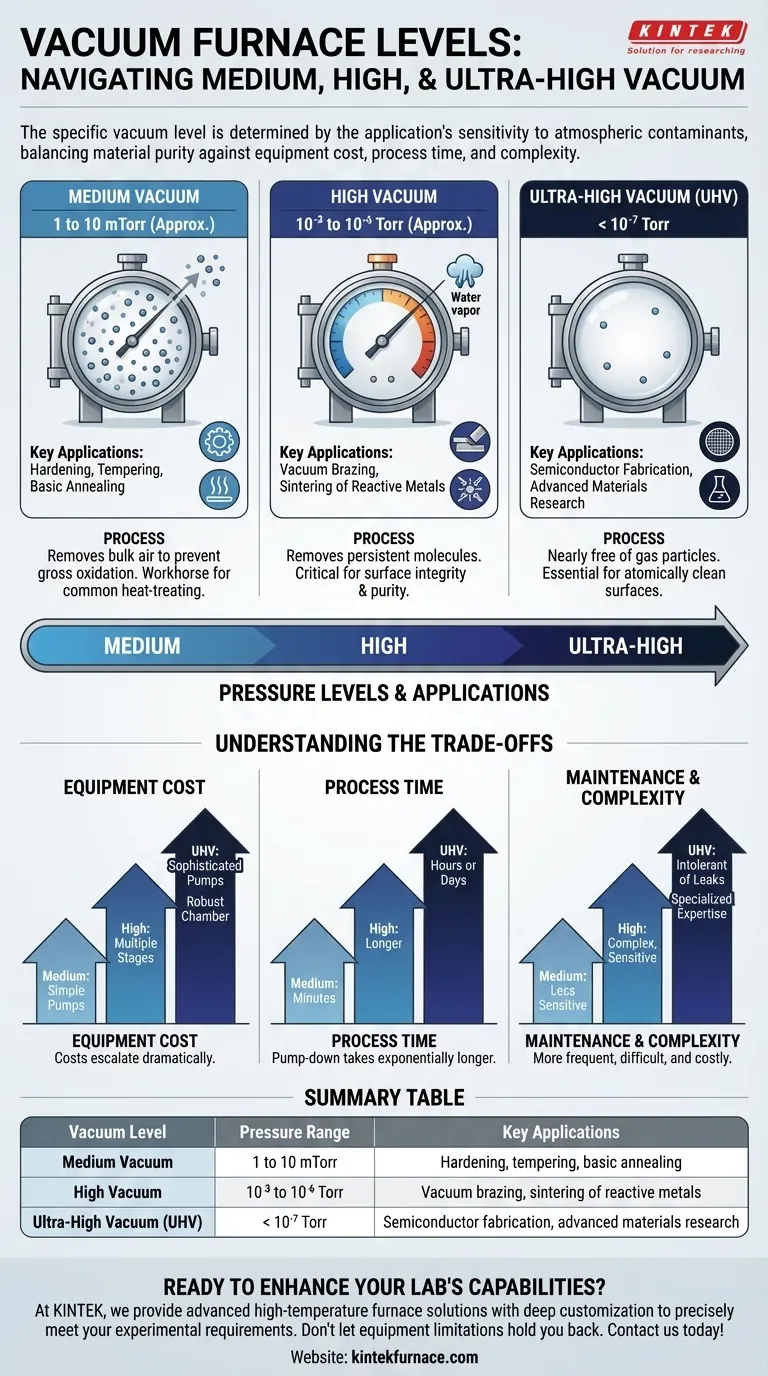

In a vacuum furnace, the classifications for vacuum levels are quite specific. A medium vacuum typically operates between 1 and 10 millitorr (mTorr), a high vacuum ranges from 10⁻³ to 10⁻⁶ Torr, and an ultra-high vacuum (UHV) is achieved at pressures of 10⁻⁷ Torr or lower. These levels are not arbitrary; they are directly tied to the metallurgical or chemical process being performed within the furnace.

The specific vacuum level required is determined by the application's sensitivity to atmospheric contaminants. Choosing the correct level is a critical engineering decision, balancing the need for material purity against significant increases in equipment cost, process time, and operational complexity.

Matching Vacuum Level to Process Requirements

The primary purpose of a vacuum is to remove atmospheric gases—primarily oxygen, nitrogen, and water vapor—that could react with the materials being heated. The degree to which these gases must be removed dictates the necessary vacuum level.

Medium Vacuum (Approx. 1 to 10 mTorr)

A medium vacuum is sufficient for removing the vast majority of air from the chamber. This prevents the gross oxidation and discoloration that would occur if materials were heated in open air.

This level is the workhorse for many common heat-treating processes like hardening, tempering, and basic annealing. For these applications, the goal is to achieve the desired mechanical properties without significant surface contamination.

High Vacuum (Approx. 10⁻³ to 10⁻⁶ Torr)

Moving to a high vacuum removes not just the bulk atmosphere but also the more persistent molecules, especially water vapor. This creates a significantly cleaner environment.

This level is critical for processes where surface integrity and purity are paramount. Applications include high-purity vacuum brazing, where oxides would prevent a proper bond, and vacuum sintering, where a clean environment is needed for particles to fuse correctly.

Ultra-High Vacuum (UHV) (<10⁻⁷ Torr)

UHV creates an environment that is nearly free of gas particles. At these pressures, the time it takes for a single layer of gas molecules to form on a clean surface can extend from seconds (in high vacuum) to hours.

This extreme level of purity is non-negotiable for the most sensitive applications. It is essential for semiconductor manufacturing, advanced materials research, and processes requiring atomically clean surfaces to prevent even the slightest contamination.

Understanding the Trade-offs

Achieving a lower pressure is not always better. The pursuit of a higher vacuum comes with significant operational and financial consequences, making it crucial to choose only the level required for your process.

Equipment Cost

The cost of a vacuum system escalates dramatically with each tier. A medium vacuum can be achieved with relatively simple pumps, but high and ultra-high vacuum levels require multiple, sophisticated pump stages (like turbomolecular or cryogenic pumps) and more robust chamber construction, leading to much higher capital investment.

Process Time

Reaching lower pressures takes exponentially longer. The "pump-down" time to achieve a medium vacuum might be minutes, but reaching UHV can take many hours or even days. This directly impacts throughput and operational efficiency.

Maintenance and Complexity

High and UHV systems are far more complex and sensitive. They are intolerant of leaks, require specialized cleaning procedures, and demand a higher level of operator expertise. Maintenance is more frequent, more difficult, and more costly than for medium vacuum systems.

Making the Right Choice for Your Goal

Your process requirements should be the sole driver of your vacuum level selection. Over-specifying a vacuum level leads to unnecessary expense and complexity, while under-specifying it will result in failed processes.

- If your primary focus is general heat treatment (hardening, tempering, stress relief): A medium vacuum furnace is typically sufficient and the most cost-effective choice.

- If your primary focus is high-purity brazing, sintering, or annealing of reactive metals: A high vacuum furnace is necessary to prevent oxidation and ensure process integrity.

- If your primary focus is semiconductor fabrication, surface science, or advanced materials research: An ultra-high vacuum system is the only option to achieve the required purity.

Ultimately, understanding these distinct vacuum regimes empowers you to select a system that meets your technical goals without exceeding your operational constraints.

Summary Table:

| Vacuum Level | Pressure Range | Key Applications |

|---|---|---|

| Medium Vacuum | 1 to 10 mTorr | Hardening, tempering, basic annealing |

| High Vacuum | 10⁻³ to 10⁻⁶ Torr | Vacuum brazing, sintering of reactive metals |

| Ultra-High Vacuum (UHV) | <10⁻⁷ Torr | Semiconductor fabrication, advanced materials research |

Ready to enhance your lab's capabilities with the right vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether for general heat treatment, high-purity processes, or cutting-edge research. Don't let equipment limitations hold you back—contact us today to discuss how our tailored solutions can optimize your process efficiency and material purity!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What safety precautions and maintenance requirements are necessary for vacuum hot press furnaces? Ensure Safe, Reliable Operation

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity