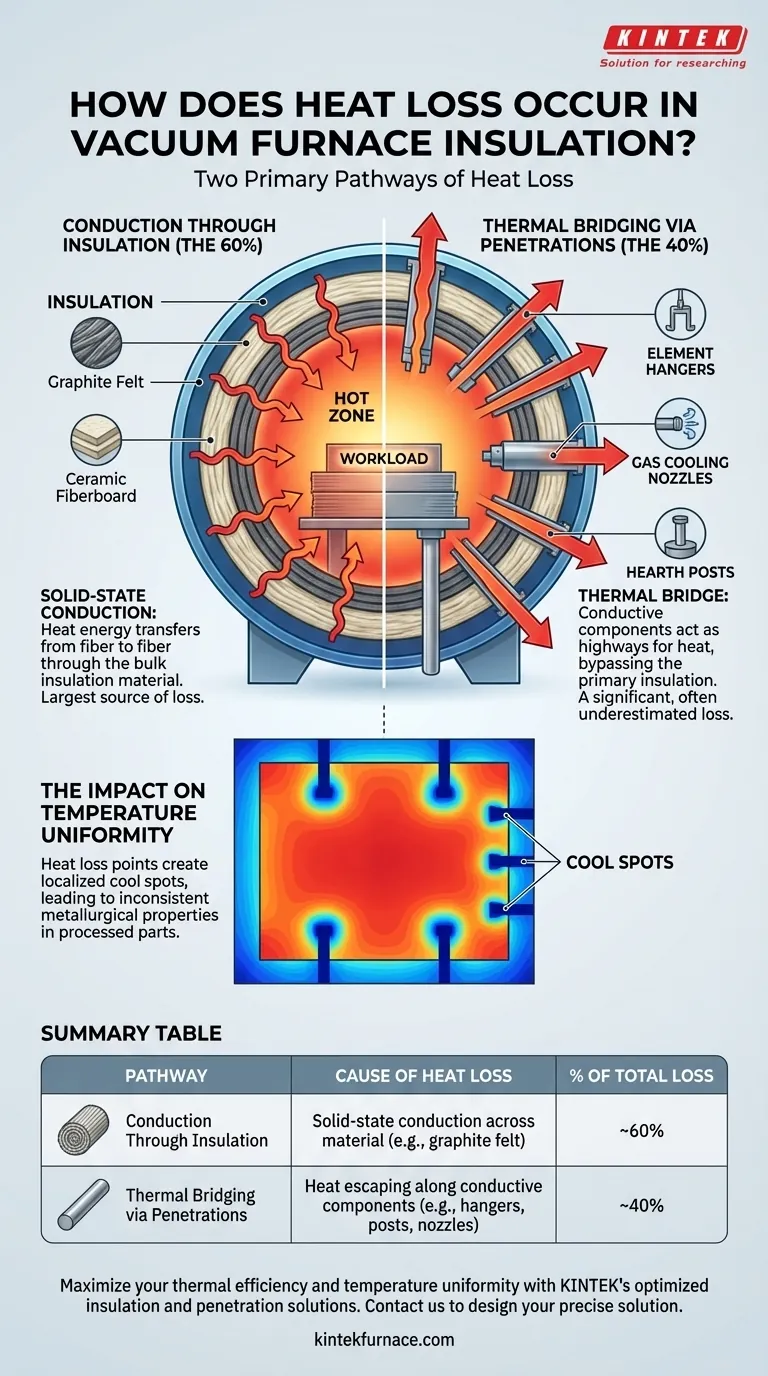

Heat loss in a vacuum furnace occurs via two distinct pathways. Roughly 60% of the thermal energy escapes through solid-state conduction across the insulation material itself. The remaining 40% is lost along "thermal bridges"—the necessary penetrations such as element hangers, cooling nozzles, and hearth posts that pass through the insulation.

While the bulk insulation material is the largest source of heat loss, a significant and often underestimated amount of energy escapes through the structural components that pierce the insulating layers. True thermal efficiency can only be achieved by addressing both of these mechanisms.

The Two Primary Pathways of Heat Loss

Understanding how a furnace loses heat is the first step toward controlling it. The energy doesn't just radiate away; it follows specific, predictable paths out of the hot zone.

Pathway 1: Conduction Through Insulation (The 60%)

The primary job of insulation, whether it's graphite felt or a ceramic fiberboard, is to resist the flow of heat. However, no material is a perfect insulator.

Heat energy will always find a way to move through the solid material, transferring from fiber to fiber. This process is known as solid-state conduction. It accounts for the majority of the heat loss in a well-designed furnace.

Pathway 2: Thermal Bridging via Penetrations (The 40%)

A thermal bridge is a path of higher conductivity that allows heat to bypass the primary insulation. In a vacuum furnace, these bridges are created by any component that must pass from the hot zone to the colder furnace shell.

These penetrations, including element hangers, hearth posts, and gas cooling nozzles, are often made of dense, conductive materials. They act as highways for heat, channeling it away from the workload and out of the system, accounting for a substantial 40% of total losses.

Understanding the Inherent Trade-offs

Managing heat loss is not about creating a perfect system, but about managing the necessary compromises of furnace design.

The Necessity of Penetrations

You cannot simply eliminate penetrations. Heating elements must be hung, the workload must be supported by a hearth, and process gases often need to be introduced or vented.

Therefore, the challenge is not removing these thermal bridges but minimizing their impact. This is achieved through careful material selection and design to create a "thermal break" wherever possible.

The Impact on Temperature Uniformity

These heat loss points are not distributed evenly. They create localized cool spots within the furnace chamber.

This lack of temperature uniformity can directly impact the quality of the processed parts, leading to inconsistent metallurgical properties. The goal of insulation is not just to save energy, but to ensure the entire workload experiences the same thermal profile.

How to Apply This to Your Furnace

Your strategy for improving thermal performance depends on where you can make the most effective changes.

- If your primary focus is the core insulation package: Ensure you are using high-quality materials with the lowest possible thermal conductivity and check for degradation, sagging, or gaps that compromise performance.

- If your primary focus is overall system efficiency: Critically evaluate every penetration, as these represent nearly half of your heat loss and are often the most overlooked opportunity for improvement.

Ultimately, an efficient vacuum furnace is a system where both the expansive insulation shields and the smallest structural penetrations are optimized to contain heat.

Summary Table:

| Pathway | Cause of Heat Loss | % of Total Loss |

|---|---|---|

| Conduction Through Insulation | Solid-state conduction across the insulation material (e.g., graphite felt) | ~60% |

| Thermal Bridging via Penetrations | Heat escaping along conductive components (e.g., element hangers, hearth posts, cooling nozzles) | ~40% |

Maximize your vacuum furnace's thermal efficiency and temperature uniformity. At KINTEK, we understand that nearly half of all heat loss occurs through structural penetrations—a critical detail often overlooked. Leveraging our exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures your furnace insulation and every penetration are optimized to minimize energy waste and ensure consistent part quality. Contact us today to discuss how we can design a solution that precisely meets your unique thermal requirements. Get in touch via our Contact Form

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance