A vacuum heat treatment furnace serves as the definitive environment for hardening SKD6 tool steel, specifically by heating the material to approximately 1030°C in an oxygen-free chamber. Its primary function is to prevent surface defects such as oxidation and decarburization while utilizing programmed multi-stage cooling to lock in the material's ideal mechanical properties.

Core Takeaway: The vacuum furnace is not merely a heater; it is a protective preservation system. By removing air, it prevents chemical degradation of the steel surface, while its precise cooling capabilities ensure the SKD6 die achieves the necessary hardness and structural uniformity required for high-stress applications.

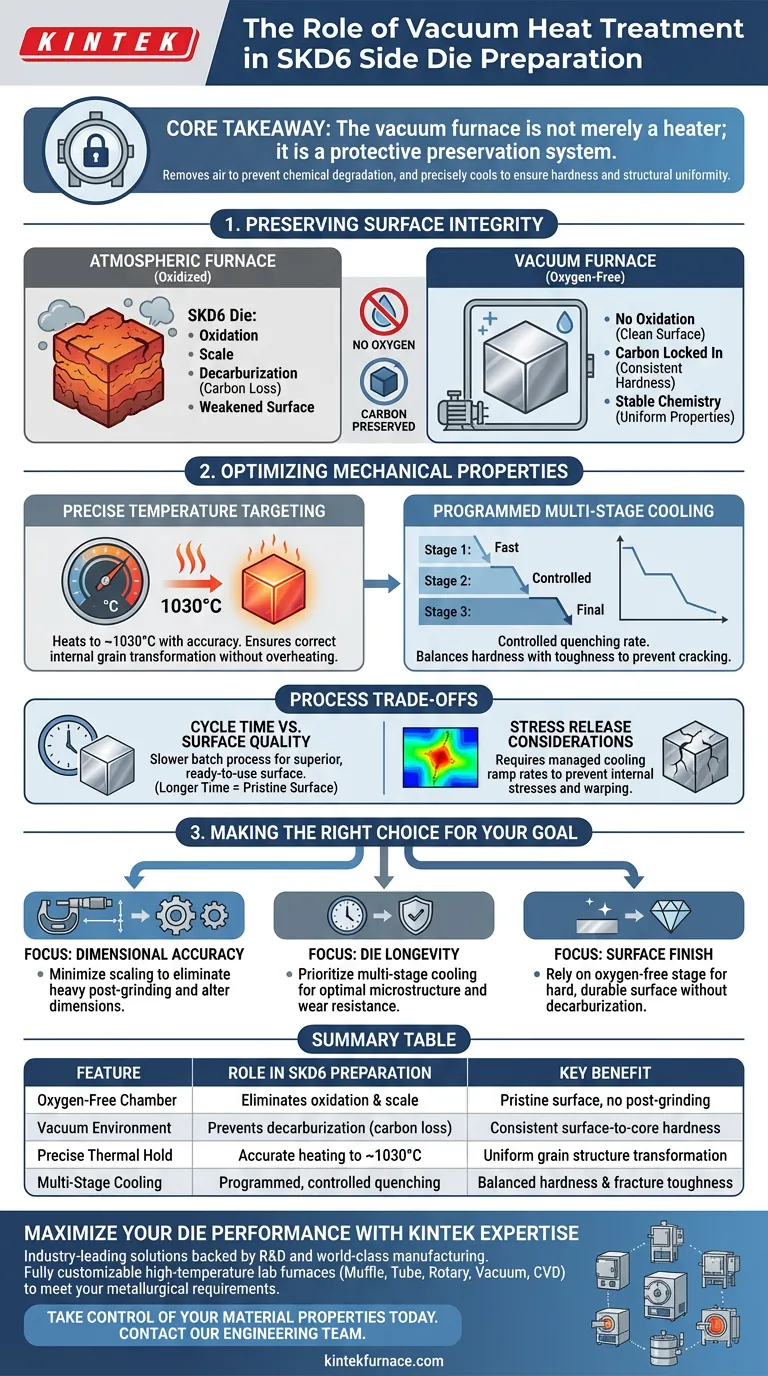

Preserving Surface Integrity

Creating an Oxygen-Free Environment

The most immediate role of the vacuum furnace is the total exclusion of oxygen during the heating cycle.

By operating in a vacuum, the furnace prevents oxygen from reacting with the SKD6 steel surface. This eliminates the formation of oxide scales, ensuring the die comes out of the furnace as clean as it went in.

