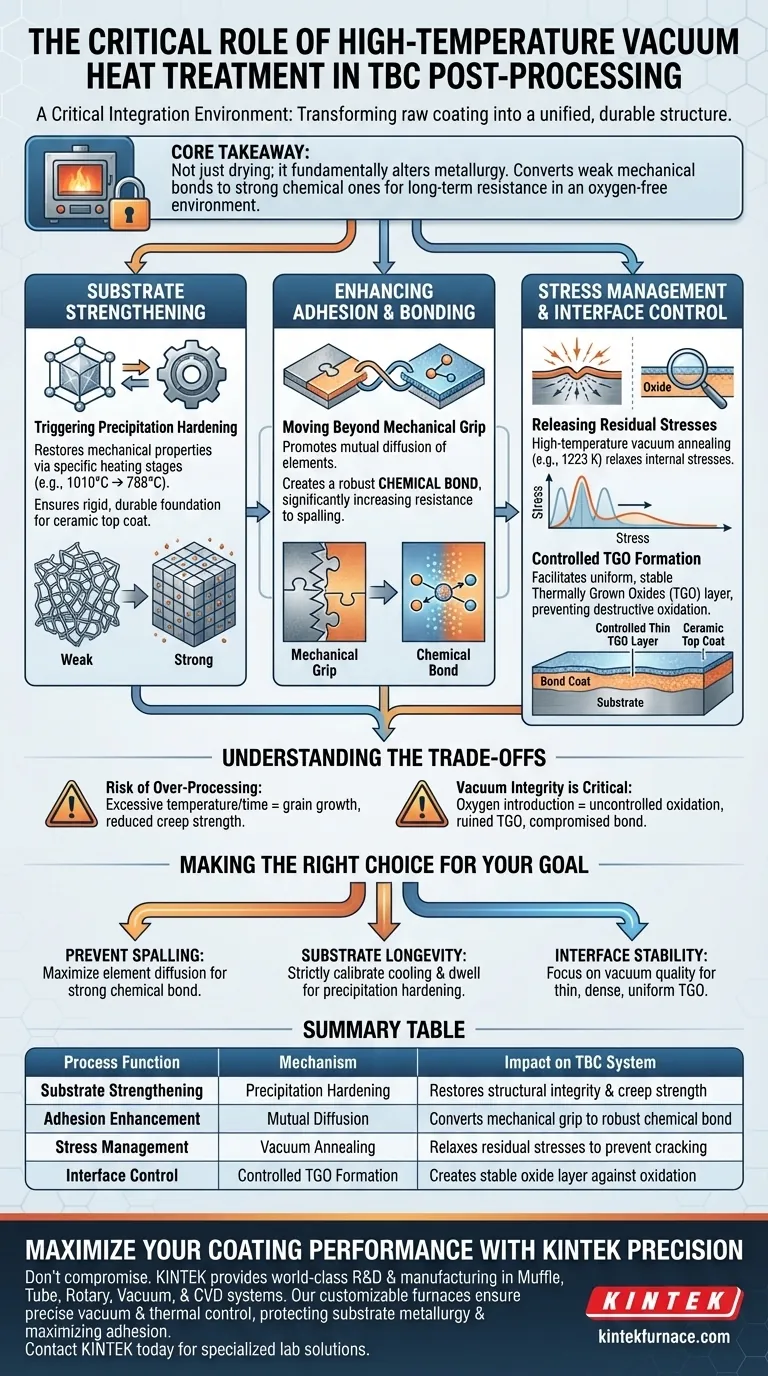

A high-temperature vacuum heat treatment furnace serves as the critical integration environment for thermal barrier coating (TBC) systems, transforming a raw, sprayed coating into a unified, durable structure. It functions primarily to strengthen the underlying substrate alloy through precipitation hardening while simultaneously relieving residual stresses and chemically bonding the coating to the surface through controlled diffusion.

Core Takeaway The vacuum furnace does not merely "dry" or "set" the coating; it fundamentally alters the metallurgy of the system. By precisely managing heat in an oxygen-free environment, it converts weak mechanical bonds into strong chemical ones and preconditions the interface for long-term thermal resistance.

The Mechanism of Substrate Strengthening

Triggering Precipitation Hardening

The application of high heat often affects the mechanical properties of the superalloy substrate. The vacuum furnace restores these properties by subjecting the components to specific heating stages, such as 1010 °C followed by 788 °C.

Restoring Structural Integrity

These specific thermal cycles trigger precipitation hardening mechanisms within the alloy. This ensures the substrate creates a rigid, durable foundation capable of supporting the ceramic top coat under extreme operational loads.

Enhancing Adhesion and Bonding

Moving Beyond Mechanical Grip

Initially, sprayed coatings rely heavily on mechanical interlocking—essentially "gripping" the surface roughness. Vacuum heat treatment promotes the mutual diffusion of elements between the coating and the substrate.

Creating a Chemical Bond

This diffusion process establishes a transitional bonding zone. This converts the initial mechanical interface into a robust chemical bond, which significantly increases the system's resistance to spalling (peeling off) during thermal cycling.

Stress Management and Interface Control

Releasing Residual Stresses

The coating process naturally generates high residual stresses that can lead to premature cracking. High-temperature vacuum annealing (at temperatures such as 1223 K) relaxes these stresses, bringing the internal phases of the coating into equilibrium.

Controlled TGO Formation

A critical function of the furnace is facilitating the initial formation of Thermally Grown Oxides (TGO).

Why the TGO Layer Matters

The TGO forms at the interface between the bond coat and the ceramic top coat. By initiating this layer in a controlled vacuum environment, the process ensures the oxide is uniform and stable, preventing rapid, destructive oxidation later during service.

Understanding the Trade-offs

The Risk of Over-Processing

While heat treatment is vital, precise control is non-negotiable. Excessive temperatures or prolonged exposure can lead to grain growth in the substrate, potentially reducing its creep strength.

Vacuum Integrity is Critical

The "vacuum" aspect is as important as the heat. Any introduction of oxygen during the high-temperature phase can lead to uncontrolled oxidation, ruining the TGO layer and compromising the bond strength before the part even enters service.

Making the Right Choice for Your Goal

To optimize your post-processing strategy, consider which failure mode you are most trying to prevent:

- If your primary focus is Preventing Spalling: Prioritize a heat treatment cycle that maximizes element diffusion to ensure a strong chemical bond replaces the mechanical interface.

- If your primary focus is Substrate Longevity: Ensure the cooling rates and dwell times are strictly calibrated to the specific precipitation hardening requirements of your superalloy composition.

- If your primary focus is Interface Stability: Focus on the vacuum quality to ensure the initial Thermally Grown Oxide (TGO) layer is thin, dense, and uniform.

Successful post-processing relies on balancing the thermal needs of the delicate ceramic coating with the hardening requirements of the robust metal substrate.

Summary Table:

| Process Function | Mechanism | Impact on TBC System |

|---|---|---|

| Substrate Strengthening | Precipitation Hardening | Restores structural integrity & creep strength of superalloys |

| Adhesion Enhancement | Mutual Diffusion | Converts mechanical grip into a robust chemical bond |

| Stress Management | Vacuum Annealing | Relaxes residual stresses to prevent premature cracking |

| Interface Control | Controlled TGO Formation | Creates a stable oxide layer to prevent destructive oxidation |

Maximize Your Coating Performance with KINTEK Precision

Don't let improper heat treatment compromise your thermal barrier systems. KINTEK provides world-class R&D and manufacturing expertise in Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically designed to handle the rigorous precipitation hardening and diffusion bonding required for advanced TBC post-processing.

Our customizable high-temp furnaces ensure precise vacuum integrity and thermal control, protecting your substrate's metallurgy while maximizing coating adhesion. Contact KINTEK today to discover how our specialized lab solutions can optimize your material performance and prevent costly spalling failures.

Visual Guide

References

- Madhura Bellippady, Nicolaie Markocsan. Performance of Atmospheric Plasma-Sprayed Thermal Barrier Coatings on Additively Manufactured Super Alloy Substrates. DOI: 10.3390/coatings14050626

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the function of a high-temperature annealing furnace for gold paste electrodes? Optimize Sensor Conductivity

- How does a heat treatment vacuum furnace work? Achieve Purity and Precision in Material Processing

- What role does a high-temperature vacuum furnace play in sintering magnesium composites? Key Success Factors

- What is the function of annealing furnaces in the manufacturing process of Indium Zinc Oxide (IZO) Thin Film Transistors (TFTs)? | Unlock High-Performance Electronics

- Why are laboratory vacuum furnaces vital for scientific research? Unlock Purity and Precision in Experiments

- Why is a high-temperature vacuum annealing furnace essential for graphene aerogels? Unlock Ultimate Conductivity

- What is the working process of a vacuum annealing furnace? Achieve Superior Material Quality with Precision Control

- What are vacuum furnaces used for? Achieve Unmatched Material Purity and Performance