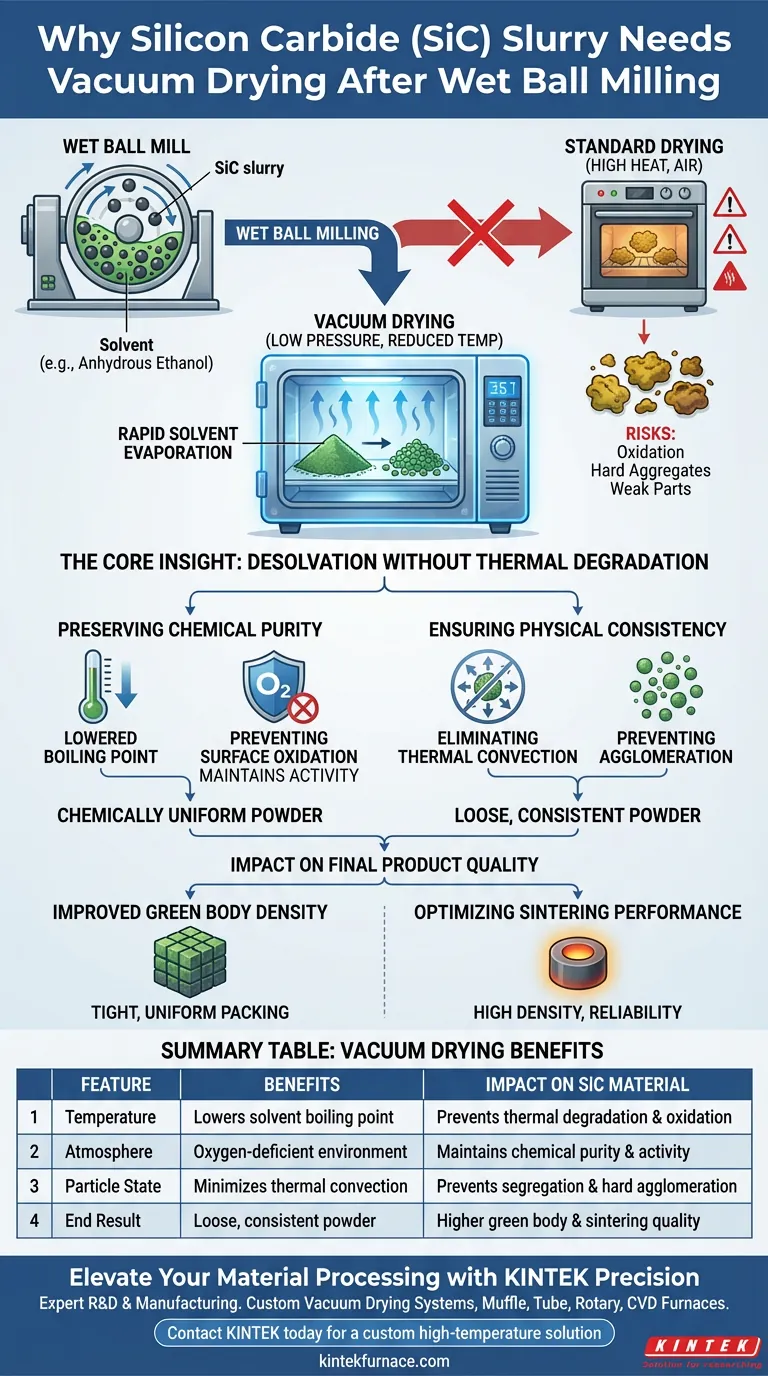

Vacuum drying is the critical process step required to preserve the chemical and physical integrity of Silicon Carbide (SiC) after wet ball milling. By creating a low-pressure environment, the vacuum oven lowers the boiling point of solvents—typically anhydrous ethanol—allowing them to evaporate rapidly at significantly reduced temperatures.

The Core Insight Vacuum drying solves the conflict between needing to remove solvents and needing to protect the material. It enables desolvation without thermal degradation, ensuring the SiC powder remains chemically active, loose, and chemically uniform for subsequent manufacturing stages.

Preserving Chemical Purity

Lowering the Boiling Point

The primary mechanism at work is the relationship between pressure and temperature. By reducing the pressure inside the chamber, the vacuum oven significantly lowers the boiling point of the solvent.

This allows the slurry to dry rapidly without requiring high heat input.

