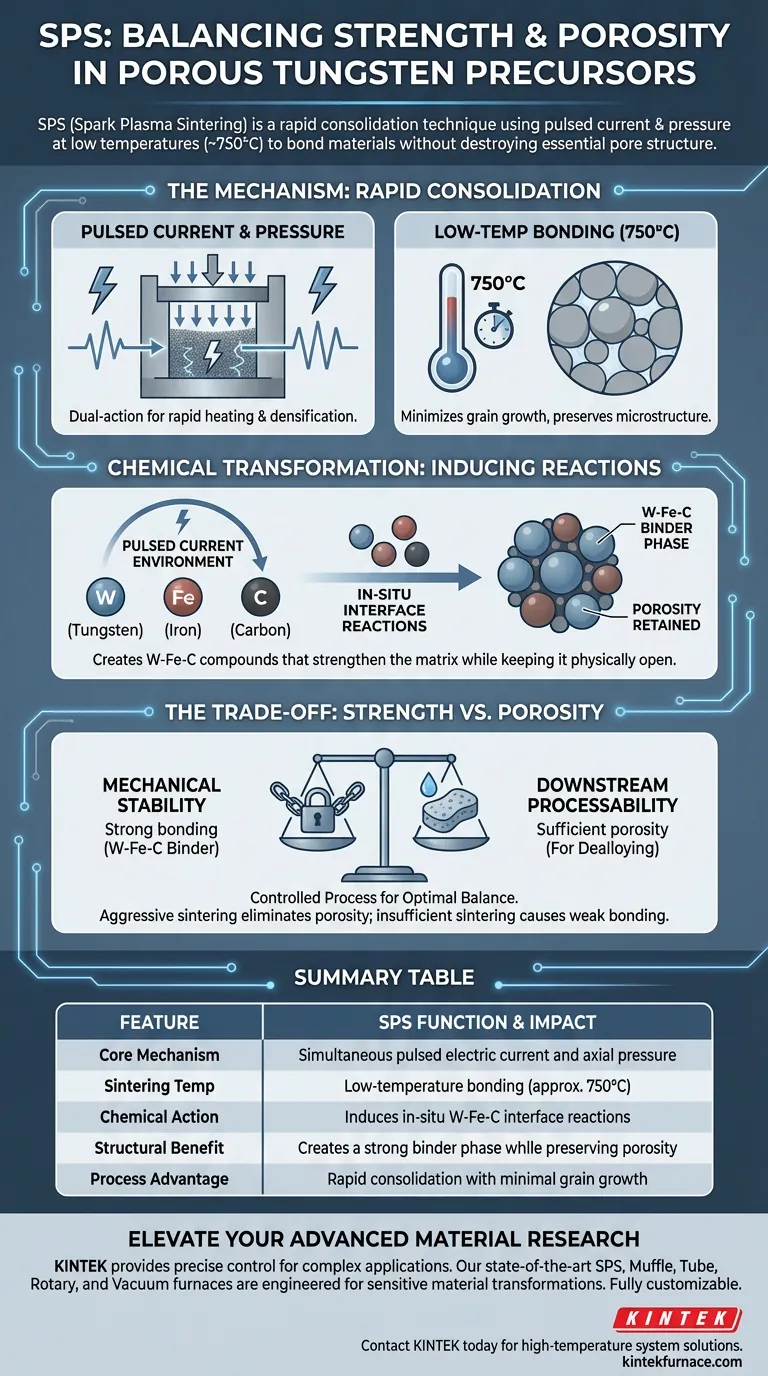

Spark Plasma Sintering (SPS) functions as a specialized rapid consolidation technique that utilizes pulsed electric current and axial pressure to bond porous tungsten gradient precursors. By operating at a relatively low temperature of 750°C for a short duration, the system secures the structural integrity of the material without eliminating the essential pore structure required for subsequent processing.

By inducing specific in-situ interface reactions, SPS creates a distinct W-Fe-C binder phase that strengthens the matrix. This process strikes a critical balance: it provides enough bonding strength to hold the precursor together while retaining sufficient porosity for future dealloying treatments.

The Mechanism of Rapid Consolidation

Utilizing Pulsed Current and Pressure

The SPS system distinguishes itself from conventional sintering by applying pulsed electric current simultaneously with axial pressure.

This dual-action approach allows for rapid heating and material densification. The energy is delivered directly to the particles, facilitating fast consolidation.

Achieving Low-Temperature Bonding

A defining feature of this process is its ability to operate effectively at 750 degrees Celsius.

This is considered a relatively low temperature for tungsten-based materials. By minimizing thermal exposure, the system prevents excessive grain growth and preserves the material's microstructural intent.

Chemical Transformation and Bonding

Inducing In-Situ Interface Reactions

Beyond simple physical compression, the SPS process triggers chemical changes at the particle boundaries.

It induces in-situ interface reactions between the constituent elements: tungsten (W), iron (Fe), and carbon (C). These reactions occur rapidly due to the pulsed current environment.

The Role of W-Fe-C Compounds

The product of these reactions is the formation of W-Fe-C compounds.

These compounds act as a critical binder phase within the matrix. This binder significantly enhances the bonding strength between the matrix particles, ensuring the precursor is mechanically stable.

Understanding the Trade-offs

The Tension Between Strength and Porosity

The primary challenge in preparing these precursors is balancing mechanical durability with permeability.

If the sintering process is too aggressive—either through higher temperatures or longer durations—the material becomes too dense. This eliminates the porosity needed for subsequent dealloying treatments, rendering the precursor useless for its intended application.

Managing Reaction Extent

Conversely, insufficient sintering results in weak bonding.

If the W-Fe-C binder phase does not form adequately, the matrix particles will not adhere to one another. The SPS system navigates this trade-off by strictly controlling the time and temperature windows to ensure just enough reaction occurs to bind the particles without sealing the voids.

Making the Right Choice for Your Goal

To optimize the preparation of porous tungsten gradient precursors, you must prioritize your processing parameters based on the desired material state.

- If your primary focus is mechanical stability: Prioritize the formation of the W-Fe-C binder phase to ensure the matrix particles are securely bonded.

- If your primary focus is downstream processability: Ensure the sintering duration remains short and temperatures do not exceed 750°C to retain sufficient porosity for dealloying.

Success relies on leveraging the SPS system to harden the structure chemically while keeping it physically open.

Summary Table:

| Feature | SPS Function & Impact |

|---|---|

| Core Mechanism | Simultaneous pulsed electric current and axial pressure |

| Sintering Temp | Low-temperature bonding (approx. 750°C) |

| Chemical Action | Induces in-situ W-Fe-C interface reactions |

| Structural Benefit | Creates a strong binder phase while preserving porosity |

| Process Advantage | Rapid consolidation with minimal grain growth |

Elevate Your Advanced Material Research with KINTEK

Precise control over sintering parameters is vital for complex applications like porous tungsten gradient precursors. KINTEK provides state-of-the-art laboratory solutions, including SPS, Muffle, Tube, Rotary, and Vacuum furnaces, specifically engineered to handle sensitive material transformations.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique research needs, ensuring the perfect balance between mechanical strength and material porosity.

Ready to optimize your sintering process? Contact KINTEK today to discover how our high-temperature systems can empower your next breakthrough.

Visual Guide

References

- Ke Zhu, Jian Zhang. The Integrated Preparation of Porous Tungsten Gradient Materials with a Wide Porosity Range. DOI: 10.3390/met14040427

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How do continuous vacuum furnaces improve energy efficiency in metal heat treatment? Achieve Superior Heat Treatment Efficiency

- What role does a high vacuum oven play in rock sample pre-treatment? Ensure High-Precision Microstructural Monitoring

- How should one choose between a vacuum furnace and an atmosphere furnace? Select the Right Furnace for Your Process

- What heating methods are available for vacuum graphitizing furnaces? Induction vs. Resistance Heating Explained

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the purpose of the hot zone in a vacuum furnace and what materials are commonly used for heat shielding? Optimize Your High-Temp Processes

- What is the significance of the thermal hysteresis temperature difference (Xth) in vacuum sintering? Control Heat Lag