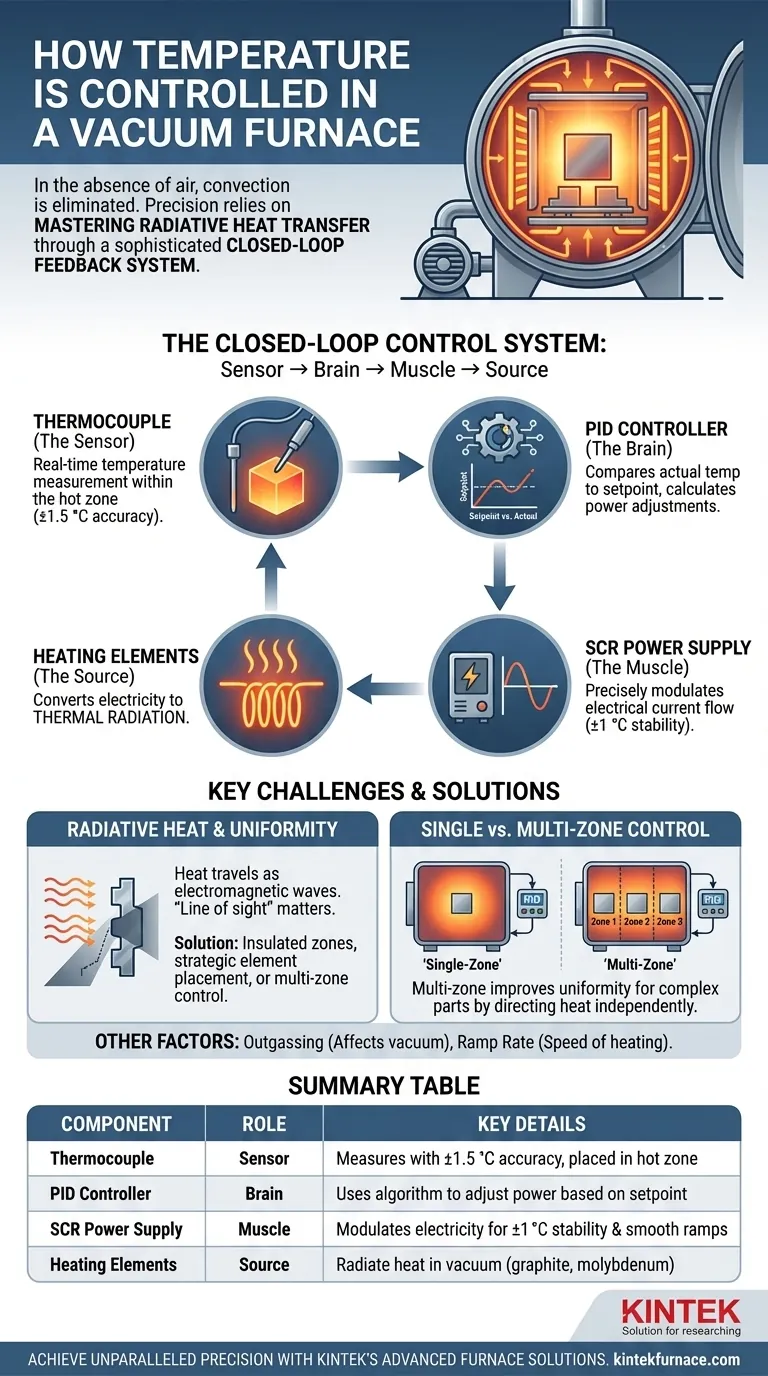

In a vacuum furnace, temperature is not merely adjusted; it is meticulously managed through a closed-loop feedback system. This system precisely controls the energy delivered to the heating elements based on real-time measurements. The core components are thermocouples that sense the temperature, a programmable controller (like a PID) that calculates the necessary adjustments, and a power regulator (like an SCR) that modifies the electrical current to the heat source.

The challenge of heating in a vacuum is the absence of air, which eliminates heat transfer by convection. Therefore, precise temperature control relies on mastering radiative heat transfer through a sophisticated electronic feedback loop to ensure the uniform, predictable results required for high-integrity processes like brazing, annealing, and sintering.

The Core Components of Temperature Control

A vacuum furnace's temperature control system functions like a highly disciplined team, with each component performing a distinct and critical role. The synergy between these parts allows for exceptional precision.

The Sensor: The Thermocouple's Role

Thermocouples are the "nerves" of the system. Placed within the furnace's hot zone, these sensors measure the temperature of the workload and surrounding environment in real-time. The accuracy of the entire system hinges on the precision and strategic placement of these thermocouples.

Modern systems can achieve measurement accuracy within ±1.5 °C, providing a reliable data stream for the controller.

