A high-vacuum high-temperature testing machine serves the critical function of isolating mechanical performance from chemical degradation during material evaluation. It is designed to subject Ultra-High Temperature Ceramic Matrix Composites (UHTCMCs) to thermal loads exceeding 900°C while maintaining a strict oxygen-free vacuum. This dual-capability ensures that the data collected reflects the material's true structural capabilities without the interference of environmental factors like oxidation.

By simulating the extreme heat of hypersonic flight while eliminating oxygen, this technology separates thermal stress from chemical reaction. This isolation is the only way to determine the actual mechanical baseline—specifically flexural strength and elastic modulus—of composites intended for aerospace applications.

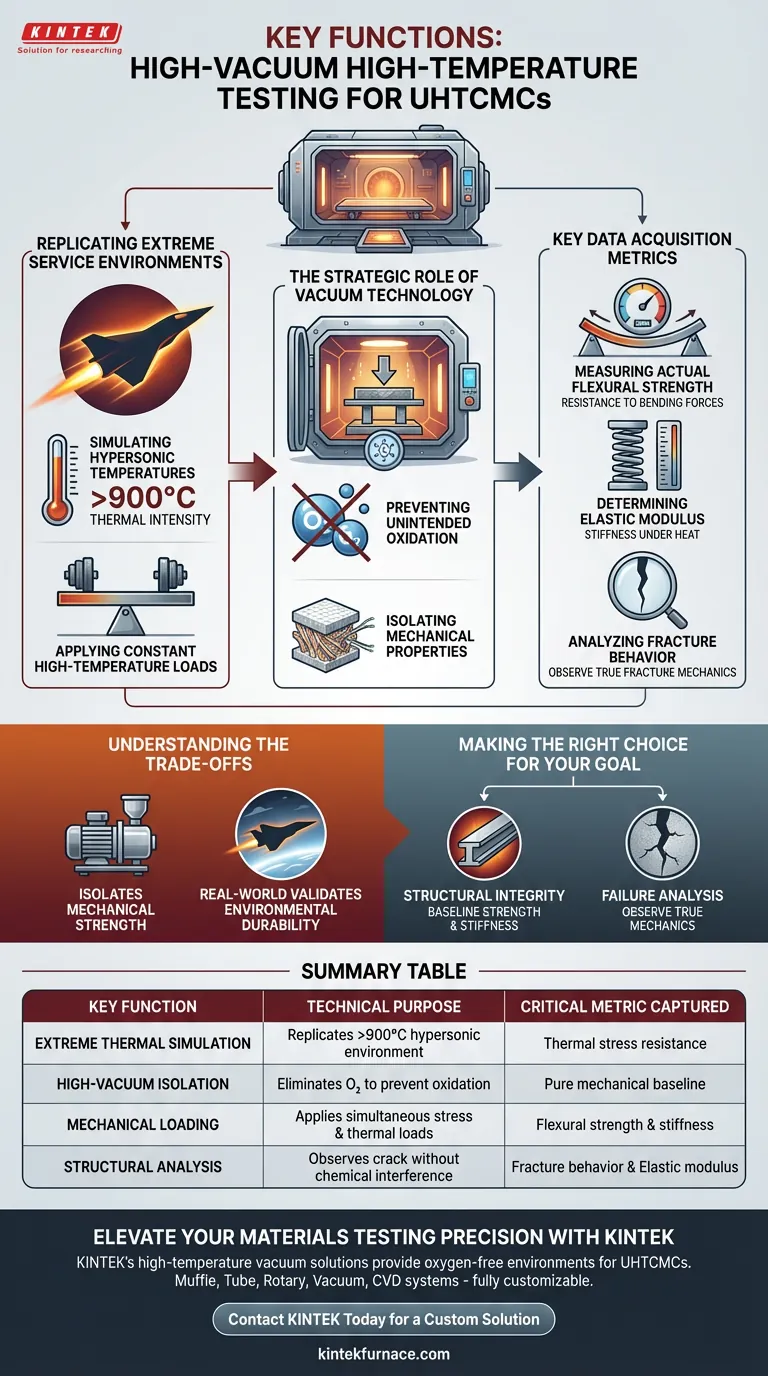

Replicating Extreme Service Environments

The primary challenge in testing UHTCMCs is reproducing the harsh conditions of operation without introducing uncontrolled variables.

