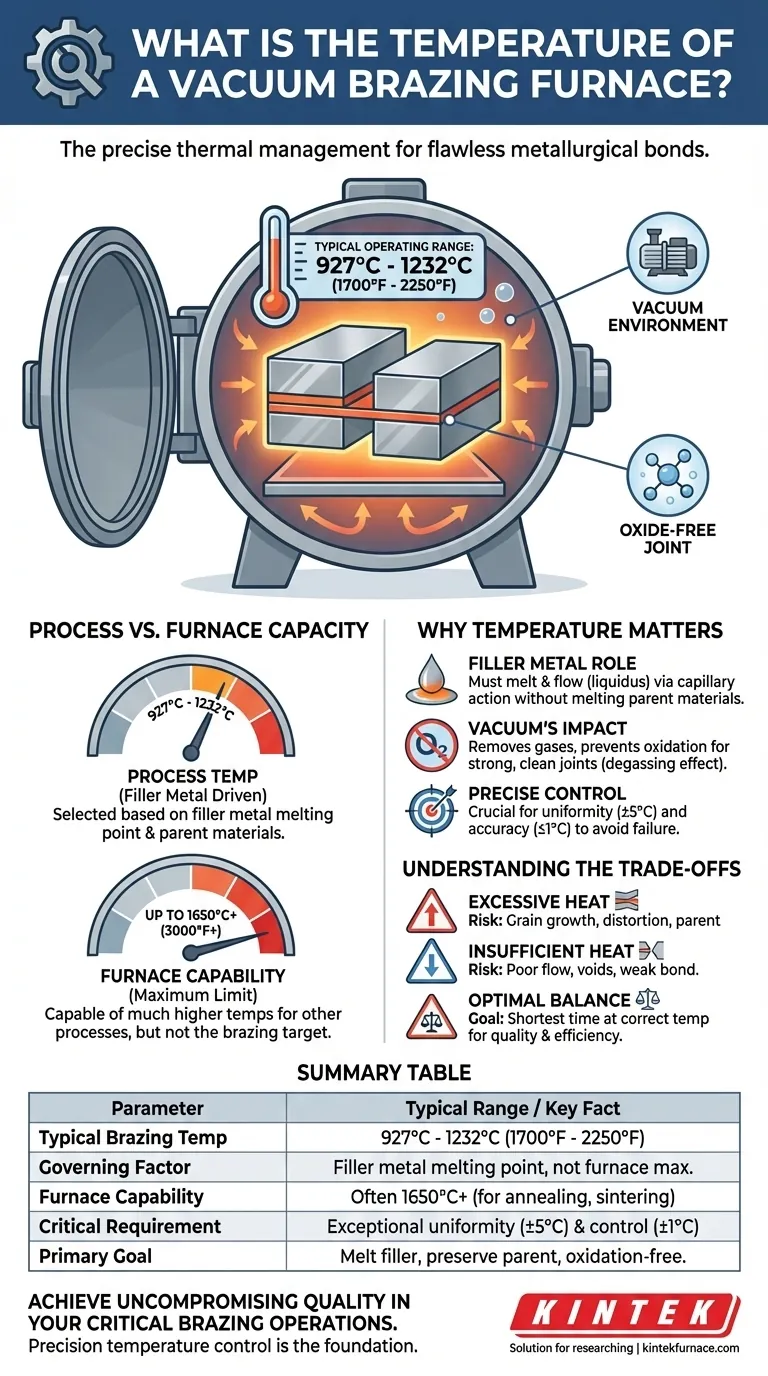

The typical operating temperature for a vacuum brazing furnace is between 927°C and 1232°C (1700°F - 2250°F). This range is not a fixed limit of the equipment but is carefully selected based on the specific parent materials being joined and the melting point of the filler metal used to create the bond. The furnace itself is capable of reaching much higher temperatures, but the process dictates the precise heat required.

The temperature in vacuum brazing is not about reaching the furnace's maximum heat. It is a precisely controlled variable engineered to melt a specific filler metal without damaging the core materials, all within a pure vacuum environment that guarantees a flawless, oxide-free joint.

Why Temperature is the Core of the Brazing Process

The success of any brazing operation hinges on precise thermal management. The temperature profile is carefully engineered to achieve a specific metallurgical outcome.

The Role of the Filler Metal

Brazing joins two parent materials using a dissimilar filler metal. This filler metal is designed to have a lower melting point than the materials it is joining.

The goal is to heat the entire assembly to a temperature that is above the filler metal's melting point but safely below the melting point of the parent materials.

At this temperature, the filler metal becomes liquid and, through capillary action, is drawn into the tight-fitting gap between the parent materials. Upon cooling, it solidifies and forms a strong, permanent metallurgical bond.

Selecting the Brazing Temperature

The specific brazing temperature is chosen to be slightly above the liquidus temperature of the chosen filler alloy—the point at which it becomes fully liquid.

This ensures the filler metal flows freely and completely wets the surfaces of the joint. Common filler metals for vacuum brazing include nickel-based alloys, pure copper, and precious metal alloys, each with its own unique melting characteristics.

The Impact of a Vacuum Environment

Performing this process in a vacuum is critical. The vacuum removes atmospheric gases like oxygen, creating an ultra-pure, oxidation-free environment.

This prevents the formation of oxides on the metal surfaces, which would otherwise inhibit the flow of the filler metal and weaken the final joint. The vacuum also has a degassing effect, pulling trapped gases out of the metals to improve the final joint's hardness and quality.

Furnace Capability vs. Process Temperature

It is essential to distinguish between the temperature required for the brazing process and the maximum temperature the furnace can achieve.

Typical Operating Range

As stated, most vacuum brazing of common alloys like steel and superalloys occurs between 927°C and 1232°C. This window covers the melting points for the vast majority of high-strength nickel and copper-based filler metals.

Maximum Furnace Temperature

A modern vacuum furnace is a highly capable piece of equipment. Depending on its design and series, it may be able to reach temperatures of 1650°C (3000°F), 2000°C (3632°F), or even higher.

This high-end capability provides a wide operational margin and allows the furnace to be used for other thermal processes like annealing or sintering, but it is not the target for most brazing cycles.

The Importance of Precise Control

The true value of a vacuum furnace is not just its peak heat, but its precision. These systems offer exceptional temperature uniformity (often ±5°C) across the entire workload.

Furthermore, with advanced PID loop controls, they can maintain a setpoint with extreme accuracy, sometimes within ±1°C. This level of control is non-negotiable when joining materials with different thermal expansion rates or when working with heat-sensitive alloys.

Understanding the Trade-offs

Choosing the wrong temperature, even by a small margin, can lead to process failure.

The Risk of Excessive Heat

If the temperature is too high, you risk damaging the parent materials. This can cause unwanted grain growth, distortion of the parts, or even partial melting, all of which compromise the assembly's structural integrity.

The Risk of Insufficient Heat

If the temperature is too low, the filler metal will not become fully liquid. This results in poor flow, creating voids and gaps within the joint. An incomplete bond is a weak bond and will almost certainly fail under stress.

Cost and Process Efficiency

Higher-temperature cycles consume more energy and take longer to run. The process should be engineered to use the optimal temperature for the shortest time necessary to ensure filler flow, maximizing both quality and efficiency.

How to Determine the Right Temperature for Your Project

The correct temperature is dictated entirely by your materials and your desired outcome.

- If your primary focus is joining common steels with a nickel-based filler: You will most likely operate within the standard 950°C to 1150°C range to ensure proper flow of the filler alloy.

- If your primary focus is joining heat-sensitive or dissimilar materials: The precise temperature control and uniformity of the furnace are the most critical factors for success, far more than its maximum temperature rating.

- If your primary focus is ensuring maximum joint strength and purity: The combination of the correct temperature and a deep vacuum level is essential to prevent oxidation and remove trapped gases from the bond.

Ultimately, the right temperature is not a feature of the furnace, but a carefully engineered parameter of your specific brazing process.

Summary Table:

| Parameter | Typical Range / Key Fact |

|---|---|

| Typical Brazing Temperature | 927°C - 1232°C (1700°F - 2250°F) |

| Governing Factor | Melting point of the filler metal, not the furnace's maximum capability |

| Furnace Capability | Often up to 1650°C or higher for other processes (annealing, sintering) |

| Critical Requirement | Exceptional temperature uniformity (±5°C) and precise control (±1°C) |

| Primary Goal | Melt filler metal without damaging parent materials in an oxidation-free vacuum |

Achieve Uncompromising Quality in Your Critical Brazing Operations

Precision temperature control is the foundation of a successful vacuum brazing process. KINTEK's advanced high-temperature furnace solutions, including our robust Vacuum & Atmosphere Furnaces, are engineered to deliver the exceptional thermal uniformity and stability your most demanding applications require.

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories and production facilities with advanced thermal processing solutions. Our strong deep customization capability allows us to tailor a furnace system to precisely meet your unique brazing cycle requirements, ensuring flawless, high-strength joints every time.

Ready to perfect your brazing process? Contact our experts today to discuss how a KINTEK vacuum furnace can enhance your results.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does a vacuum brazing furnace enhance 17-4PH aging? Precision Microstructure & Superior Surface Integrity

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is precise temperature and time control in a vacuum brazing furnace necessary for joint performance? Get Expert Tips

- How do the radiant heating and controlled cooling functions of a vacuum brazing furnace benefit Kovar-to-SS joints?