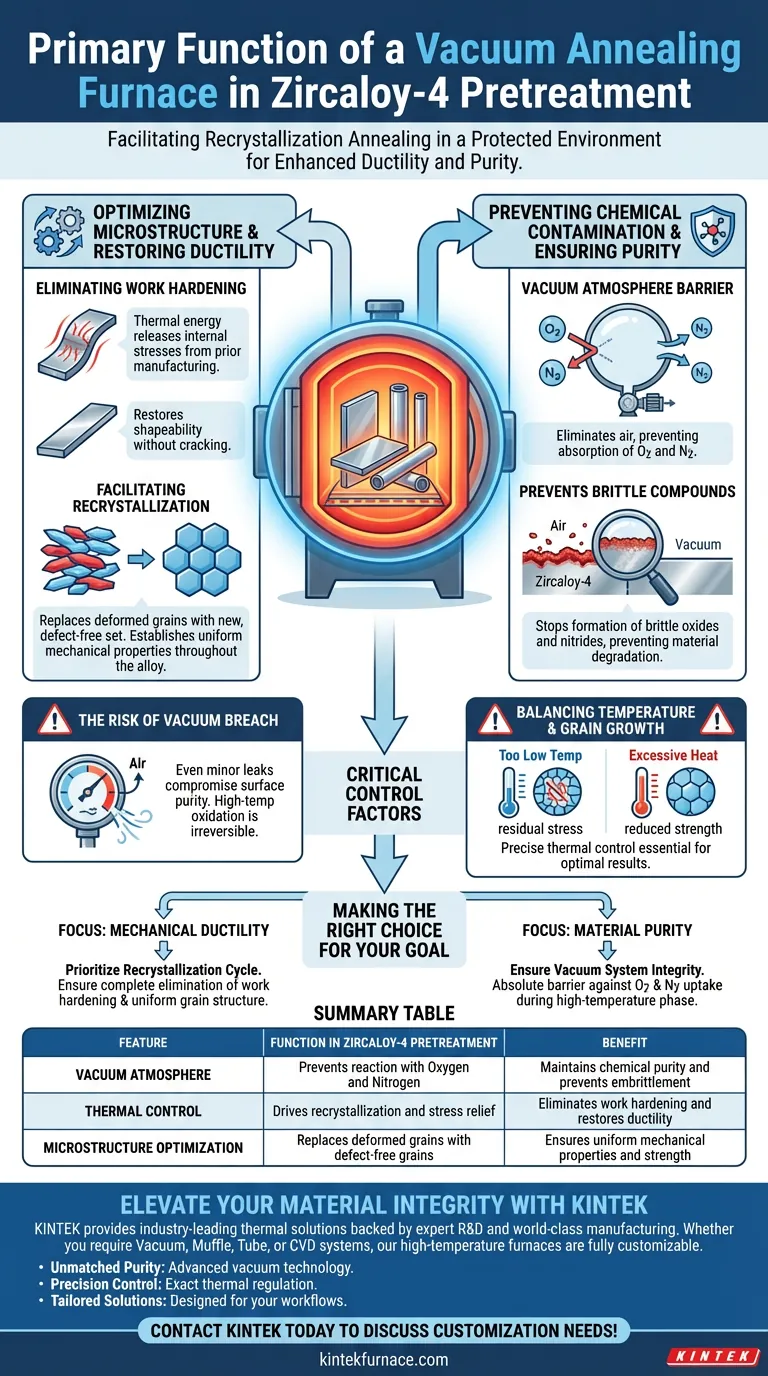

The primary function of a vacuum annealing furnace in the pretreatment of Zircaloy-4 is to facilitate recrystallization annealing within a protected environment. This process eliminates prior work hardening and optimizes the alloy's grain structure to restore ductility. Crucially, the vacuum atmosphere prevents the zirconium from reacting with oxygen and nitrogen at high temperatures, ensuring the material retains its chemical purity and mechanical integrity.

The vacuum annealing furnace serves a critical dual purpose: it acts as a mechanism for microstructural recovery to reverse work hardening, while simultaneously functioning as a protective barrier against atmospheric contamination.

Optimizing Microstructure and Purity

To understand the necessity of this equipment, one must look beyond simple heating. The furnace addresses the specific chemical and physical sensitivities of Zircaloy-4 through precise environmental control.

Eliminating Work Hardening

Prior manufacturing steps often leave Zircaloy-4 plates in a state of high stress, known as work hardening.

The furnace provides the thermal energy required to release these internal stresses. This restores the material's ability to be shaped and worked without cracking.

Facilitating Recrystallization

Beyond simple stress relief, the furnace drives recrystallization.

This process replaces deformed grains with a new set of defect-free grains. This optimization of the grain structure is essential for establishing uniform mechanical properties throughout the alloy.

Preventing Chemical Contamination

Zirconium alloys are highly reactive at elevated temperatures.

If exposed to air during annealing, Zircaloy-4 would absorb oxygen and nitrogen. The vacuum environment eliminates these gases, preventing the formation of brittle oxides and nitrides that would degrade the base material.

Understanding the Critical Control Factors

While the vacuum annealing furnace is a powerful tool, its effectiveness relies on strict adherence to process parameters. Failing to control these variables can lead to suboptimal results.

The Risk of Vacuum Breach

The integrity of the vacuum is paramount. Even minor leaks can introduce enough oxygen to compromise the surface purity of the Zircaloy-4.

High-temperature oxidation is irreversible and can render the material unsuitable for nuclear or critical structural applications.

Balancing Temperature and Grain Growth

Thermal control must be precise.

If the temperature is too low, recrystallization will be incomplete, leaving residual stresses. Conversely, excessive heat or prolonged exposure can lead to grain coarsening, where grains grow too large, reducing the material's strength.

Making the Right Choice for Your Goal

When configuring your pretreatment process for Zircaloy-4, your operational focus will dictate your specific furnace parameters.

- If your primary focus is mechanical ductility: Prioritize the recrystallization cycle to ensure complete elimination of work hardening and a uniform grain structure.

- If your primary focus is material purity: Ensure the vacuum system acts as an absolute barrier to prevent oxygen and nitrogen uptake during the high-temperature phase.

The vacuum annealing furnace is not merely a heater; it is a precision instrument for defining the final quality and reliability of Zircaloy-4 components.

Summary Table:

| Feature | Function in Zircaloy-4 Pretreatment | Benefit |

|---|---|---|

| Vacuum Atmosphere | Prevents reaction with Oxygen and Nitrogen | Maintains chemical purity and prevents embrittlement |

| Thermal Control | Drives recrystallization and stress relief | Eliminates work hardening and restores ductility |

| Microstructure Optimization | Replaces deformed grains with defect-free grains | Ensures uniform mechanical properties and strength |

Elevate Your Material Integrity with KINTEK

Precision is non-negotiable when treating sensitive alloys like Zircaloy-4. KINTEK provides industry-leading thermal solutions backed by expert R&D and world-class manufacturing. Whether you require Vacuum, Muffle, Tube, or CVD systems, our high-temperature furnaces are fully customizable to meet your specific lab or industrial requirements.

Our value to you:

- Unmatched Purity: Advanced vacuum technology to eliminate atmospheric contamination.

- Precision Control: Exact thermal regulation to manage grain growth and ductility.

- Tailored Solutions: Systems designed specifically for your unique metallurgical workflows.

Ready to optimize your annealing process? Contact KINTEK today to discuss your customization needs with our technical specialists!

Visual Guide

References

- Huifang Yue, Meiyi Yao. Effects of Hydrogenation on the Corrosion Behavior of Zircaloy-4. DOI: 10.3390/ma17051101

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Can High Vacuum Melting Furnaces be customized? Tailor Precision Solutions for Your Lab

- Why is a laboratory vacuum environment critical for A357 aluminum alloy sintering? Achieve High-Density Performance

- Why is a vacuum oven essential for photocatalyst preparation? Ensure Nanostructural Integrity and Purity

- How does the low-pressure environment of an RH vacuum refining furnace influence the morphology of a supersonic jet?

- How does the energy consumption of a vacuum furnace compare to a salt bath furnace? Discover the Efficiency Edge

- How does vacuum carburizing ensure stable carburizing quality? Achieve Precise, Repeatable Heat Treatment

- What quenching processes can be achieved with a vacuum heat treatment furnace? Unlock Precision and Purity for Superior Results

- What is the function of a Spark Plasma Sintering (SPS) system in the preparation of porous tungsten gradient precursors?