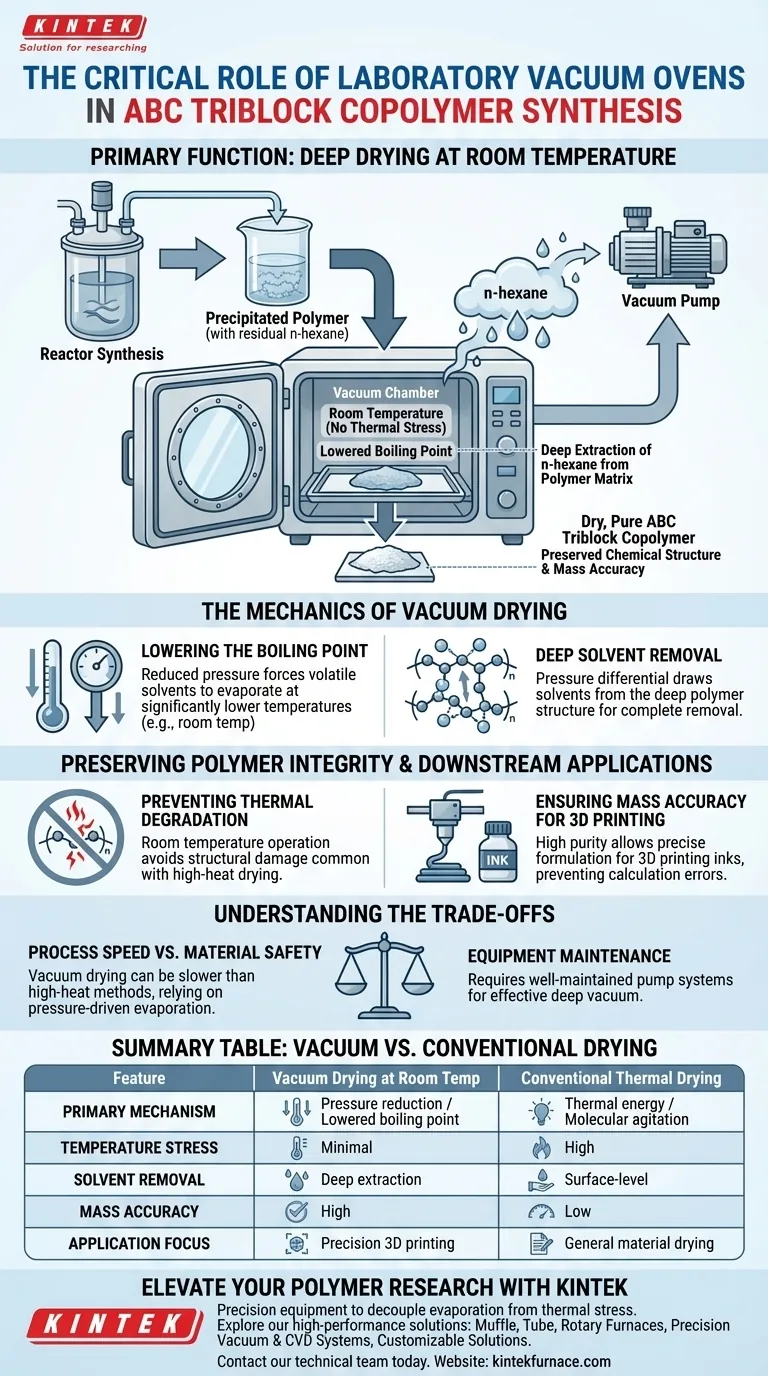

The primary function of a laboratory vacuum oven in the synthesis of ABC triblock copolymers is the deep drying of the precipitated polymer. This process is specifically designed to remove residual solvents, such as n-hexane, from the polymer matrix. By operating under vacuum conditions at room temperature, the oven ensures the polymer is dried thoroughly without being exposed to thermal stress.

Core Takeaway: Vacuum drying decouples the process of evaporation from high heat. This critical separation ensures the polymer retains its original chemical structure and mass accuracy, preventing degradation that would compromise downstream applications like 3D printing inks.

The Critical Role of Vacuum Conditions

Lowering the Boiling Point

The fundamental advantage of using a vacuum oven is its ability to lower the boiling point of solvents.

By reducing the pressure surrounding the polymer, the vacuum environment forces volatile solvents to evaporate at much lower temperatures.

This allows for effective drying without the need to heat the chamber, which is the standard method in non-vacuum ovens.

Deep Removal of Solvents

In the specific case of ABC triblock copolymers, the goal is to remove residual n-hexane.

Solvents trapped deep within the polymer matrix can be difficult to extract under standard atmospheric pressure.

The vacuum environment creates a pressure differential that draws these trapped solvents out from the "deep" structure of the material, ensuring the final product is solvent-free.

Preserving Polymer Integrity

Preventing Thermal Degradation

The most significant risk during the drying phase of polymer synthesis is heat damage.

The primary reference highlights that this process occurs at room temperature to avoid the structural changes or degradation often caused by heating.

While other materials (like electrode sheets or catalysts) may tolerate temperatures of 60°C to 90°C, ABC triblock copolymers require a strictly non-thermal approach to maintain their molecular architecture.

Ensuring Mass Accuracy

Accurate mass measurement is vital for the subsequent preparation of 3D printing inks.

If a polymer degrades or retains invisible solvent weight, the concentration calculations for the ink formulation will be incorrect.

Deep vacuum drying guarantees high purity, allowing for precise formulation based on the true mass of the polymer components.

Understanding the Trade-offs

Process Speed vs. Material Safety

While vacuum drying is safer for the material, it can be a slower process compared to high-heat drying methods.

Operating at room temperature relies entirely on the vacuum pressure to drive evaporation, which may take longer than methods that utilize thermal energy to accelerate molecular movement.

Equipment Maintenance

Achieving the necessary "deep" vacuum requires a well-maintained pump system.

If the vacuum seal is compromised or the pump is underpowered, the solvent removal will be incomplete, negating the benefits of the process and potentially leaving impurities in the polymer.

Making the Right Choice for Your Synthesis

To ensure the success of your ABC triblock copolymer synthesis, apply the vacuum oven based on your specific purity requirements.

- If your primary focus is Structural Integrity: strict adherence to room temperature settings is required to prevent polymer chain degradation.

- If your primary focus is Ink Formulation: ensure the drying cycle is long enough to achieve complete solvent removal, guaranteeing the mass accuracy needed for precise 3D printing recipes.

Ultimately, the vacuum oven serves as a preservation tool, ensuring that the chemistry you synthesized in the reactor is exactly what you recover after drying.

Summary Table:

| Feature | Vacuum Drying at Room Temp | Conventional Thermal Drying |

|---|---|---|

| Primary Mechanism | Pressure reduction / Lowered boiling point | Thermal energy / Molecular agitation |

| Temperature Stress | Minimal (Room Temperature) | High (Risk of degradation) |

| Solvent Removal | Deep extraction of n-hexane | Surface-level evaporation |

| Mass Accuracy | High (Pure polymer) | Low (Residual solvent or mass loss) |

| Application Focus | Precision 3D printing inks | General material drying |

Elevate Your Polymer Research with KINTEK

Precision in ABC triblock copolymer synthesis demands equipment that can decouple evaporation from thermal stress. KINTEK provides advanced, high-performance vacuum ovens designed to maintain the structural integrity of your most sensitive materials.

Backed by expert R&D and manufacturing, we offer a comprehensive range of laboratory high-temperature and vacuum systems, including:

- Muffle, Tube, and Rotary Furnaces

- Precision Vacuum & CVD Systems

- Customizable Solutions tailored for unique synthesis and 3D printing ink requirements.

Ensure your synthesized chemistry remains pristine from reactor to recovery. Contact our technical team today to find your perfect laboratory drying solution.

Visual Guide

References

- Xu Liu, Theoni K. Georgiou. Graphene inks for printing based on thermoresponsive ABC triblock terpolymer gels. DOI: 10.1039/d5lp00071h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How is temperature controlled during the heating process in a vacuum furnace? Unlock Precision for High-Integrity Processes

- What is the function of introducing 150 Pa of argon gas into a furnace during the vacuum refining of AM60 magnesium alloy?

- Why is vacuum-pressure treatment equipment required for deep wood impregnation? Unlock Ultimate Material Durability

- How does heat loss occur in vacuum furnace insulation? Two Pathways Draining Efficiency

- Why is a vacuum heater used to preheat the deposition chamber? Enhance Coating Adhesion & Purity

- What are the primary benefits of vacuum heat treatment technology? Achieve Superior Metallurgical Control and Quality

- Why is a laboratory high-temperature furnace equipped with a high-vacuum system essential for metal-slag reactions?

- What are the typical vacuum levels for medium, high, and ultra-high vacuum furnaces? Optimize Your Process Efficiency