A high-temperature vacuum furnace serves as the critical consolidation environment used to transform a loose magnesium structure into a cohesive, durable scaffold.

During the second stage of sintering for porous magnesium-based composites, this furnace utilizes thermal energy (specifically around 400 °C) to drive diffusion bonding and the formation of sintering necks between magnesium particles. Simultaneously, the vacuum atmosphere plays a defensive role, suppressing the natural reactivity of magnesium to prevent excessive oxide layer growth, ensuring both mechanical strength and predictable biological degradation.

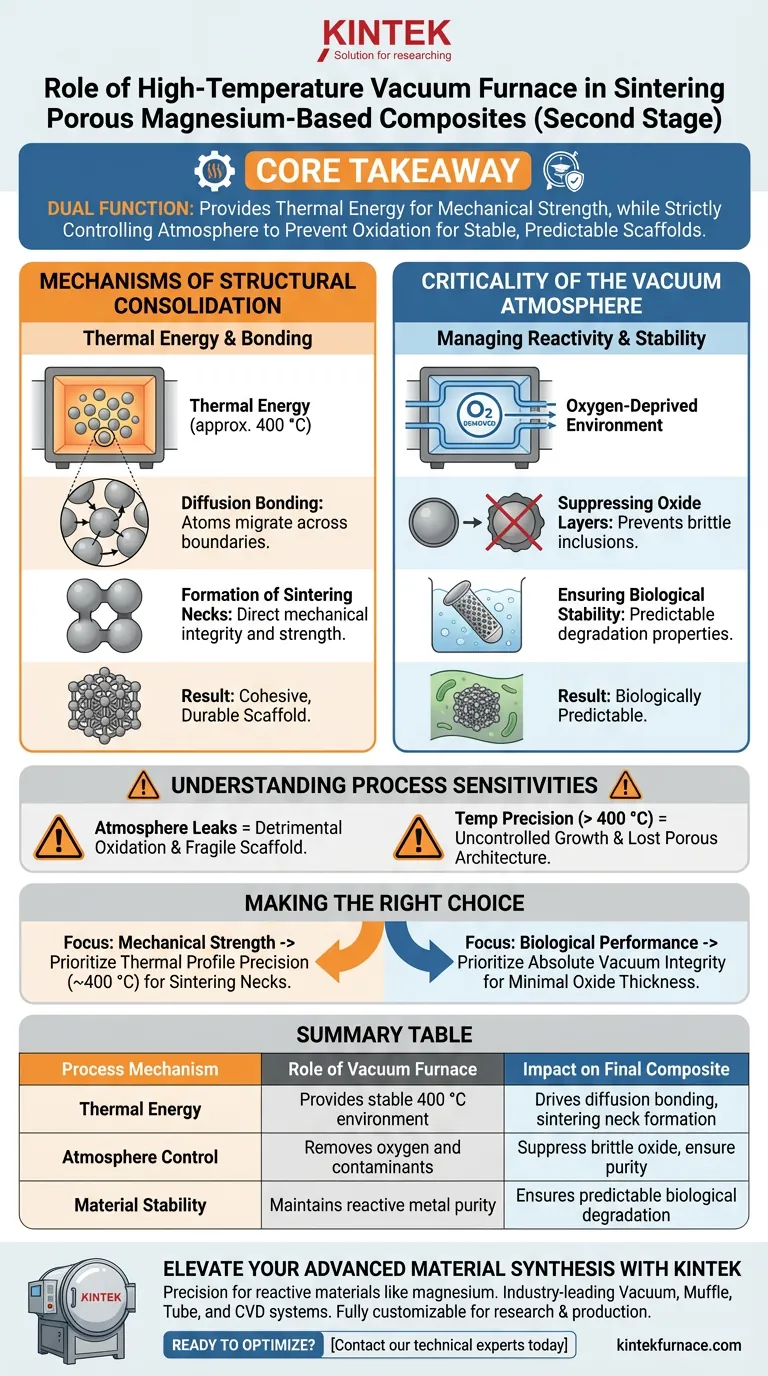

Core Takeaway The vacuum furnace performs a dual function: it provides the thermal energy necessary to physically fuse magnesium particles for mechanical strength, while strictly controlling the atmosphere to prevent oxidation. This balance is essential for creating a stable, high-strength porous scaffold that degrades predictably in biological environments.

Mechanisms of Structural Consolidation

The Role of Thermal Energy

The primary function of the furnace during this stage is to elevate the material to a specific sintering temperature, typically around 400 °C.

At this temperature, the magnesium particles do not melt completely; rather, they reach a state where atomic activity is high enough to facilitate bonding.

Diffusion Bonding

The thermal energy promotes diffusion bonding, a process where atoms migrate across particle boundaries.

This atomic movement is the fundamental mechanism that turns separate powder particles into a unified solid mass.

Formation of Sintering Necks

As diffusion progresses, connections known as sintering necks form at the contact points between magnesium particles.

The growth of these necks is directly responsible for the mechanical integrity of the porous scaffold, significantly increasing its overall strength.

The Criticality of the Vacuum Atmosphere

Managing Magnesium Reactivity

Magnesium is a highly reactive metal that oxidizes rapidly when exposed to oxygen, especially at high temperatures.

The vacuum furnace creates an oxygen-deprived environment that is essential for processing these reactive alloys safely and effectively.

Suppressing Oxide Layers

By removing oxygen, the vacuum environment effectively suppresses the excessive growth of oxide layers on the surface of the magnesium particles.

Uncontrolled oxidation would create brittle inclusions that weaken the material and inhibit the diffusion process described above.

Ensuring Biological Stability

For magnesium composites intended for biomedical use, the composition of the surface is vital.

By controlling oxide formation, the vacuum process ensures the stability of the material's structure and guarantees its biological degradation properties remain within design specifications.

Understanding Process Sensitivities

The Consequence of Atmosphere Leaks

Because magnesium is so reactive, even minor compromises in the vacuum level can lead to detrimental oxidation.

If the vacuum fails or is insufficient, the material may develop thick oxide shells that prevent the formation of sintering necks, resulting in a fragile scaffold that crumbles under stress.

Temperature Precision vs. Material Limits

While heat drives strength, the temperature must be capped strictly (e.g., near 400 °C) to avoid altering the magnesium's microstructure negatively.

Excessive heat could lead to uncontrolled grain growth or melting, destroying the porous architecture required for the application.

Making the Right Choice for Your Goal

To achieve the best results with porous magnesium-based composites, you must balance thermal input with atmospheric control.

- If your primary focus is mechanical strength: Prioritize the precision of the thermal profile (maintaining ~400 °C) to maximize the formation of sintering necks and diffusion bonding.

- If your primary focus is biological performance: Ensure the vacuum integrity is absolute to minimize oxide layer thickness, which dictates the material's degradation rate and stability.

Ultimately, the high-temperature vacuum furnace is not just a heater; it is a reaction-control chamber that dictates the final quality and safety of the magnesium composite.

Summary Table:

| Process Mechanism | Role of Vacuum Furnace | Impact on Final Composite |

|---|---|---|

| Thermal Energy | Provides stable 400 °C environment | Drives diffusion bonding and atom migration |

| Structural Growth | Facilitates sintering neck formation | Increases mechanical strength and integrity |

| Atmosphere Control | Removes oxygen and contaminants | Suppresses brittle oxide layer growth |

| Material Stability | Maintains reactive metal purity | Ensures predictable biological degradation |

Elevate Your Advanced Material Synthesis with KINTEK

Precision is non-negotiable when processing reactive materials like magnesium. KINTEK provides industry-leading Vacuum, Muffle, Tube, and CVD systems designed to meet the rigorous demands of specialized sintering.

Backed by expert R&D and world-class manufacturing, our lab high-temperature furnaces are fully customizable to your unique research or production needs. Whether you require absolute atmospheric integrity for biomedical scaffolds or precise thermal profiles for complex composites, KINTEK delivers the reliability you need to succeed.

Ready to optimize your sintering process? Contact our technical experts today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Divyanshu Aggarwal, Manoj Gupta. Porous Mg–Hydroxyapatite Composite Incorporated with Aloe barbadensis Miller for Scaphoid Fracture Fixation: A Natural Drug Loaded Orthopedic Implant. DOI: 10.3390/app14041512

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role does a vacuum heat treatment furnace play in the preparation of SKD6 side dies? Enhance Tool Steel Longevity

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the key features of a high-quality vacuum heat treatment furnace? Ensure Superior Heat Treatment Precision

- How are vacuum experimental furnaces used in research and laboratory settings? Unlock Precision in Materials Science

- Why is high-purity argon used to fill a vacuum furnace during diffusion coating? Prevent High-Temperature Oxidation

- How does the vacuum sintering furnace operate for sintering hard metals and alloys? Achieve High-Density, Pure Materials

- Why is a vacuum resistance furnace necessary for Ti-Zr-Nb alloy annealing? Ensure Purity & Uniformity

- Why is a high-temperature annealing furnace required for HP40Nb reformer tubes? Ensure Crack-Free Repair Welding