Preventing Decarburization

High temperatures typically cause carbon to migrate out of steel when exposed to air, weakening the surface layer (decarburization).

The vacuum environment blocks this chemical reaction entirely. This ensures the carbon content—which is vital for hardness—remains consistent from the core of the die all the way to the exterior surface.

Ensuring Chemical Consistency

Because unwanted chemical reactions are halted, the composition of the SKD6 material remains stable.

This stability guarantees that the mechanical properties are uniform throughout the die. It eliminates "soft spots" or brittle areas that could lead to premature failure during use.

Optimizing Mechanical Properties

Precise Temperature Targeting

SKD6 tool steel requires a specific austenitizing temperature to prepare its internal structure for hardening.

The vacuum furnace maintains a precise thermal hold, typically around 1030°C. This accuracy is critical to ensure the steel’s internal grain structure transforms correctly without overheating.

Programmed Multi-Stage Cooling

Heating is only half the battle; the "quenching" (cooling) process dictates the final hardness.

The furnace utilizes a programmed, multi-stage cooling process. By controlling the rate at which the die cools, the furnace maximizes the steel's mechanical properties, balancing hardness with toughness to prevent cracking.

Understanding Process Trade-offs

Cycle Time vs. Surface Quality

While vacuum heat treatment produces superior surface quality, it is generally a slower batch process compared to continuous atmospheric furnaces.

The "trade-off" is accepting a longer processing time to achieve a pristine surface that requires little to no post-treatment machining or cleaning.

Stress Release Considerations

While the primary goal is hardening, the thermal cycle also impacts residual stresses.

Proper management of the heating and cooling ramp rates is essential to release internal stresses without introducing new thermal shock. If the cooling stage is too aggressive or uncontrolled, it can introduce warping, negating the benefits of the clean vacuum environment.

Making the Right Choice for Your Goal

To apply this to your manufacturing process, consider your specific requirements for the side dies:

- If your primary focus is Dimensional Accuracy: Utilize the vacuum furnace to minimize surface scaling, which eliminates the need for heavy post-heat-treatment grinding that could alter dimensions.

- If your primary focus is Die Longevity: Prioritize the programmed multi-stage cooling capabilities to ensure the steel achieves the optimal microstructure for wear resistance.

- If your primary focus is Surface Finish: Rely on the oxygen-free vacuum stage to prevent decarburization, ensuring the surface is as hard and durable as the core.

A vacuum heat treatment furnace transforms SKD6 from raw steel into a high-performance precision tool by strictly controlling its chemical and thermal environment.

Summary Table:

| Feature | Role in SKD6 Preparation | Key Benefit |

|---|---|---|

| Oxygen-Free Chamber | Eliminates oxidation and scale formation | Pristine surface finish, no post-grinding |

| Vacuum Environment | Prevents decarburization (carbon loss) | Consistent surface-to-core hardness |

| Precise Thermal Hold | Accurate heating to ~1030°C | Uniform grain structure transformation |

| Multi-Stage Cooling | Programmed, controlled quenching | Balanced hardness and fracture toughness |

Maximize Your Die Performance with KINTEK Expertise

Don't let surface defects or improper cooling compromise your SKD6 tools. KINTEK provides industry-leading vacuum heat treatment solutions backed by expert R&D and world-class manufacturing. Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to meet your unique metallurgical requirements.

Take control of your material properties today. Contact our engineering team to discuss how our precision systems can enhance your manufacturing efficiency.

Visual Guide

References

- Herry Patria, Dianta Mustofa Kamal. Enhancing side die resistance to thermal shock in automotive casting: a comparative study of FCD550 and SKD6 materials. DOI: 10.15587/1729-4061.2024.306615

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a high-temperature vacuum furnace benefit vacuum heat treatment and sintering processes? Unlock Superior Material Quality

- What are the key components of a vacuum sintering furnace? Essential Parts for Precision Material Processing

- What is the primary function of a laboratory vacuum oven in the synthesis of ABC triblock copolymers? Ensure Purity.

- Why is a vacuum drying oven necessary during the preparation of TiOx@C precursors? Enhance Material Structural Integrity

- What is the primary function of a vacuum furnace? Achieve Purity and Precision in Heat Treatment

- What types of heating elements are used in laboratory vacuum furnaces and how do they function? Optimize Your High-Temp Processes

- What are the essential requirements for a high-temperature vacuum furnace? Optimize Your Metal Solidification Research

- What are the technical advantages of vacuum Spark Plasma Sintering (SPS) systems? Advanced SiC Ceramic Densification