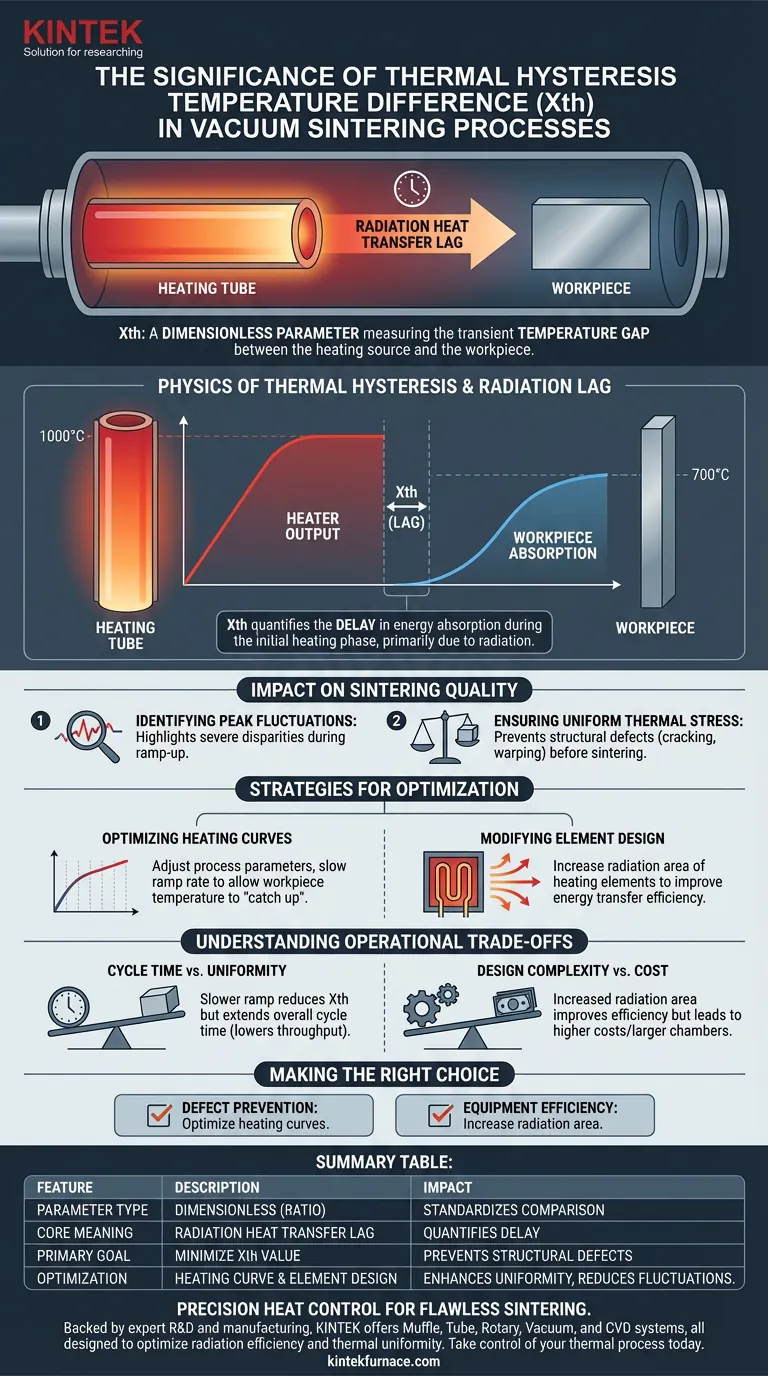

The thermal hysteresis temperature difference (Xth) is a dimensionless parameter that quantitatively measures the transient temperature gap between the heating source (tube) and the workpiece during vacuum sintering. This metric is significant because it defines the radiation heat transfer lag—the delay between the heater reaching a temperature and the workpiece absorbing that energy—which is critical for controlling quality during the initial heating phase.

The calculation of Xth allows operators to identify and control peak temperature fluctuations during the ramp-up phase. By minimizing this value, manufacturers can ensure uniform thermal stress, preventing defects caused by uneven heating.

The Physics of Thermal Hysteresis

Understanding Radiation Lag

In a vacuum environment, heat transfer relies primarily on radiation rather than convection. This mechanism creates an inherent delay, or lag, between the energy output of the heating tube and the energy absorption of the workpiece. Xth provides a specific numerical value to represent this delay.

The Role of the Parameter

Xth is a dimensionless parameter, meaning it describes a ratio or relationship rather than a raw temperature value. This allows for a standardized way to compare heating efficiency and lag across different furnace setups or process cycles.

Impact on Sintering Quality

Identifying Peak Fluctuations

The primary operational significance of Xth is its ability to highlight peak temperature fluctuations. These disparities are most severe during the initial heating phase when the furnace is ramping up from ambient temperatures.

Ensuring Uniform Thermal Stress

If the temperature difference between the heater and the part is too great, the workpiece experiences uneven expansion. By monitoring and reducing Xth, operators ensure uniform thermal stress. This prevents structural integrity issues, such as cracking or warping, before the material even reaches its final sintering temperature.

Strategies for Optimization

Optimizing Heating Curves

One of the most effective ways to reduce the thermal hysteresis effect is by adjusting the process parameters. Optimizing heating curves—specifically by slowing the ramp rate—allows the workpiece temperature to "catch up" to the heating tube, minimizing the Xth value.

Modifying Element Design

Optimization can also be achieved through hardware changes. Increasing the radiation area of the heating elements improves the efficiency of energy transfer. This physical change reduces the lag time, thereby lowering the Xth value naturally.

Understanding the Operational Trade-offs

Cycle Time vs. Uniformity

While minimizing Xth is ideal for quality, achieving a near-zero hysteresis often requires significantly slowing down the heating ramp. This extends the overall cycle time and can reduce production throughput.

Design Complexity vs. Cost

Increasing the radiation area of heating elements effectively reduces hysteresis but impacts furnace design. This approach may lead to higher equipment costs or require larger furnace chambers to accommodate the increased surface area of the heating elements.

Making the Right Choice for Your Goal

To effectively manage thermal hysteresis in your vacuum sintering process, consider your specific priorities:

- If your primary focus is defect prevention: Optimize your heating curves to minimize Xth, ensuring the workpiece experiences uniform stress during the critical initial heating phase.

- If your primary focus is equipment efficiency: Increase the radiation area of your heating elements to physically reduce the heat transfer lag without necessarily extending cycle times.

By quantifying the lag between your heater and your workpiece, you transform a hidden variable into a controllable process parameter.

Summary Table:

| Feature | Description | Impact on Sintering |

|---|---|---|

| Parameter Type | Dimensionless (Ratio) | Standardizes heating efficiency comparison |

| Core Meaning | Radiation heat transfer lag | Quantifies delay between heater and workpiece |

| Primary Goal | Minimize Xth value | Prevents structural defects like warping/cracking |

| Optimization | Heating curve & element design | Enhances uniformity and reduces peak fluctuations |

Precision Heat Control for Flawless Sintering

Thermal hysteresis can be the difference between a high-performance part and a costly failure. At KINTEK, we understand that controlling the Xth parameter requires more than just standard equipment—it requires precision engineering.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to optimize radiation efficiency and thermal uniformity. Whether you need to refine your heating curves or require a customizable lab high-temp furnace tailored to your unique sintering needs, our team is ready to assist.

Take control of your thermal process today. Contact our experts now to discuss your custom furnace solution.

Visual Guide

References

- Mao Li, Hesong Li. Numerical simulation of the heating process in a vacuum sintering electric furnace and structural optimization. DOI: 10.1038/s41598-024-81843-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why are specific temperature gradients utilized in a vacuum drying oven? Master Mixed Matrix Membrane Preparation

- What materials can be used for retorts in hot wall furnaces? Choose the Right Material for Your Process

- Why must the drying process for MXene-coated electrodes be conducted in a vacuum drying oven? Key Stability Factors

- What core process conditions does an industrial vacuum brazing furnace provide for joining X37CrMoV5-1 tool steel?

- What is vacuum brazing and what materials does it primarily join? Discover High-Purity Joining for Superior Bonds

- 1200°C Annealing for LPBF Silicon Steel (Fe-Si): Enhancing Soft Magnetic Performance

- How does a vacuum furnace facilitate precise control of tellurium vacancy concentrations in PtTe2 thin films?

- What is the function of a vacuum drying oven in processing mixed TiB2-SiC slurries? Protect Material Integrity