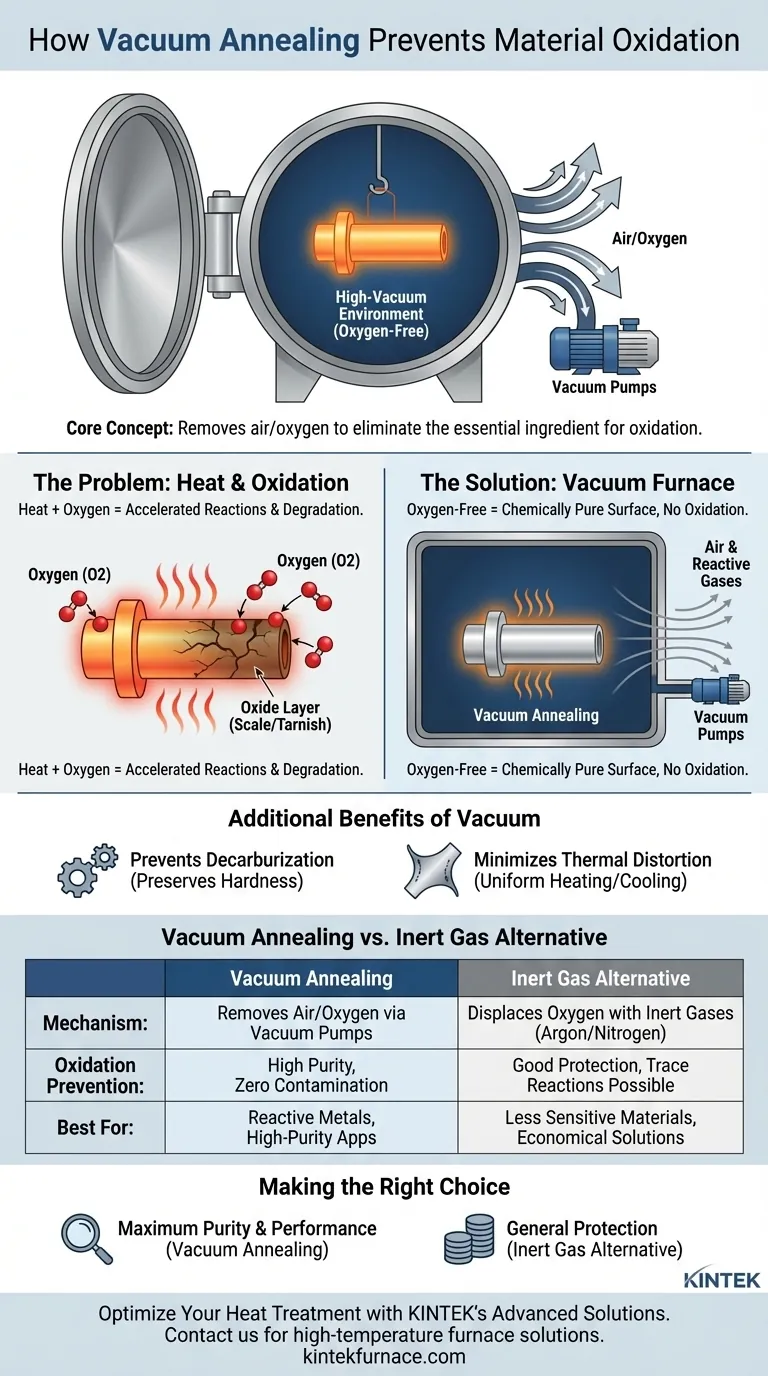

At its core, vacuum annealing prevents material oxidation by conducting the heat treatment process inside a high-vacuum chamber. By mechanically removing the air, specifically reactive gases like oxygen, the process eliminates the essential ingredient required for oxidation to occur, ensuring the material's surface remains pure and unaltered.

The challenge of any heat treatment is that elevated temperatures dramatically accelerate unwanted chemical reactions, like rust and scaling. Vacuum annealing solves this not by adding a protective layer, but by removing the atmospheric reactants—primarily oxygen—that cause degradation in the first place.