The Brain: The PID Controller

The temperature controller is the "brain" of the operation. It most often uses a PID (Proportional-Integral-Derivative) algorithm.

The controller constantly compares the actual temperature measured by the thermocouple to the desired temperature setpoint defined by the user. Based on this difference, it calculates the exact amount of power the heating elements need. Advanced systems use fully automatic PLC or touch-screen interfaces for programming complex heating and cooling cycles.

The Muscle: The SCR Power Supply

If the controller is the brain, the SCR (Silicon Controlled Rectifier) power supply is the muscle. It receives the low-voltage command signal from the PID controller and precisely modulates the high-power electricity flowing to the heating elements.

This regulation is not a simple on/off switch. The SCR can deliver a continuously variable amount of power, allowing for smooth temperature ramps and incredibly stable holding temperatures, often with controllability within ±1 degree.

The Source: Heating Elements

These are the components that convert electrical energy into heat. Common materials include graphite, molybdenum wire, or resistance wire, chosen based on the furnace's maximum operating temperature.

In a vacuum, these elements transfer their energy almost exclusively through thermal radiation.

How Heat Behaves in a Vacuum

Understanding the physics of heat transfer inside a vacuum is essential to appreciating the nuances of temperature control. You are not heating air that then heats the part; you are directly heating the part with radiated energy.

The Dominance of Radiation

With no air to move heat around (convection), energy travels from the heating elements to the workpiece as electromagnetic waves, much like heat from the sun travels to Earth. This makes "line of sight" a critical factor.

Any part of the workload that is shielded from the heating elements will heat more slowly, relying on secondary radiation and conduction from hotter areas of the workload itself.

The Challenge of Temperature Uniformity

Because of the reliance on radiation, achieving temperature uniformity—ensuring the entire workpiece is at the same temperature—is a primary engineering challenge.

Furnaces use insulated hot zones and strategically placed heating elements to create an even field of radiation. For the highest precision, some furnaces use forced circulation of a rarefied inert gas (like argon or nitrogen) to introduce a small amount of convection, which can improve uniformity to within ±5 °C across the load.

Controlling the Ramp Rate

The speed at which the furnace heats up, known as the ramp rate, is also a critical control parameter. Processing delicate materials may require a slow, controlled ramp to prevent thermal shock, while other processes may benefit from a rapid ramp to the target temperature. The PID controller and SCR power supply manage this rate precisely.

Understanding the Trade-offs and Challenges

While modern vacuum furnaces offer incredible control, users must be aware of inherent challenges and system limitations to achieve optimal results.

Outgassing: The Enemy of Vacuum Integrity

As the workpiece and internal furnace fixtures heat up, they release trapped gases, a process called outgassing. This release of molecules works directly against the vacuum pump and can cause the vacuum level to degrade.

The control system must operate effectively even as the vacuum pressure changes, and operators must account for outgassing in their process recipes.

Single-Zone vs. Multi-Zone Control

The simplest furnaces use a single zone of control, where one controller and one set of thermocouples manage the entire hot zone. This is effective for small, simple parts.

However, for large or complex-shaped workloads, multi-zone control is superior. These systems divide the hot zone into multiple independent areas, each with its own thermocouple and PID control loop. This allows the system to direct more heat to areas that are lagging and less to areas that are overheating, achieving far better temperature uniformity.

The Limits of Measurement

While thermocouples are highly accurate, they are not perfect. Their placement is critical; a thermocouple measuring the temperature of an open space may not reflect the true temperature at the core of a dense workload. Experienced operators learn to map their furnace and understand the relationship between the thermocouple reading and the actual part temperature.

Making the Right Choice for Your Goal

The right temperature control strategy depends entirely on your material, part geometry, and desired outcome.

- If your primary focus is process repeatability: Your priority should be a system with a high-quality PID controller and a stable SCR power supply to ensure every cycle runs identically.

- If your primary focus is treating large or complex parts: A furnace with multi-zone heat control is non-negotiable for achieving the required temperature uniformity.

- If your primary focus is processing sensitive materials: Ensure the furnace's control system allows for precise programming of the heating and cooling ramp rates to prevent thermal shock.

Ultimately, mastering temperature control in a vacuum furnace is the key to mastering the final properties of your material.

Summary Table:

| Component | Role | Key Details |

|---|---|---|

| Thermocouple | Sensor | Measures temperature with ±1.5 °C accuracy, placed in hot zone |

| PID Controller | Brain | Uses algorithm to adjust power based on setpoint and feedback |

| SCR Power Supply | Muscle | Modulates electricity for ±1 °C stability and smooth ramps |

| Heating Elements | Source | Radiate heat in vacuum, made from graphite or molybdenum |

Ready to achieve unparalleled precision in your high-temperature processes? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor our products to meet your unique experimental needs—ensuring optimal temperature control for brazing, annealing, and sintering. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance