At its core, a continuous vacuum furnace achieves superior energy efficiency by eliminating the single largest source of waste in traditional heat treatment: the constant reheating of the furnace itself. Unlike batch furnaces that must cool down and ramp back up, a continuous system maintains a stable operating temperature, directing thermal energy almost exclusively into the product, not the equipment. This fundamental shift is amplified by a vacuum environment that prevents heat loss and advanced designs that contain and recycle energy.

The primary efficiency gain isn't just from a single feature, but from a holistic system designed to minimize thermal waste. By running continuously, containing heat with advanced materials, and using a vacuum to optimize energy transfer, these furnaces fundamentally change the energy equation of heat treatment.

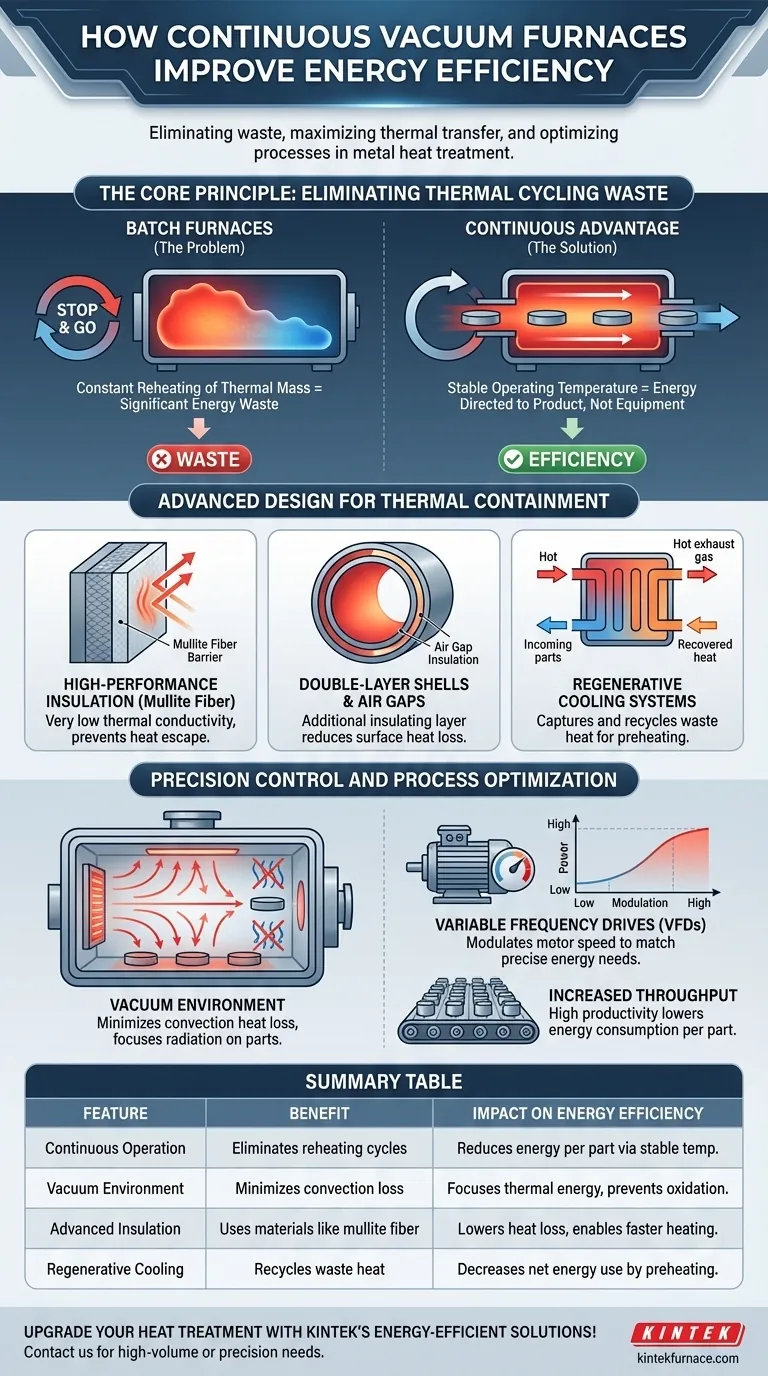

The Core Principle: Eliminating Thermal Cycling Waste

The most significant energy savings in a continuous vacuum furnace come from its operational design, which directly counters the inherent inefficiency of batch processing.

The Problem with Batch Furnaces

Traditional batch furnaces operate in start-stop cycles. A load is placed inside, the entire furnace is heated to a target temperature, held, and then cooled before the next cycle can begin.

The vast majority of energy in this process is spent heating the furnace's massive thermal mass—its walls, fixtures, and atmosphere—from ambient temperature. This energy is then largely lost to the environment during the cooling phase.

The Continuous Advantage

A continuous furnace maintains a stable thermal profile. Parts move through distinct heating and cooling zones without the furnace itself ever cooling down.

