precipitates impede dislocation movement, directly contributing to the mechanical strengthening of the film.

Impact on Mechanical Properties

Increased Hardness and Stiffness

Due to the combined effects of crystallization and precipitation, the mechanical robustness of the film increases significantly. The process enhances both hardness and Young's modulus (stiffness).

Enhanced Elastic Recovery

The defining characteristic of processed NiTi is its ability to recover its shape. The formation of the Austenite B2 phase significantly boosts the elastic recovery capacity, allowing the film to return to its original form after deformation.

Critical Process Considerations

The Temperature Threshold

Success depends on reaching specific energy levels. The reference highlights 400 °C as the critical temperature required to activate the atomic rearrangement. Failing to reach this threshold may leave the film partially amorphous and mechanically inferior.

Balancing Growth and Strengthening

While annealing promotes grain growth, which typically softens materials, this is counterbalanced by the formation of nickel-rich precipitates. It is crucial to understand that the enhanced hardness and modulus described are a result of this precipitation overcoming the softening effects of grain growth.

Making the Right Choice for Your Goal

When integrating NiTi thin films into your application, use the annealing process to tailor performance:

- If your primary focus is Functional Actuation: Ensure your heat treatment reaches 400 °C to fully convert the amorphous structure into the superelastic Austenite B2 phase.

- If your primary focus is Mechanical Durability: Rely on vacuum annealing to induce nickel-rich precipitates, which are essential for maximizing hardness and Young's modulus.

Ultimate Success: To transition NiTi from a passive coating to an active functional material, you must prioritize vacuum annealing to drive the atomic organization and precipitation hardening that define superelasticity.

Summary Table:

| Process Element | Effect on NiTi Thin Film |

|---|---|

| Phase Change | Amorphous state transforms into crystalline Austenite B2 phase |

| Thermal Energy | 400 °C threshold required for atomic rearrangement |

| Stress Relief | Eliminates internal deposition stresses for higher stability |

| Microstructure | Induces nickel-rich precipitates and promotes grain growth |

| Mechanical Impact | Significant increase in hardness, Young's modulus, and elastic recovery |

Elevate Your Material Performance with KINTEK

Precision heat treatment is the key to transforming NiTi thin films into high-performance superelastic alloys. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory and production needs.

Whether you are focusing on functional actuation or mechanical durability, our high-temperature furnaces provide the uniform heating and vacuum stability required for critical crystallization and precipitation hardening.

Ready to optimize your NiTi thin film processing? Contact us today to find the perfect furnace solution!

Visual Guide

References

- André V. Fontes, Ana Sofia Ramos. Exploring the Influence of the Deposition Parameters on the Properties of NiTi Shape Memory Alloy Films with High Nickel Content. DOI: 10.3390/coatings14010138

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do industrial-grade vacuum furnaces refine grain and relieve stress in Inconel 718? Achieve Peak Superalloy Strength

- What are the key functions of a high-vacuum high-temperature testing machine? Evaluate UHTCMC Mechanical Reliability

- How do vacuum furnaces contribute to the production of advanced ceramic materials? Achieve Superior Purity and Density

- What are the advantages of vacuum heat treatment? Achieve Superior Metallurgical Control and Pristine Surfaces

- What is the function of a high-pressure stainless steel autoclave in hydrothermal carbonization? Unlock Superior Carbon

- How do heat treatment and vacuum furnaces contribute to industrial innovation? Unlock Superior Material Performance

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- What is the working principle of a vacuum furnace? Achieve High-Purity Heat Treatment for Sensitive Materials