At its core, vacuum tempering is faster because its controlled environment enables more rapid and efficient heating and cooling cycles compared to traditional atmosphere-based methods. The process uses a specialized furnace to precisely manage temperature without the interference of oxygen, which fundamentally streamlines the entire operation from start to finish.

The true speed of vacuum tempering comes not just from a faster furnace cycle, but from the near elimination of post-processing steps. By preventing surface oxidation and minimizing distortion, it shortens the entire production workflow, delivering a finished part sooner.

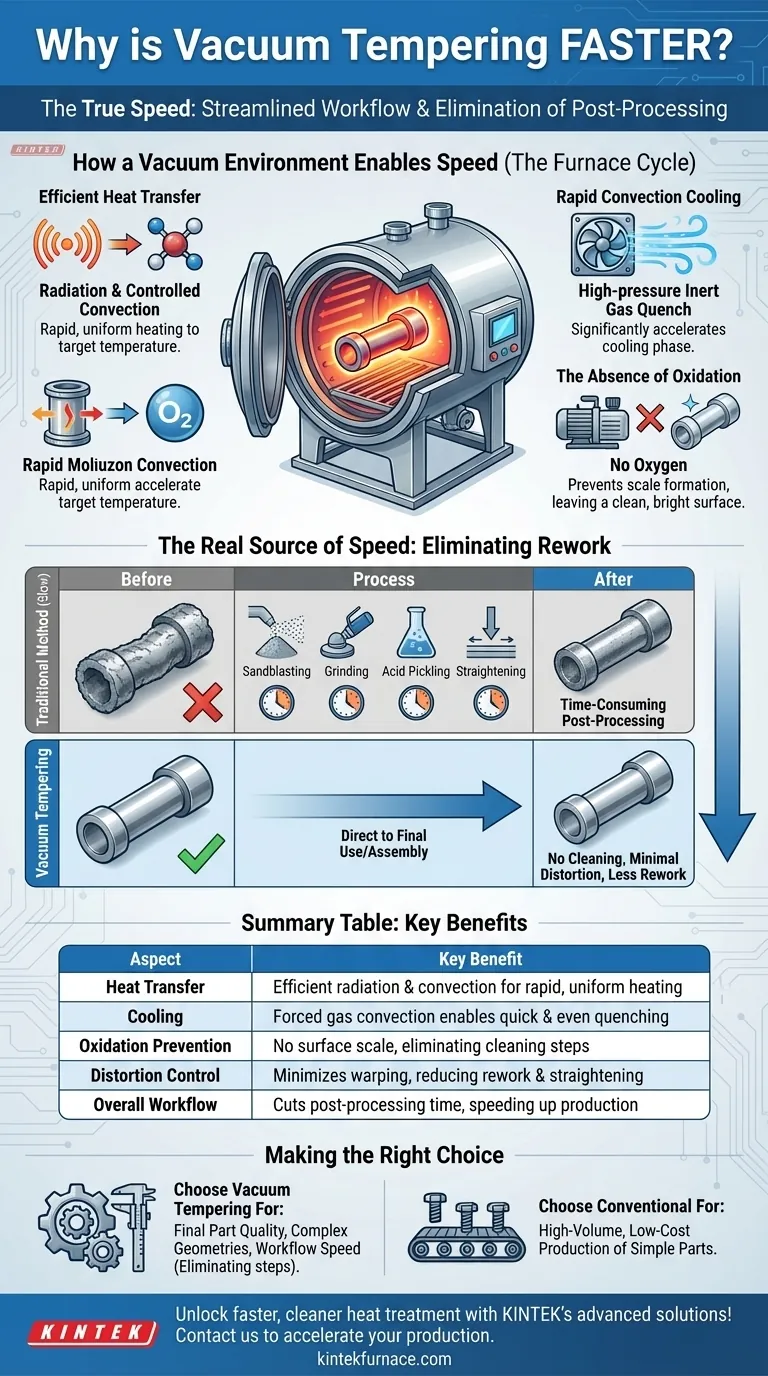

How a Vacuum Environment Enables Speed

The unique properties of a vacuum are central to the process's efficiency. By removing air and other gases, the furnace gains precise control over every variable, directly impacting the speed and quality of the temper.

Efficient Heat Transfer

In a vacuum furnace, heat is transferred primarily through radiation, which is highly efficient and uniform. For even faster heating cycles, the furnace can be backfilled with a high-purity inert gas, like nitrogen, to introduce controlled convection, ensuring the part reaches its target temperature quickly and evenly.

Rapid Convection Cooling

The cooling phase, or quenching, is significantly accelerated. After the tempering soak, a high-pressure stream of inert gas is circulated by a powerful fan inside the chamber. This forced convection process removes heat far more rapidly and uniformly than simply letting a part cool in open air, dramatically shortening the cycle time.

The Absence of Oxidation

Perhaps the most significant time-saver is the lack of oxygen. Traditional furnaces cause an oxide layer, or "scale," to form on the steel's surface. A vacuum environment prevents this entirely, leaving the part with a clean, bright, and unaltered surface.

The Real Source of Speed: Eliminating Rework

The speed advantage of vacuum tempering extends far beyond the furnace itself. The quality of the output directly reduces or eliminates entire stages of traditional manufacturing workflows.

No Need for Surface Cleaning

Because parts emerge from a vacuum furnace clean and free of scale, subsequent cleaning processes are rendered unnecessary. Time-consuming and labor-intensive steps like sandblasting, grinding, or acid pickling are completely avoided, shortening the path to a finished component.

Minimal Distortion and Rework

The uniform heating and controlled, even cooling minimize the internal stresses that cause parts to warp or distort. This high dimensional stability means less time is spent on costly and difficult straightening operations or remachining parts to bring them back into tolerance.

Understanding the Trade-offs

While fast and precise, vacuum tempering is not a universal solution. Understanding its limitations is key to making an informed decision.

Cycle Time vs. Overall Throughput

A single vacuum furnace cycle is highly efficient, but it is a batch process. For mass production of very simple, low-cost parts, a continuous belt furnace operating in a standard atmosphere may offer higher overall throughput, even if individual parts require more finishing.

Higher Initial Investment

Vacuum furnace technology is sophisticated and represents a significant capital investment compared to conventional furnaces. The cost is justified for high-value components where quality, precision, and a clean finish are non-negotiable.

Suitability for Specific Materials

The process is ideal for high-speed steels, tool steels, and specialty alloys that are sensitive to surface decarburization and oxidation. For simple carbon steels where surface finish is not critical, the benefits may not outweigh the higher operational cost.

Making the Right Choice for Your Goal

Selecting the right tempering method depends entirely on the requirements of your component and your production goals.

- If your primary focus is final part quality and complex geometries: Vacuum tempering is the superior choice, as it delivers exceptional surface finish and dimensional accuracy that reduces total manufacturing cost.

- If your primary focus is overall workflow speed: Choose vacuum tempering when eliminating post-processing steps like descaling and straightening provides the most significant time savings for your project.

- If your primary focus is high-volume, low-cost production: A conventional continuous furnace may be more economical for simple parts where surface oxidation can be tolerated or easily removed.

Ultimately, choosing the right heat treatment method is about aligning the process capabilities with your specific quality and efficiency requirements.

Summary Table:

| Aspect | Key Benefit |

|---|---|

| Heat Transfer | Efficient radiation and convection for rapid, uniform heating |

| Cooling | Forced gas convection enables quick and even quenching |

| Oxidation Prevention | No surface scale, eliminating cleaning steps |

| Distortion Control | Minimizes warping, reducing rework and straightening |

| Overall Workflow | Cuts post-processing time, speeding up production |

Unlock faster, cleaner heat treatment with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique needs, boosting efficiency and quality. Contact us today to discuss how our vacuum tempering technology can accelerate your production and reduce costs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today