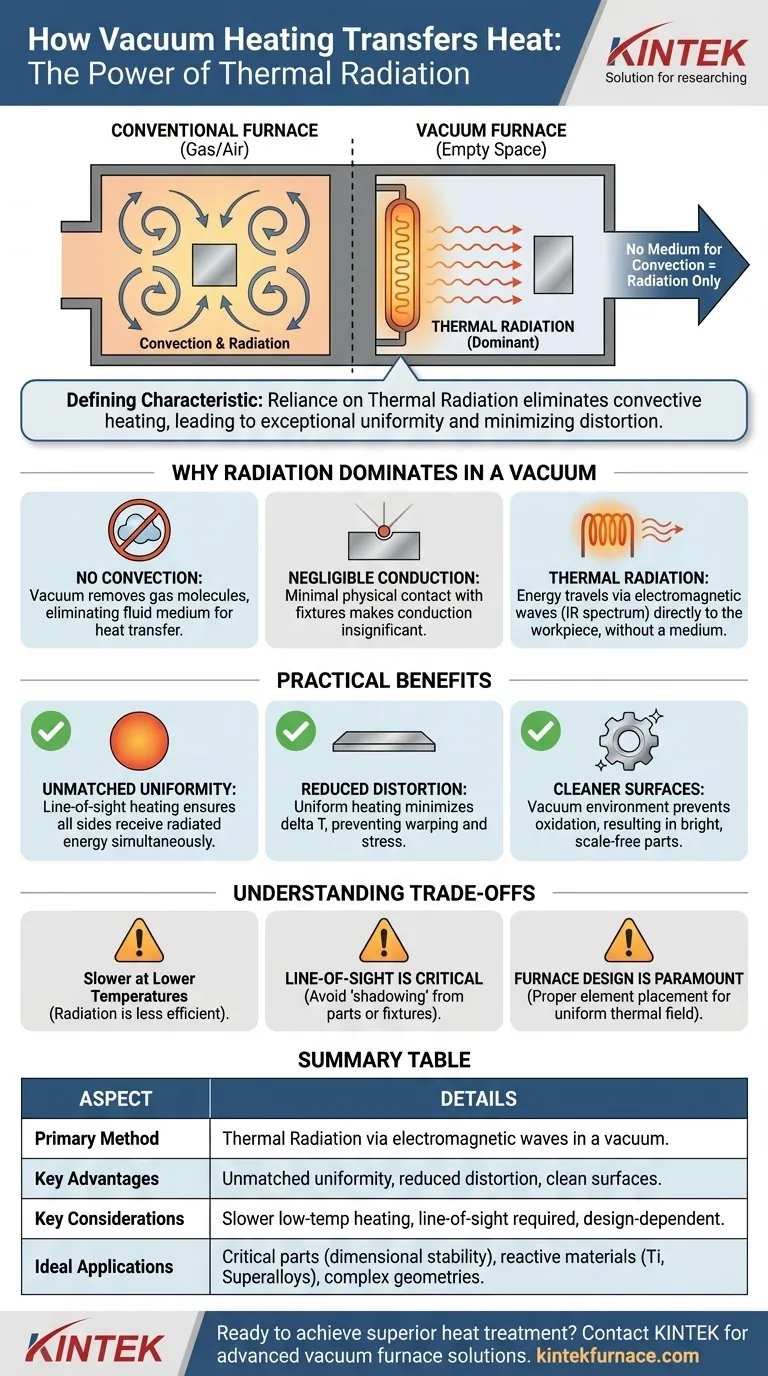

In a vacuum furnace, heat is transferred to the workpiece almost exclusively through the process of thermal radiation. Unlike conventional furnaces that use gas or air to circulate heat, a vacuum environment removes the molecules necessary for convection, leaving radiation as the only effective mechanism for transferring energy across the empty space from the heating elements to the part.

The defining characteristic of vacuum heating is its reliance on thermal radiation. This eliminates convective heating, resulting in slower but exceptionally uniform temperature distribution, which is the key to minimizing part distortion and achieving superior metallurgical properties.

Why Radiation Dominates in a Vacuum

To understand vacuum heating, it's essential to recognize what is absent: a medium. Standard furnaces are filled with air or a controlled atmosphere, which allows for two other forms of heat transfer.

The Absence of Convection

Convection is the transfer of heat through the movement of fluids or gases. Hot gas molecules circulate and come into contact with the workpiece, transferring their energy.

By creating a vacuum, we remove the vast majority of these gas molecules. Without a medium to circulate, heat transfer via convection becomes negligible.

The Minimal Role of Conduction

Conduction is heat transfer through direct physical contact. While the workpiece rests on a fixture, the contact points are incredibly small relative to the total surface area.

Therefore, the amount of heat transferred through conduction is insignificant in the overall heating process.

The Power of Thermal Radiation

Thermal radiation is the transfer of energy via electromagnetic waves, specifically in the infrared spectrum. This process does not require any medium to travel through.

The heating elements in a vacuum furnace glow hot and emit thermal radiation in all directions. These energy waves travel across the vacuum space and are absorbed by the surface of the workpiece, causing its temperature to rise.

The Practical Implications of Radiation Heating

Relying on radiation is not just a technical necessity; it provides distinct advantages that are critical for high-performance applications.

Unmatched Temperature Uniformity

Because the heating elements and hot walls of the furnace surround the workpiece, it receives radiated energy from all directions simultaneously.

This "line-of-sight" heating is inherently more uniform than convection, which can suffer from uneven gas flow and create hot or cold spots.

Reduced Thermal Stress and Deformation

The most significant benefit is a dramatic reduction in part distortion. Uniform heating minimizes the temperature difference (delta T) between the surface and the core of the workpiece.

When a part's surface and core heat and cool at nearly the same rate, internal thermal stresses are kept to a minimum. This prevents the warping, twisting, and dimensional changes common in conventional heat treatment.

Cleaner, Brighter Surfaces

The vacuum environment itself, which necessitates radiation heating, prevents oxidation and other surface reactions.

Since there is no oxygen or reactive gas to contaminate the part at high temperatures, workpieces emerge from the furnace clean, bright, and free of scale.

Understanding the Trade-offs

While powerful, a radiation-dominant process has unique considerations that you must manage for successful outcomes.

Slower at Lower Temperatures

Radiation becomes a much more efficient mode of heat transfer as temperature increases. At lower temperatures, heating cycles in a vacuum can be slower than in a forced convection furnace.

"Line of Sight" is Critical

Radiation travels in straight lines. Any part of the workpiece that is "shadowed" by another part or by the furnace fixturing will not heat at the same rate.

Proper loading and spacing of parts are essential to ensure all critical surfaces have a clear line of sight to the heating elements or hot furnace walls. This is why maintaining a proper distance, as the references note, is so important.

Furnace Design is Paramount

The effectiveness of vacuum heating depends heavily on the furnace's design. The placement and quality of heating elements and the strategic use of heat shields are crucial for creating a uniform thermal field.

An improperly designed furnace can create zones of more or less intense radiation, negating the primary benefit of temperature uniformity.

How to Apply This to Your Project

Understanding that vacuum heating is radiation heating allows you to leverage its unique strengths for specific goals.

- If your primary focus is dimensional stability: Rely on vacuum heating for critical parts where minimizing distortion and warping is non-negotiable.

- If your primary focus is material purity: Use vacuum heating for reactive materials like titanium or superalloys that must remain free of surface oxides.

- If your primary focus is processing complex geometries: Leverage the uniform nature of radiation to ensure all features of an intricate part, both thick and thin, reach the target temperature consistently.

By grasping the physics of radiation, you can make deliberate choices that turn vacuum heat treatment from a simple process step into a strategic engineering advantage.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Heat Transfer Method | Thermal radiation via electromagnetic waves in a vacuum environment |

| Key Advantages | Unmatched temperature uniformity, reduced thermal stress and deformation, cleaner surfaces without oxidation |

| Key Considerations | Slower heating at lower temperatures, requires clear line of sight for uniform heating, dependent on furnace design |

| Ideal Applications | Critical parts requiring dimensional stability, reactive materials like titanium and superalloys, complex geometries needing consistent heating |

Ready to achieve superior heat treatment with advanced vacuum furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability