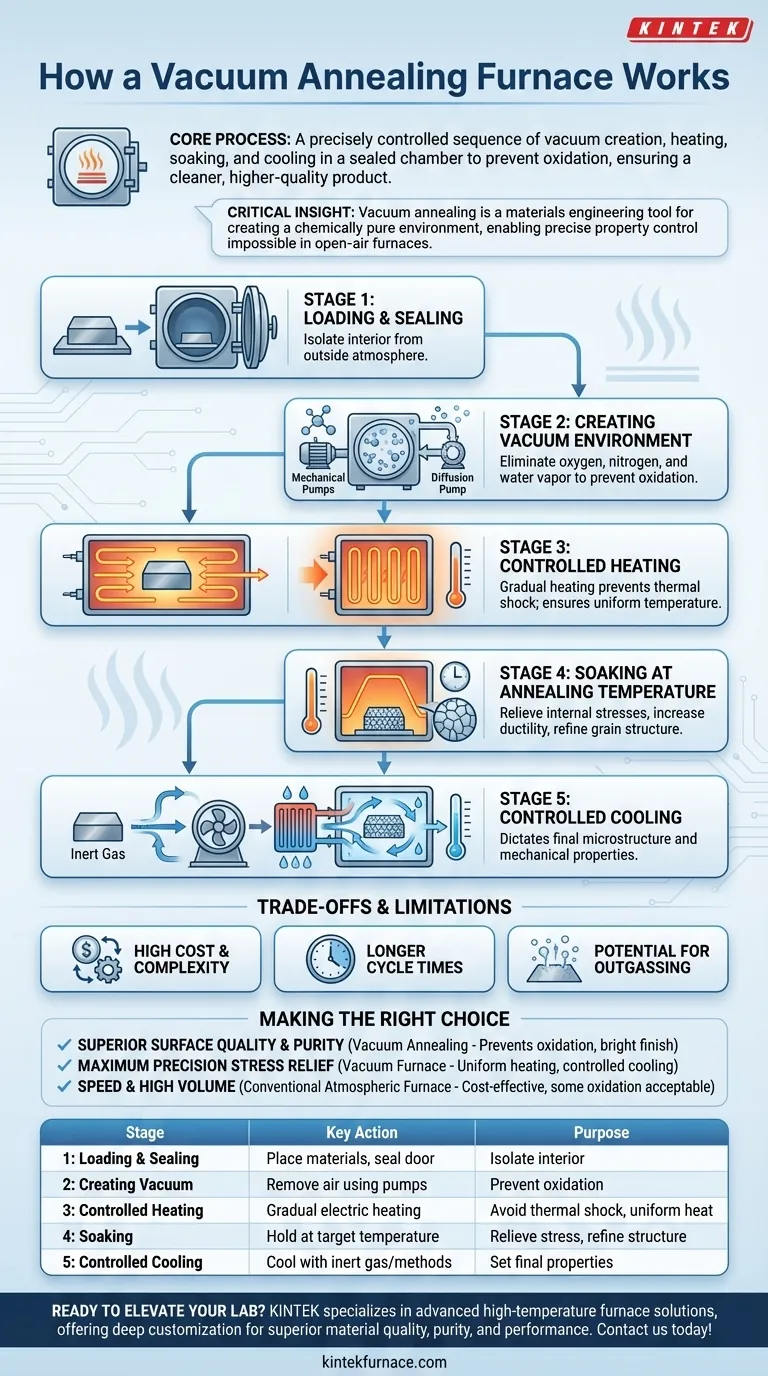

At its core, the working process of a vacuum annealing furnace is a precisely controlled sequence of creating a vacuum, heating the material, holding it at a specific temperature, and cooling it down. This entire process is conducted in a sealed chamber devoid of air to prevent surface reactions like oxidation, resulting in a cleaner and higher-quality final product.

The crucial insight is that vacuum annealing is not merely a heating and cooling process. It is a materials engineering tool that leverages a vacuum to create a chemically pure environment, enabling precise control over a material's final properties and surface finish in a way that is impossible in an open-air furnace.