This eliminates the "reheating penalty." Energy input is only required to compensate for minor thermal losses and, most importantly, to heat the product moving through the system. This results in a dramatically lower energy consumption per part processed.

Advanced Design for Thermal Containment

Modern continuous vacuum furnaces pair their operational efficiency with physical designs engineered to keep heat precisely where it is needed.

High-Performance Insulation

These furnaces utilize materials like high-quality polycrystalline mullite fiber. This advanced insulation has very low thermal conductivity, acting as a highly effective barrier that prevents heat from escaping the furnace chamber.

This allows the furnace to reach and maintain its target temperature quickly while consuming significantly less energy compared to older, less effective insulation materials.

Double-Layer Shells & Air Gaps

Many designs incorporate double-layer furnace shells with an air gap in between. This feature uses air as an additional insulating layer, further reducing heat loss from the furnace's exterior surface. It is a simple but highly effective method for thermal containment.

Regenerative Cooling Systems

Instead of simply venting waste heat, advanced furnaces can use regenerative cooling systems. These systems capture heat from exhaust gases or from the cooling zones of the furnace and recycle it, using it to preheat incoming parts or for other processes, further reducing net energy consumption.

Precision Control and Process Optimization

The efficiency of a continuous vacuum furnace is also a product of how precisely it manages the heat treatment environment.

The Role of the Vacuum

Operating under a vacuum is itself an energy-saving measure. By removing most of the air, the furnace eliminates heat transfer through convection, a primary source of heat loss in conventional furnaces.

This means that thermal energy, primarily transferred via radiation, is focused directly onto the parts. A secondary benefit is the prevention of oxidation, which improves surface quality and eliminates the need for energy-intensive secondary cleaning processes.

Variable Frequency Drives (VFDs)

Modern furnaces employ VFDs on motors for pumps and cooling fans. Instead of running at 100% power at all times, VFDs modulate the motor's speed and energy consumption to match the precise demands of the current process stage. This granular control prevents significant energy waste during less-demanding phases of the cycle.

Increased Throughput as an Efficiency Metric

The uninterrupted operation of a continuous furnace maximizes throughput and minimizes downtime. When evaluated on an energy-per-part basis, this high productivity is a critical component of overall efficiency. Processing more material with the same or less energy is a definitive measure of an efficient system.

Understanding the Trade-offs and Considerations

While highly efficient, continuous vacuum furnaces are not the universal solution for all heat treatment needs. Understanding their limitations is crucial for making an informed decision.

High Initial Capital Cost

The primary drawback is the significant initial investment. The complex automation, advanced materials, and larger footprint make these systems substantially more expensive to purchase and install than conventional batch furnaces.

Reduced Processing Flexibility

These furnaces are optimized for high-volume, low-mix production. They excel when processing a steady stream of similar parts. They are inefficient and impractical for job shops or R&D environments that require frequent changes in temperature profiles, cycle times, or part geometries.

Maintenance and Operational Complexity

The automated systems that enable continuous operation are inherently more complex. Maintenance requires specialized knowledge, and troubleshooting can be more involved compared to simpler batch units. A production halt due to a fault can have a larger impact than a single stalled batch furnace.

Making the Right Choice for Your Operation

Ultimately, the decision to invest in a continuous vacuum furnace depends entirely on your specific production goals and operational scale.

- If your primary focus is high-volume manufacturing of a consistent product: The unparalleled energy and operational efficiency of a continuous furnace provides a clear and compelling return on investment.

- If your primary focus is ultimate material quality and precision: The controlled vacuum environment is essential for sensitive applications in aerospace, medical, or electronics, making it the superior choice regardless of volume.

- If your primary focus is flexibility for varied, small-batch work: The high capital cost and lack of agility make a continuous furnace unsuitable; modern, efficient batch furnaces remain the more practical and economical solution.

Choosing the right furnace technology is about aligning the tool's inherent strengths with your specific manufacturing strategy.

Summary Table:

| Feature | Benefit | Impact on Energy Efficiency |

|---|---|---|

| Continuous Operation | Eliminates reheating cycles | Reduces energy consumption per part by maintaining stable temperature |

| Vacuum Environment | Minimizes heat loss via convection | Focuses thermal energy on parts, preventing oxidation and secondary cleaning |

| Advanced Insulation | Uses materials like mullite fiber | Lowers heat loss, enabling faster heating with less energy |

| Regenerative Cooling | Recycles waste heat | Decreases net energy use by preheating parts or other processes |

| Variable Frequency Drives | Modulates motor speeds | Prevents energy waste by matching power to process demands |

| High Throughput | Processes more parts with less downtime | Improves energy-per-part efficiency in high-volume production |

Upgrade your metal heat treatment with KINTEK's energy-efficient solutions! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in high-volume manufacturing or precision-focused industries like aerospace and medical, our furnaces deliver superior energy savings and performance. Contact us today to discuss how we can optimize your processes and reduce costs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control