Simulating Hypersonic Temperatures

The machine is capable of generating and sustaining temperatures of 900°C or higher. This thermal intensity is necessary to mimic the service environment faced by hypersonic aircraft components during flight.

Applying Constant High-Temperature Loads

Beyond simple heating, the machine provides a consistent load environment. It applies mechanical stress simultaneously with thermal stress to test how the material bears weight under extreme heat.

The Strategic Role of Vacuum Technology

High temperatures typically accelerate chemical reactions, which can skew test results. The vacuum system is the countermeasure to this problem.

Preventing Unintended Oxidation

At high temperatures, the carbon fibers and ceramic matrices within UHTCMCs are highly susceptible to oxidation. The vacuum system creates an oxygen-free environment to completely halt this process.

Isolating Mechanical Properties

By preventing oxidation, the machine ensures that the test measures the material's mechanics rather than its chemistry. It protects the integrity of the fibers and matrix so that failure is caused by load and heat, not by the material burning away.

Key Data Acquisition Metrics

The ultimate goal of this testing setup is the acquisition of "clean" data that accurately represents the material's reliability.

Measuring Actual Flexural Strength

Because the material remains chemically intact, engineers can determine its actual flexural strength. This figure represents the material's resistance to bending forces in its pure state.

Determining Elastic Modulus

The machine allows for the precise calculation of the elastic modulus (stiffness) under heat. This metric is vital for understanding how much the component will deform during hypersonic flight.

Analyzing Fracture Behavior

Testing in a vacuum allows for the observation of fracture behavior driven purely by mechanical stress. This helps engineers understand how the material cracks or fails structurally, unclouded by surface degradation.

Understanding the Trade-offs

While this testing method is superior for mechanical characterization, it is important to understand what it excludes.

The Limitation of "Perfect" Environments

Testing in a vacuum removes the variable of oxidation to isolate mechanical strength. However, real-world atmospheric flight does involve oxygen. Therefore, this testing validates the structure but does not test the material's lifespan in oxygen-rich air. It is a test of strength, not environmental durability.

Making the Right Choice for Your Goal

When designing a testing protocol for UHTCMCs, clarity on your specific data requirements is essential.

- If your primary focus is Structural Integrity: Use this machine to establish the baseline flexural strength and stiffness of the material without the noise of chemical degradation.

- If your primary focus is Failure Analysis: Rely on the vacuum environment to observe true fracture mechanics, ensuring that cracks are driven by stress and temperature rather than oxidation embrittlement.

This machine is the definitive tool for proving that a composite is mechanically capable of surviving the thermal rigors of hypersonic travel.

Summary Table:

| Key Function | Technical Purpose | Critical Metric Captured |

|---|---|---|

| Extreme Thermal Simulation | Replicates environments >900°C for hypersonic flight simulation | Thermal stress resistance |

| High-Vacuum Isolation | Eliminates oxygen to prevent material oxidation/degradation | Pure mechanical baseline |

| Mechanical Loading | Applies stress simultaneously with thermal loads | Flexural strength & stiffness |

| Structural Analysis | Observes crack propagation without chemical interference | Fracture behavior & Elastic modulus |

Elevate Your Materials Testing Precision with KINTEK

Don't let oxidation skew your critical data. KINTEK’s high-temperature vacuum solutions provide the oxygen-free environments necessary to isolate pure mechanical reliability in UHTCMCs and aerospace composites. Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique testing requirements.

Ready to achieve the structural baseline your project demands?

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Luis Baier, Vito Leisner. Development of ultra-high temperature ceramic matrix composites for hypersonic applications via reactive melt infiltration and mechanical testing under high temperature. DOI: 10.1007/s12567-024-00562-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What roles do vacuum furnaces and pulse power supplies play in plasma nitriding? Enhance Steel Hardening & Uniformity

- How does the annealing process in a high-temperature furnace modify MoS2? Optimize Thermoelectric Performance

- What are the key applications of laboratory vacuum furnaces? Unlock High-Purity Material Processing

- What is the temperature of a vacuum brazing furnace? Precision Heat for Flawless Metal Joining

- What is the purpose of using a vacuum drying oven? Ensure Accurate Powder Characterization and Material Integrity

- What are the differences between hot wall and cold wall vacuum furnace designs? Compare for Your High-Temp Needs

- What is the typical shape of heating elements in vacuum furnaces and why? Optimize Heat Transfer for Your Application

- What are the common types of materials used for constructing heating elements in electrically heated vacuum furnaces? Choose the Right Material for Your Process