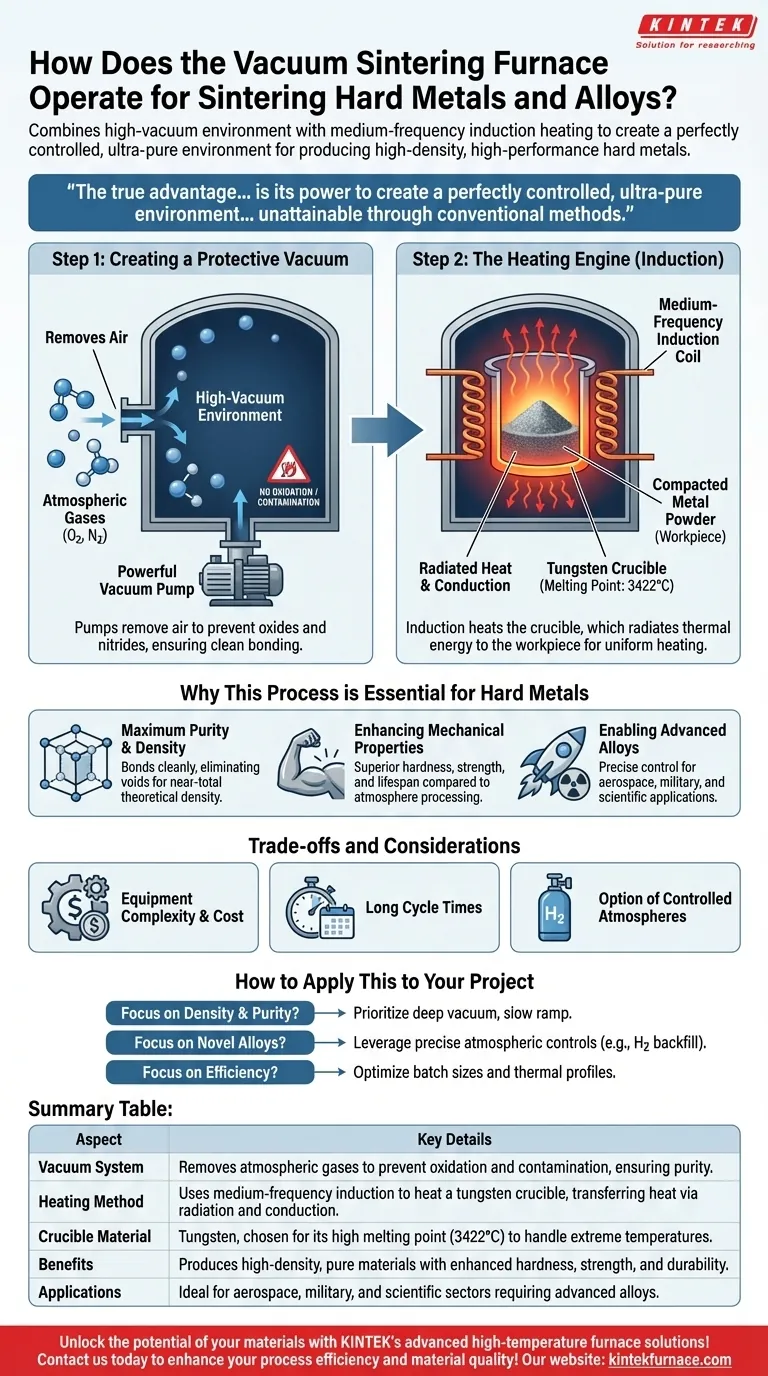

At its core, a vacuum sintering furnace operates by combining two key principles. It uses medium-frequency induction to heat a specialized crucible inside a sealed chamber, and it first creates a high-vacuum environment by removing all atmospheric gases. This intense, indirect heat is then radiated to the powdered hard metal, causing the particles to bond together, while the vacuum prevents the oxidation and contamination that would otherwise ruin the material at such extreme temperatures.

The true advantage of a vacuum sintering furnace isn't just its ability to generate high heat, but its power to create a perfectly controlled, ultra-pure environment. This combination is what enables the production of high-density, high-performance hard metals and alloys with properties unattainable through conventional methods.

The Two Pillars of Operation: Environment and Heat

The furnace's operation can be understood by examining its two fundamental systems: the vacuum system that creates the pristine environment and the induction system that provides the thermal energy.

The First Step: Creating a Protective Vacuum

Before any heating begins, powerful pumps remove the air from the furnace chamber. This step is non-negotiable for high-quality sintering.

This process removes oxygen, nitrogen, and other reactive gases. By eliminating them, the furnace prevents the formation of oxides and nitrides on the metal particles, which would inhibit proper bonding and compromise the final material's integrity.

The Heating Engine: Medium-Frequency Induction

Once the vacuum is established, the heating cycle begins using the principle of induction.

A high-frequency electrical current is passed through a coil that surrounds a tungsten crucible. This generates a powerful magnetic field, inducing electrical currents within the crucible itself, causing it to heat up rapidly to extremely high temperatures.

The workpiece, typically compacted metal powder, is not heated directly by the induction field. Instead, the white-hot crucible transfers thermal energy to the workpiece through radiation and conduction, ensuring uniform and controlled heating.

The Role of the Tungsten Crucible

The choice of a tungsten crucible is critical. Since the furnace is designed to sinter refractory metals like tungsten and molybdenum, the crucible must have a significantly higher melting point than the material being processed.

Tungsten's exceptionally high melting point (3422°C or 6192°F) makes it the ideal container for these demanding, high-temperature applications.

Why This Process is Essential for Hard Metals

Using a vacuum furnace is not just an option for hard metals; it is often a requirement for achieving the desired performance characteristics used in aerospace, military, and scientific applications.

Achieving Maximum Purity and Density

The vacuum environment ensures no impurities are introduced during the process. This allows the metal particles to bond cleanly, eliminating internal voids and resulting in a final product with near-total theoretical density.

Enhancing Mechanical Properties

A dense, pure, and oxide-free metallic structure directly translates to superior mechanical properties. The final sintered components exhibit enhanced hardness, strength, and overall functional lifespan compared to materials processed in atmosphere.

Enabling the Creation of Advanced Alloys

This precise control over atmosphere and temperature is what allows for the creation of special alloys with unique properties. Materials for nuclear reactors or aerospace components often depend on the contaminant-free environment that only a vacuum furnace can provide.

Understanding the Trade-offs and Considerations

While highly effective, vacuum sintering involves specific operational realities and constraints that must be understood.

Equipment Complexity and Cost

Vacuum sintering furnaces are sophisticated pieces of equipment. The need for robust vacuum pumps, precise power controllers, and high-temperature-resistant components makes them a significant capital investment.

Long Cycle Times

The process is inherently a batch operation, not a continuous one. A full cycle involves loading, evacuating the chamber, slowly ramping up the temperature, holding it for the sintering duration, and then cooling down—all of which can take many hours.

The Option of Controlled Atmospheres

For certain applications, after the initial vacuum is created, the furnace can be backfilled with a specific protective or reactive gas, such as hydrogen. This creates a "controlled atmosphere" which can help to actively remove surface oxides and further enhance the sintering process for specific alloys.

How to Apply This to Your Project

The specific operational parameters you choose will depend entirely on the desired outcome for your final component.

- If your primary focus is achieving maximum material density and purity: You must prioritize a deep, stable vacuum throughout the heating cycle and utilize a slow, uniform temperature ramp.

- If your primary focus is developing novel or sensitive alloys: You should leverage the furnace's precise atmospheric controls, potentially using an inert gas backfill or a reactive gas like hydrogen to influence the material's final chemistry.

- If your primary focus is process efficiency: You need to optimize batch sizes and carefully profile the heating and cooling curves to minimize cycle time without introducing thermal stress or compromising the final quality.

Ultimately, mastering the interplay between the vacuum level, temperature profile, and atmospheric composition is the key to unlocking the full potential of advanced sintered components.

Summary Table:

| Aspect | Key Details |

|---|---|

| Vacuum System | Removes atmospheric gases to prevent oxidation and contamination, ensuring purity. |

| Heating Method | Uses medium-frequency induction to heat a tungsten crucible, transferring heat via radiation and conduction. |

| Crucible Material | Tungsten, chosen for its high melting point (3422°C) to handle extreme temperatures. |

| Benefits | Produces high-density, pure materials with enhanced hardness, strength, and durability. |

| Applications | Ideal for aerospace, military, and scientific sectors requiring advanced alloys. |

Unlock the potential of your materials with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum sintering furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for sintering hard metals and alloys. Contact us today to discuss how we can enhance your process efficiency and material quality!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability