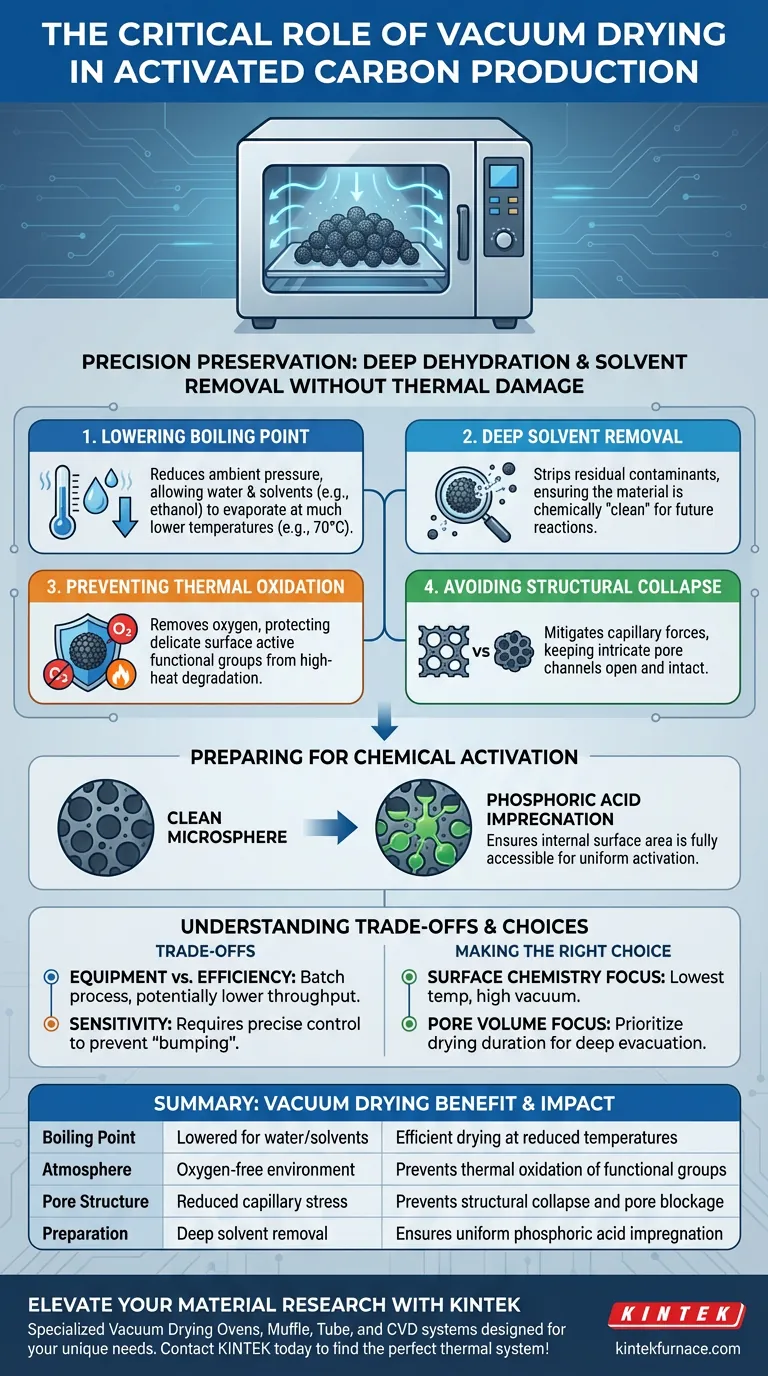

Vacuum drying is the critical preservation step that allows for deep dehydration and solvent removal without compromising the chemical structure of the material. By lowering the boiling point of liquids like water and ethanol, this method dries carbon microspheres at significantly reduced temperatures, preventing thermal damage to the surface and ensuring the pores are physically accessible for activation.

The core purpose of the vacuum drying oven is to decouple drying efficiency from high heat. It preserves sensitive active functional groups by preventing oxidation and clears pore channels of residual solvents, creating an ideal substrate for subsequent chemical impregnation.

The Mechanics of Vacuum Drying

Lowering the Boiling Point

The fundamental advantage of this equipment is its ability to reduce the ambient pressure surrounding the sample. By creating a vacuum, the boiling points of moisture and organic solvents (such as ethanol) are significantly lowered.

This allows liquids trapped deep within the microspheres to evaporate efficiently at much lower temperatures (e.g., 70°C) than would be required at atmospheric pressure.

Deep Solvent Removal

During the conversion process, carbon microspheres often retain residual solvents from washing or synthesis steps. The vacuum oven effectively strips these contaminants from the material.

Removing these residues is essential to prevent interference during later chemical reactions, ensuring the material is chemically "clean" before it undergoes activation.

Protecting Material Integrity

Preventing Thermal Oxidation

One of the greatest risks during drying is the degradation of the carbon surface. High temperatures in the presence of air can lead to the thermal oxidation of active functional groups.

By drying under vacuum, you remove the oxygen source and reduce the thermal load. This preserves the surface chemistry that is vital for the activated carbon's final performance in adsorption applications.

Avoiding Structural Collapse

Standard high-temperature drying can cause capillary forces that lead to the shrinkage or blockage of active pores.

Vacuum drying mitigates this stress, preventing the collapse of the carbon skeleton. This ensures that the intricate pore structure remains open and intact for future processing.

Preparing for Chemical Activation

Clearing Pores for Impregnation

The primary reference highlights that this process prepares "clean pore spaces" specifically for phosphoric acid impregnation.

If pores are clogged with water or solvent, the activating agent cannot penetrate deeply into the microsphere. Vacuum drying ensures the internal surface area is fully accessible, leading to a more uniform and effective activation.

Understanding the Trade-offs

Equipment vs. Efficiency

While vacuum drying yields a superior quality sample, it is generally a batch process that may have lower throughput compared to continuous conveyor drying methods.

Sensitivity to Operational Parameters

The process requires precise control over vacuum levels and temperature ramps. If the pressure drops too suddenly, there is a risk of "bumping" (rapid boiling) that could mechanically disrupt the sample powder, requiring careful monitoring unlike a standard gravity convection oven.

Making the Right Choice for Your Goal

To maximize the utility of the vacuum drying oven, tailor your approach based on the specific attributes you wish to prioritize in your final activated carbon:

- If your primary focus is Surface Chemistry: Maintain the lowest possible temperature under high vacuum to maximize the retention of delicate functional groups on the carbon surface.

- If your primary focus is Pore Volume: Prioritize the duration of the drying cycle to ensure deep capillary water is fully evacuated, maximizing the penetration of the phosphoric acid activating agent.

Ultimately, the vacuum drying oven transforms drying from a potentially destructive heating step into a precision preservation technique.

Summary Table:

| Feature | Vacuum Drying Benefit | Impact on Activated Carbon |

|---|---|---|

| Boiling Point | Lowered for water/solvents | Efficient drying at reduced temperatures |

| Atmosphere | Oxygen-free environment | Prevents thermal oxidation of functional groups |

| Pore Structure | Reduced capillary stress | Prevents structural collapse and pore blockage |

| Preparation | Deep solvent removal | Ensures uniform phosphoric acid impregnation |

Elevate Your Material Research with KINTEK

Precision drying is the foundation of high-performance activated carbon. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum Drying Ovens, Muffle, Tube, and CVD systems designed to preserve delicate surface chemistries and optimize pore accessibility. Whether you are processing carbon microspheres or advanced lab materials, our customizable high-temp solutions are engineered for your unique needs.

Ready to achieve superior dehydration and solvent removal? Contact KINTEK today to find the perfect thermal system for your laboratory!

Visual Guide

References

- Saeed Alhawtali, Chun‐Yang Yin. Date Palm Leaflet-Derived Carbon Microspheres Activated Using Phosphoric Acid for Efficient Lead (II) Adsorption. DOI: 10.3390/c10010026

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- How does a retort furnace compare to a vacuum furnace? Choose the Right Heat Treatment for Your Materials

- Why must Silicon Carbide (SiC) slurry be processed in a vacuum drying oven? Ensure Purity and Prevent Agglomeration

- What is the significance of precise temperature control in a vacuum furnace? Ensure Quality, Consistency, and Reliability

- How does vacuum heating primarily transfer heat to the workpiece? Unlock Uniform Heat for Superior Results

- What are the advantages of using vacuum furnaces? Achieve Superior Metallurgical Control and Purity

- What critical process environments does a vacuum annealing furnace provide? Optimize Sm2Fe17Cx Alloy Heat Treatment

- Why is a vacuum oven necessary in the process flow for producing carbon nanospheres? Secure High Purity & Dispersion

- What technical advantages do electric furnace systems offer for copper slag impoverishment? Maximize Your Metal Recovery