A Step-by-Step Breakdown of the Process

The operation of a vacuum annealing furnace is a systematic cycle where each stage serves a distinct and critical purpose. Understanding this sequence reveals why this method is chosen for high-performance applications.

Stage 1: Loading and Sealing

Before the process can begin, the materials, typically metals or ceramics, are loaded into the furnace chamber. The furnace door is then sealed to create a vacuum-tight environment, isolating the interior from the outside atmosphere.

Stage 2: Creating the Vacuum Environment

This stage is what defines vacuum heat treatment. A vacuum system, often using a combination of mechanical pumps for an initial "rough" vacuum and diffusion or molecular pumps for a "high" vacuum, removes air and other gases from the chamber.

The fundamental purpose is to eliminate oxygen, nitrogen, and water vapor. Without these atmospheric gases, oxidation and other unwanted chemical reactions on the material's surface are prevented during the high-temperature heating cycle.

Stage 3: Controlled Heating

Once the desired vacuum level is reached, the heating system is activated. Electric heating elements inside the furnace raise the temperature of the material at a controlled, often gradual, rate.

This controlled ramp-up prevents thermal shock and ensures the entire workpiece heats uniformly, which is critical for achieving consistent material properties throughout the part.

Stage 4: Soaking at Annealing Temperature

When the material reaches the target annealing temperature, it is held there for a specified duration. This is known as the soaking or holding stage.

This period allows the material's internal crystalline structure to realign and homogenize, which relieves internal stresses, increases ductility, and refines the grain structure.

Stage 5: Controlled Cooling

After soaking, the heating elements are turned off and the cooling phase begins. This is another highly controlled stage that dictates the final microstructure and mechanical properties of the material.

Cooling can be slow, allowing the furnace to cool naturally. More commonly, a forced cooling system is used where a high-purity inert gas, such as nitrogen or argon, is introduced into the chamber. A high-power fan circulates this gas past a water-cooled heat exchanger, enabling rapid and uniform cooling.

Understanding the Trade-offs and Limitations

While powerful, a vacuum furnace is not the universal solution for all heat-treating needs. Acknowledging its trade-offs is key to making an informed decision.

High Initial Cost and Complexity

Vacuum furnaces and their associated pumping systems are significantly more expensive and complex than conventional atmospheric furnaces. They require specialized knowledge for operation and maintenance.

Longer Cycle Times

The process of pumping the chamber down to the required vacuum level adds considerable time to each cycle. For high-volume, low-margin parts, this can make the process less economical than continuous atmospheric heat treating.

Potential for Outgassing

Certain materials or surface contaminants can release trapped gases when heated in a vacuum, a phenomenon known as outgassing. This can interfere with achieving a high vacuum level and potentially contaminate the furnace interior.

Making the Right Choice for Your Goal

Selecting the right heat treatment process depends entirely on your desired outcome and the material's requirements.

- If your primary focus is superior surface quality and purity: Vacuum annealing is the definitive choice because it completely prevents oxidation, resulting in a bright, clean finish that requires no post-processing.

- If your primary focus is relieving internal stress with maximum precision: The uniform heating and highly controlled cooling cycles of a vacuum furnace offer unparalleled control over the final microstructure and properties.

- If your primary focus is speed and high-volume throughput for non-critical parts: A conventional atmospheric furnace may be more cost-effective, provided some level of surface oxidation is acceptable.

Ultimately, a vacuum annealing furnace provides an unmatched level of environmental control, transforming a simple heating process into a precise materials engineering tool.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1: Loading and Sealing | Place materials in chamber and seal door | Isolate interior from atmosphere |

| 2: Creating Vacuum | Remove air using pumps | Prevent oxidation and surface reactions |

| 3: Controlled Heating | Heat material gradually with electric elements | Avoid thermal shock and ensure uniform heating |

| 4: Soaking | Hold at target temperature | Relieve stress and refine grain structure |

| 5: Controlled Cooling | Cool with inert gas or natural methods | Set final microstructure and properties |

Ready to elevate your laboratory's capabilities with precision heat treatment? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, designed for diverse labs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring superior material quality, purity, and performance. Contact us today to discuss how our tailored solutions can benefit your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today