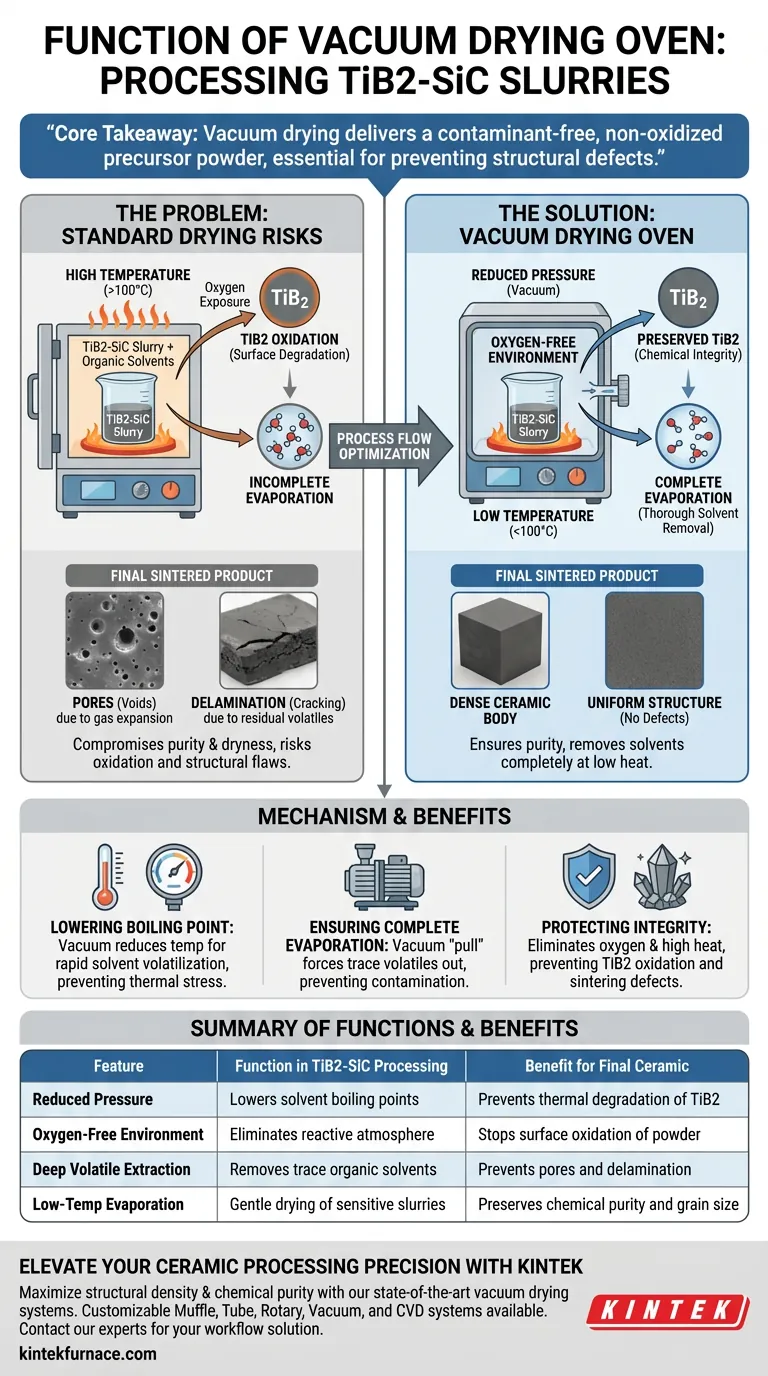

A vacuum drying oven is primarily used to remove organic solvents from mixed TiB2-SiC slurries at reduced temperatures to preserve the chemical integrity of the powder. By operating under negative pressure, the oven lowers the boiling point of the solvents, enabling efficient evaporation without exposing the sensitive Titanium Diboride (TiB2) to oxidation-inducing heat levels.

Core Takeaway Vacuum drying solves the conflict between needing to remove solvents completely and needing to avoid high temperatures. Its main function is to deliver a contaminant-free, non-oxidized precursor powder, which is the absolute prerequisite for preventing structural defects like pores and delamination during the final sintering process.

The Mechanism of Solvent Removal

Lowering the Boiling Point

The fundamental advantage of this equipment is the manipulation of atmospheric pressure. By creating a vacuum, the oven significantly reduces the temperature required for organic solvents to boil and volatilize.

This allows the slurry to dry rapidly at temperatures well below the standard boiling point of the solvent. It creates a gentle drying environment that protects the material components from thermal stress.

Ensuring Complete Evaporation

Simple air drying often leaves trace amounts of solvent trapped deep within the powder mixture. A vacuum drying oven exerts a "pull" that forces these volatiles out of the slurry.

This thorough removal is critical because any residual organic solvent left in the mixture will become a contaminant in later processing stages.

Protecting Chemical and Structural Integrity

Preventing TiB2 Oxidation

Titanium Diboride (TiB2) is prone to oxidation and degradation when exposed to high temperatures in the presence of oxygen. Standard drying methods often require heat levels that trigger these chemical changes.

The vacuum drying oven mitigates this risk entirely. By removing the oxygen environment and lowering the required heat, it ensures the TiB2 powder retains its purity and intended chemical composition.

Preventing Sintering Defects

The quality of the drying phase dictates the success of the subsequent sintering stage. If solvents remain in the powder, they will vaporize violently when the material is eventually fired at high temperatures.

This gas expansion causes pores (voids) inside the dense ceramic body. In layered or compacted structures, it causes delamination (cracking/separation). Vacuum drying eliminates the root cause of these defects.

Understanding the Trade-offs

The Risk of Standard Drying

Attempting to bypass vacuum drying often leads to a compromise between purity and dryness. If you use a standard oven at low temperatures, you risk incomplete solvent removal.

If you raise the temperature in a standard oven to force the solvent out, you accelerate surface oxidation of the TiB2. This oxidation creates a surface layer that inhibits grain growth and densification, ultimately weakening the final composite material.

Making the Right Choice for Your Goal

To maximize the effectiveness of your TiB2-SiC processing, align your drying parameters with your specific material requirements.

- If your primary focus is Chemical Purity: Prioritize high-vacuum levels to allow for the lowest possible temperature settings, minimizing any chance of TiB2 surface oxidation.

- If your primary focus is Structural Density: Ensure the drying cycle is sufficiently long to guarantee absolute solvent removal, as even trace volatiles will create porosity during sintering.

Precision in the drying phase is the invisible foundation of high-performance ceramics.

Summary Table:

| Feature | Function in TiB2-SiC Processing | Benefit for Final Ceramic |

|---|---|---|

| Reduced Pressure | Lowers solvent boiling points | Prevents thermal degradation of TiB2 |

| Oxygen-Free Environment | Eliminates reactive atmosphere | Stops surface oxidation of powder |

| Deep Volatile Extraction | Removes trace organic solvents | Prevents pores and delamination |

| Low-Temp Evaporation | Gentle drying of sensitive slurries | Preserves chemical purity and grain size |

Elevate Your Ceramic Processing Precision

Maximize the structural density and chemical purity of your advanced materials with KINTEK. Our state-of-the-art vacuum drying and high-temperature systems are engineered to prevent oxidation and eliminate porosity in sensitive precursors like TiB2-SiC.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique lab requirements. Don't let residual solvents compromise your sintering results—contact our experts today to find the perfect drying solution for your workflow!

Visual Guide

References

- German Alberto Barragán De Los Rios, Patricia Fernández‐Morales. Numerical Simulation of Aluminum Foams by Space Holder Infiltration. DOI: 10.1007/s40962-024-01287-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a vacuum drying oven play in graphene cathode manufacturing? Achieve High-Performance Battery Components

- What is the purpose of using a vacuum drying oven for carbon microspheres? Optimize Your Material Activation

- How does the high-power rapid scanning preheating cycle affect material quality? Stabilize PBF-EB & Prevent Cracking

- Why is a two-step cooling system necessary for titanium hydrogenation? Protect Your Alloy’s Integrity

- Why is a vacuum environment important in a vacuum furnace? Ensure Purity and Precision in Material Processing

- What safety benefits do vacuum furnaces offer? Inherently Safer High-Temperature Processing

- What is the significance of vacuum degree in vacuum sintering furnaces? Optimize Material Purity and Performance

- Why use vacuum and argon in pulse solidification? Protect your Aluminum-Silicon alloys from oxidation and contamination