The Fundamental Problem: Heat and Oxidation

All heat treatment processes, including annealing, must manage the material's interaction with its environment. At high temperatures, this interaction becomes a significant engineering challenge.

Why Heat Accelerates Reactions

Heat acts as a catalyst for chemical reactions. As a metal's temperature increases, its atoms vibrate more energetically, making them far more susceptible to reacting with any gases present in the surrounding atmosphere.

The Role of Oxygen

Oxygen is highly reactive, especially with hot metals. When a hot metal surface is exposed to oxygen, they bond to form a layer of oxides (scale or tarnish). This oxide layer can degrade the material's mechanical properties, electrical conductivity, and surface finish.

How Vacuum Furnaces Provide the Solution

A vacuum furnace is an engineered system designed to create a precisely controlled, contamination-free environment for thermal processing.

Creating an Oxygen-Free Environment

The process begins by placing the material inside a sealed chamber. A powerful system of vacuum pumps then removes the air and other gases until an extremely low-pressure (high-vacuum) environment is achieved.

This act of physically removing the atmosphere starves the potential for an oxidation reaction. Without oxygen present, the metal's surface cannot oxidize, even at extreme temperatures.

Protecting Material Integrity

By preventing oxidation, the material remains chemically pure and maintains a bright, clean surface throughout the heating and cooling cycles. This is critical for high-performance applications where surface integrity is paramount.

The same principle is applied in related processes like vacuum brazing, where an oxygen-free environment ensures the filler metal flows cleanly, creating exceptionally strong and reliable joints free from impurities.

Understanding the Trade-offs and Alternatives

While highly effective, vacuum annealing is not the only method for controlling the atmosphere during heat treatment. Understanding the alternatives is key to making an informed decision.

The Inert Gas Alternative

An alternative approach is to replace the reactive air in a furnace with a non-reactive inert gas, such as argon or nitrogen. This process, known as an inert atmosphere purge, displaces the oxygen rather than removing it.

Vacuum vs. Inert Gas

A vacuum provides a higher degree of purity, as it actively removes virtually all gases. This makes it essential for highly reactive metals like titanium or for applications with zero tolerance for contamination.

An inert gas atmosphere is often a more cost-effective solution that provides sufficient protection for many common metals and processes where slight, trace-level reactions are acceptable.

Additional Benefits of a Vacuum

Beyond preventing oxidation, the controlled vacuum environment offers other advantages. It also prevents decarburization—the loss of carbon from the surface of steel—which preserves hardness. The slow, uniform heating and cooling in a vacuum also helps minimize thermal distortion and warping of parts.

Making the Right Choice for Your Application

Selecting the correct atmospheric control depends entirely on your material, your budget, and the required performance of the final component.

- If your primary focus is maximum purity and performance: Vacuum annealing is the definitive choice, especially for reactive metals or mission-critical components where any surface contamination is unacceptable.

- If your primary focus is general oxidation prevention for less sensitive materials: An inert gas atmosphere can provide excellent results and may be a more economical solution.

- If your primary focus is creating exceptionally clean and strong joints: Vacuum brazing utilizes the same principle to guarantee a contamination-free joining process.

Ultimately, choosing the right atmospheric control is about matching the precision of your process to the performance demands of your material.

Summary Table:

| Aspect | Vacuum Annealing | Inert Gas Alternative |

|---|---|---|

| Mechanism | Removes air and oxygen via vacuum pumps | Displaces oxygen with inert gases like argon or nitrogen |

| Oxidation Prevention | High purity, eliminates nearly all gases for zero contamination | Good protection, but may allow trace reactions |

| Best For | Reactive metals (e.g., titanium), high-purity applications | Less sensitive materials, cost-effective solutions |

| Additional Benefits | Prevents decarburization, minimizes thermal distortion | Simpler setup, often more economical |

Optimize Your Heat Treatment with KINTEK's Advanced Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need vacuum annealing for maximum purity or tailored systems for specific materials, we deliver reliable performance and enhanced efficiency.

Contact us today to discuss how our expertise can prevent oxidation and improve your material outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion