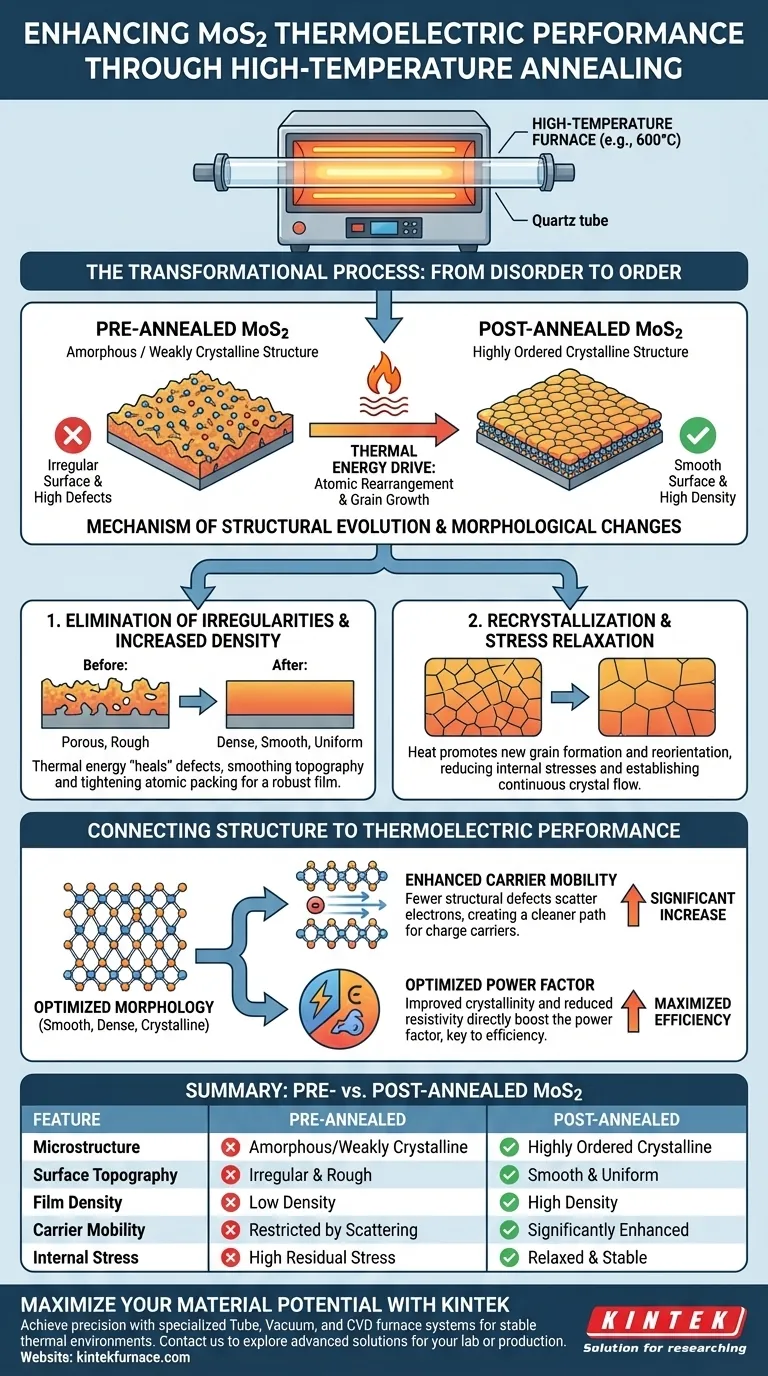

The annealing process modifies MoS2 morphology by leveraging high thermal energy to drive atomic rearrangement and grain growth. This transformation eliminates irregular surface microstructures, resulting in a significantly smoother and denser thin film.

Core Takeaway Thermal processing converts Molybdenum Disulfide films from an amorphous or weakly crystalline state into a highly ordered structure. This morphological refinement reduces electron scattering, directly enhancing carrier mobility and the power factor, which are the defining metrics of thermoelectric efficiency.

The Mechanism of Structural Evolution

Thermal Energy and Atomic Rearrangement

In a high-temperature furnace, typically around 600°C, the thermal energy provided acts as a catalyst for structural change.

This energy forces the atoms within the MoS2 film to break free from their initial, often disordered positions.

Once mobilized, these atoms rearrange themselves into a more energetically stable, ordered lattice structure.

Recrystallization and Grain Growth

The process shifts the material from an amorphous or weakly crystalline state toward a robust crystalline phase.

Heat encourages the formation of new grains and allows existing grains to reorient.

This growth and reorientation are critical for reducing internal stresses and establishing a continuous crystal flow throughout the film.

Specific Morphological Changes

Elimination of Surface Irregularities

Before annealing, MoS2 films often exhibit irregular microstructures that can impede performance.

The annealing process effectively "heals" these defects, smoothing out the film's topography.

Increased Film Density

As grains grow and atoms settle into an ordered lattice, the overall packing of the material tightens.

This results in a denser thin film, which is structurally more robust than the pre-annealed precursor.

connecting Structure to Performance

Enhancing Carrier Mobility

The elimination of physical irregularities and the increase in surface smoothness create a "cleaner" path for charge carriers.

With fewer structural defects to scatter electrons, carrier mobility increases significantly.

Optimizing the Power Factor

The power factor is a composite metric essential for thermoelectric performance.

By optimizing the microscopic morphology—specifically through improved crystallinity and reduced resistivity—the annealing process directly boosts this power factor.

Understanding the Necessity of Control

The Importance of a Controlled Environment

While heat is the driver, the environment must be strictly regulated, often using a Quartz Tube Furnace.

Precise temperature control is required to facilitate recrystallization without degrading the material.

Managing Internal Stress

Proper annealing does not just grow grains; it relaxes the material.

The rearrangement of grains reduces the metal's internal stresses, preventing mechanical failures or cracks that could interrupt electrical continuity.

Making the Right Choice for Your Goal

To maximize the utility of annealing for your specific MoS2 application, consider the following:

- If your primary focus is Electrical Conductivity: Prioritize temperatures that maximize grain size and continuity to minimize resistivity.

- If your primary focus is Structural Integrity: Ensure the annealing schedule allows sufficient time for internal stress relaxation to prevent film cracking.

By strictly controlling the thermal evolution of the microstructure, you transform MoS2 from a disordered material into a high-performance thermoelectric component.

Summary Table:

| Feature | Pre-Annealed MoS2 | Post-Annealed MoS2 |

|---|---|---|

| Microstructure | Amorphous / Weakly Crystalline | Highly Ordered Crystalline |

| Surface Topography | Irregular & Rough | Smooth & Uniform |

| Film Density | Low Density | High Density |

| Carrier Mobility | Restricted by Scattering | Significantly Enhanced |

| Internal Stress | High Residual Stress | Relaxed & Stable |

Maximize Your Material Potential with KINTEK

Ready to achieve precision in your MoS2 thin film processing? Contact us today to explore our advanced solutions.

Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Vacuum, and CVD furnace systems designed to provide the stable thermal environments and precise temperature control necessary for optimal grain growth and stress relaxation. Whether you are conducting research or scaling production, our customizable high-temperature furnaces empower labs and industrial manufacturers to transform disordered materials into high-performance thermoelectric components. Let our expertise drive your success.

Visual Guide

References

- Irasani Rahayu, Melania Suweni Muntini. Effect of Annealing Techniques on the Thermoelectric Properties of Molybdenum Disulfide Thin Films Prepared by RF Sputtering. DOI: 10.1088/1742-6596/3139/1/012035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the different charge operation methods for multi-chamber furnaces? Optimize Your Heat Treatment Process

- What is the primary function of a vacuum annealing furnace? Optimize Zircaloy-4 Alloy Pretreatment and Purity

- Why is the high vacuum environment critical for TB8 titanium matrix composites? Ensuring High-Strength Bonding

- What are the key applications of laboratory vacuum furnaces? Unlock High-Purity Material Processing

- What processes are performed in a high-temperature vacuum furnace? Achieve Purity and Precision in Material Processing

- Why use a high-temp annealing furnace for Fe–32Ni alloy heat treatment? Achieve Microstructural Consistency

- What are the benefits of vacuum brazing for power generation equipment? Achieve Clean, Strong, and Reliable Joints

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density