Preventing Surface Oxidation

Silicon Carbide is susceptible to surface oxidation when exposed to high temperatures in the presence of air. Standard drying methods often require heat levels that trigger this reaction.

Because vacuum drying operates at lower temperatures and in an oxygen-deficient environment, it effectively blocks surface oxidation. This maintains the initial activity and purity of the SiC powder.

Ensuring Physical Consistency

Eliminating Thermal Convection

High-temperature drying creates intense thermal convection currents within the slurry. These currents can cause particles to separate based on size or density (segregation).

Vacuum drying minimizes this thermal turbulence. This prevents segregation, ensuring the dried powder maintains consistent compositional integrity throughout the batch.

Preventing Agglomeration

When slurries are dried slowly or at high heat, particles tend to bind together, forming hard "agglomerates" that are difficult to break down later.

The rapid, low-temperature evaporation in a vacuum oven results in loose, dry precursor powders. This loose state is essential for avoiding severe secondary agglomeration.

Impact on Final Product Quality

Improving Green Body Density

The quality of the dried powder directly dictates the quality of the pressed part (the "green body").

By preventing hard agglomerates and oxidation, the vacuum process ensures the powder packs together tightly and uniformly during pressing. This leads to high green density and structural consistency.

Optimizing Sintering Performance

Consistent chemistry in the powder leads to consistent reactions during sintering.

By preserving the original chemical properties of the raw materials, vacuum drying ensures the final sintered body achieves high density and structural reliability.

The Risks of Standard Drying

While vacuum drying requires specialized equipment, attempting to bypass this step using standard thermal drying introduces significant quality risks.

The Cost of Oxidation

If conventional heating is used, the resulting surface oxidation acts as a contaminant. This often degrades the mechanical properties of the final ceramic, leading to weaker parts.

The Problem of Hard Aggregates

Without the gentle environment of the vacuum, powders can form hard clumps. These aggregates create voids or defects in the final product, compromising the structural integrity of the SiC component.

Making the Right Choice for Your Goal

To maximize the effectiveness of your SiC processing, consider your specific manufacturing objectives:

- If your primary focus is Chemical Purity: Ensure your vacuum system is capable of maintaining sufficiently low pressure to keep drying temperatures well below the oxidation threshold of SiC.

- If your primary focus is Mechanical Strength: Prioritize the "looseness" of the powder; a properly vacuum-dried powder should require minimal crushing before pressing to achieve high green density.

Vacuum drying is not just a drying step; it is a preservation step that defines the ultimate quality of your final ceramic product.

Summary Table:

| Feature | Vacuum Drying Benefits | Impact on SiC Material |

|---|---|---|

| Temperature | Lowers solvent boiling point | Prevents thermal degradation and oxidation |

| Atmosphere | Oxygen-deficient environment | Maintains chemical purity and powder activity |

| Particle State | Minimizes thermal convection | Prevents segregation and hard agglomeration |

| End Result | Loose, consistent powder | Higher green body density and sintering quality |

Elevate Your Material Processing with KINTEK Precision

Don’t let surface oxidation or hard agglomerates compromise your Silicon Carbide performance. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum drying systems, Muffle, Tube, Rotary, and CVD furnaces, all fully customizable to meet your unique lab requirements.

Ready to achieve superior powder consistency and high-density sintering results?

Contact KINTEK today for a custom high-temperature solution

Visual Guide

References

- Peroxymonosulfate Activation by Sludge-Derived Biochar via One-Step Pyrolysis: Pollutant Degradation Performance and Mechanism. DOI: 10.3390/w17172588

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What are the main differences between vacuum chambers and vacuum furnaces? Choose the Right Tool for Your Lab

- What are the required environmental conditions for operating a vacuum furnace? Ensure Safety and Optimal Performance

- Why is vacuum tempering considered faster than other methods? Discover the Key Speed and Efficiency Benefits

- How does vacuum hardening affect the hardness and surface layer of high-alloy tool steel? Boost Performance with Superior Heat Treatment

- What is the significance of the vacuum environment for sintering stainless steel? Unlock High-Density Purity

- Why are refractory metals like tungsten used in vacuum furnaces? Unlock High-Temp Performance Safely

- What role does vacuum annealing play in preventing material oxidation? Ensure Purity with Oxygen-Free Heat Treatment

- How does a precision vacuum system influence the sulfidation process of MoS2? Master Semiconductor Quality